Bearing device for wheel

A bearing device and wheel technology, applied in bearing assembly, bearings, axles, etc., can solve the problems of unrealistic, large equipment, complicated management, etc., and achieve the effect of rapid and easy quality management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

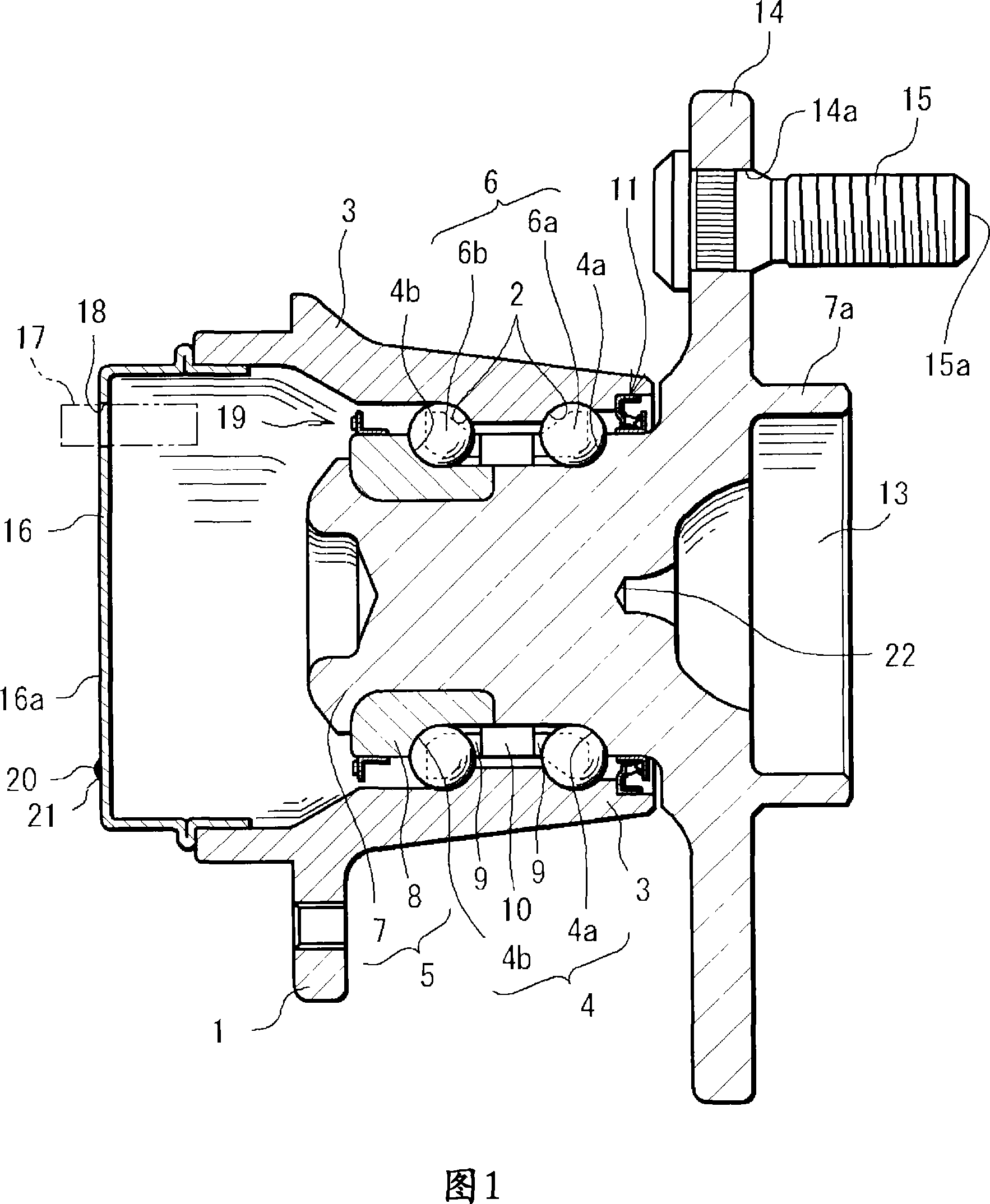

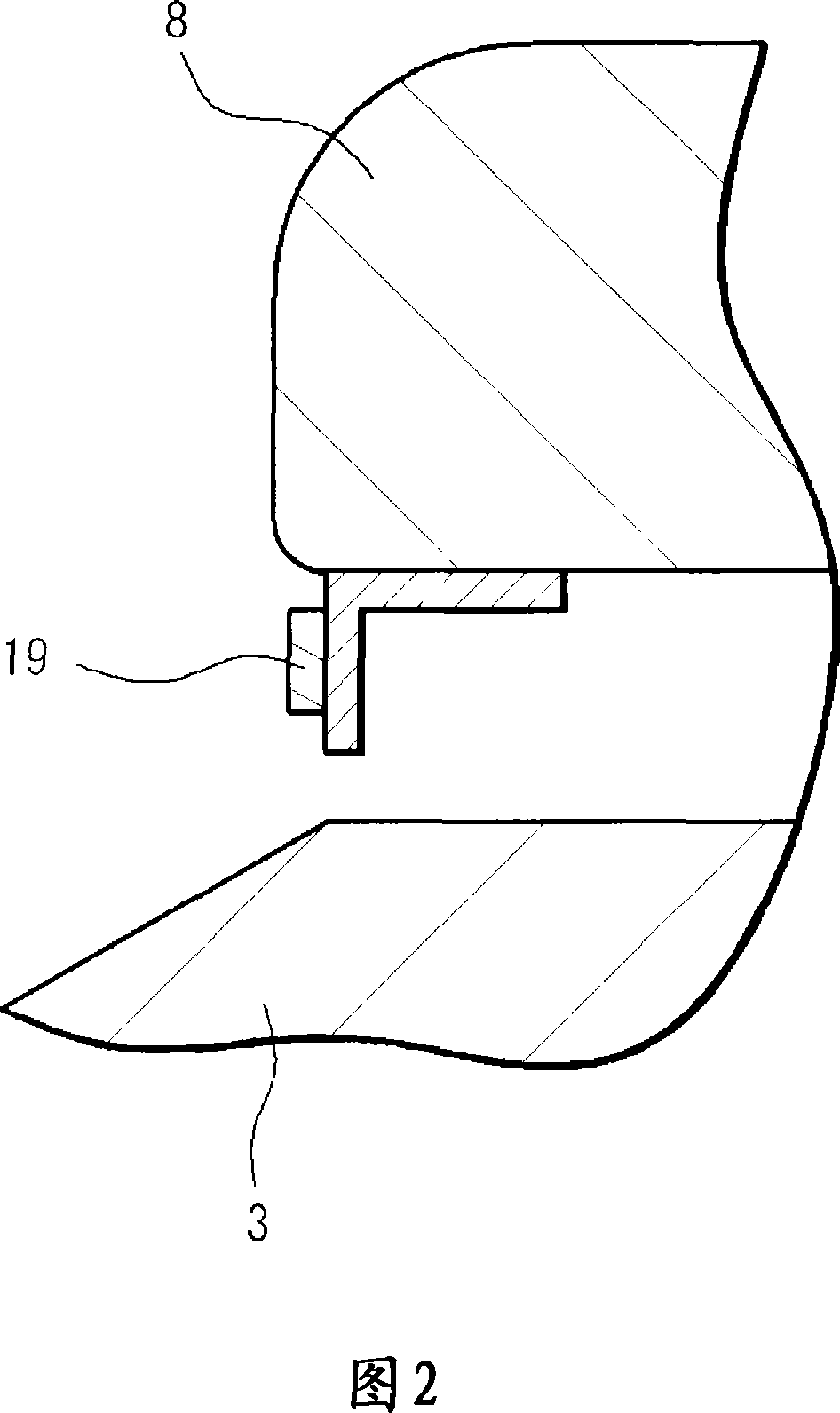

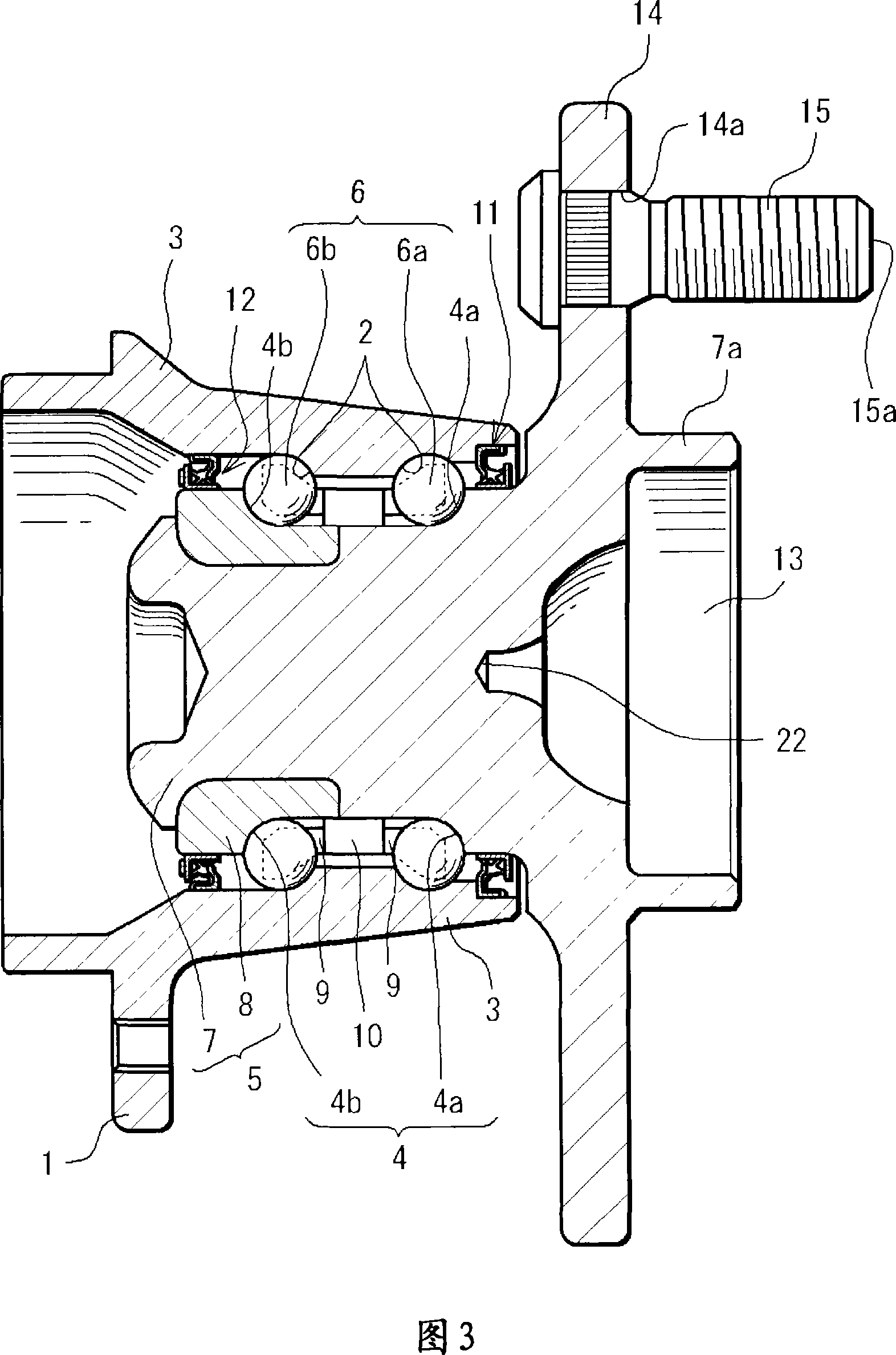

[0021] Hereinafter, embodiments of the bearing device of the present invention will be described in detail with reference to the drawings.

[0022] FIG. 1 shows a bearing device according to an embodiment of the present invention, which is a wheel bearing device on the driven wheel side of a vehicle. The above-mentioned bearing device includes: an outer ring member 3 fixed to the vehicle body side by means of a vehicle body mounting flange 1, and has a double-row outer ring raceway surface 2 on its inner peripheral surface; an inner ring member 5 connected to the vehicle body. The outer ring member 3 is concentrically arranged on the inner diameter side of the outer ring member 3, and has a double-row inner ring raceway surface 4 on its outer peripheral surface; balls 6 are sandwiched between the outer ring member in a freely rolling manner. 3 and the double row of rolling elements between the raceway surfaces 2, 4 of the inner ring member 5. The inner ring member 5 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com