Chute, apparatus for feeding sheet, and sheet wrapper

A technology of feeding device and chute, which is applied in the field of chute, can solve the problems such as bending of the sheet to be packaged, unusable packaging body, and inability to be packaged with light sheet material, so as to suppress manufacturing cost, improve removal performance, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

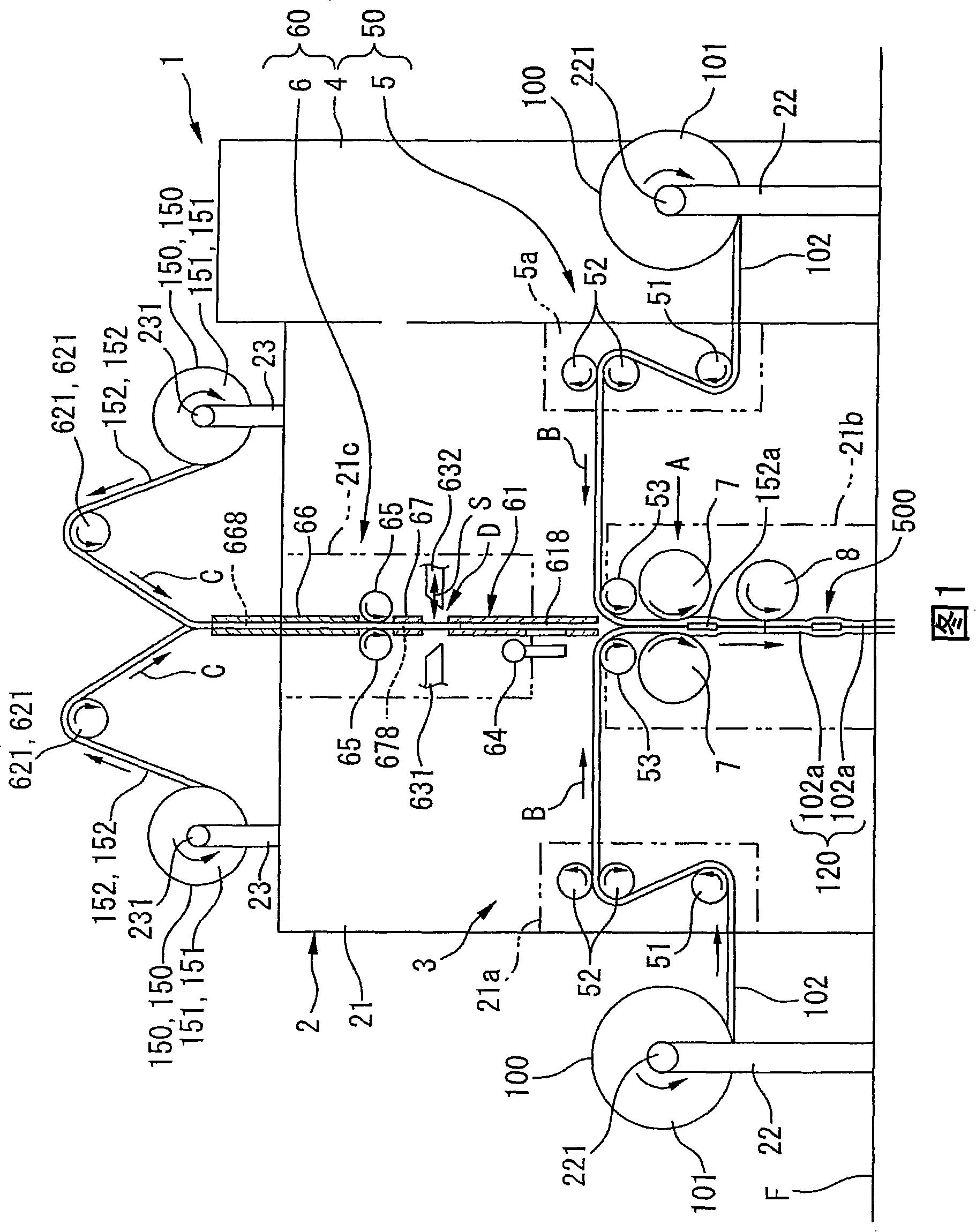

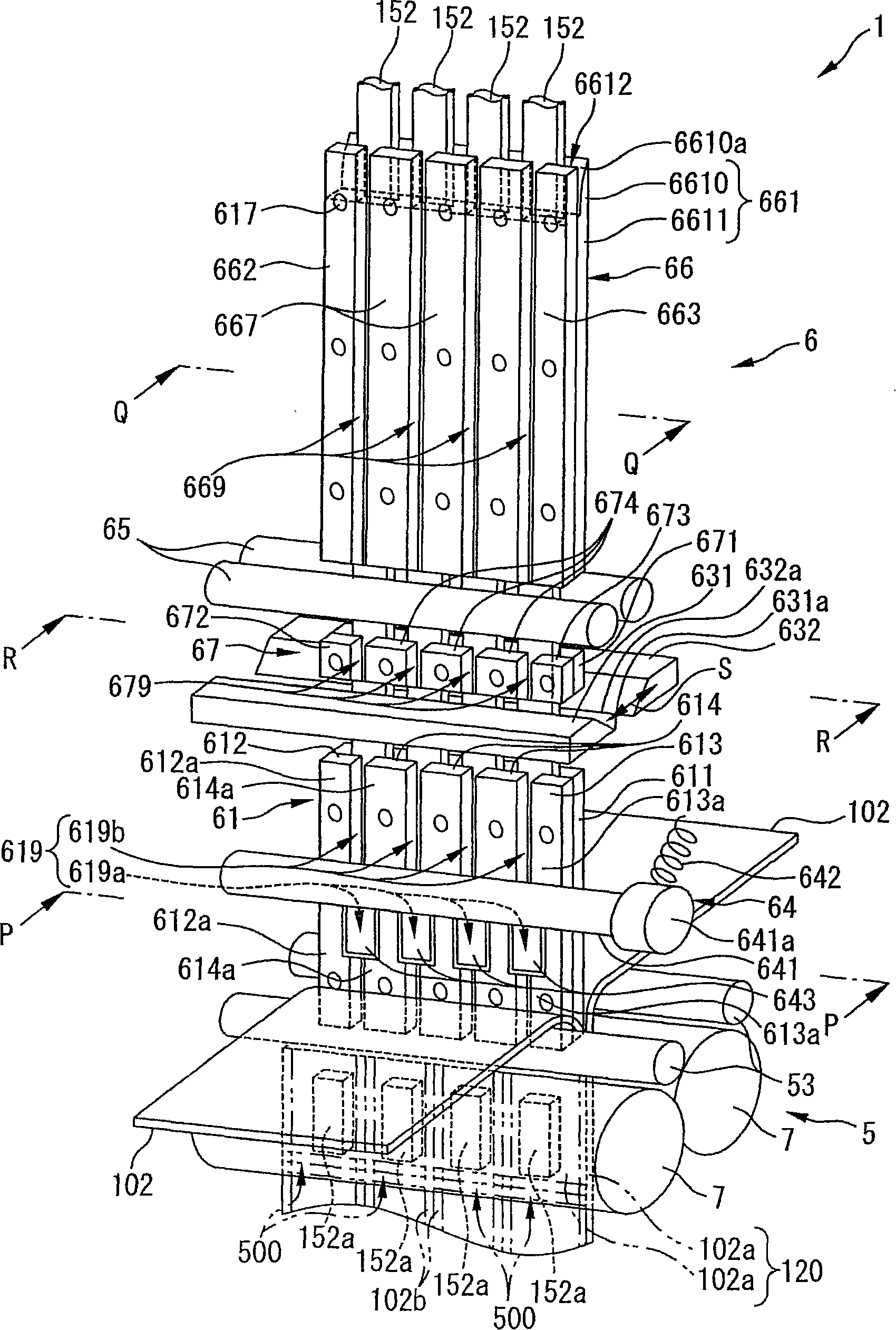

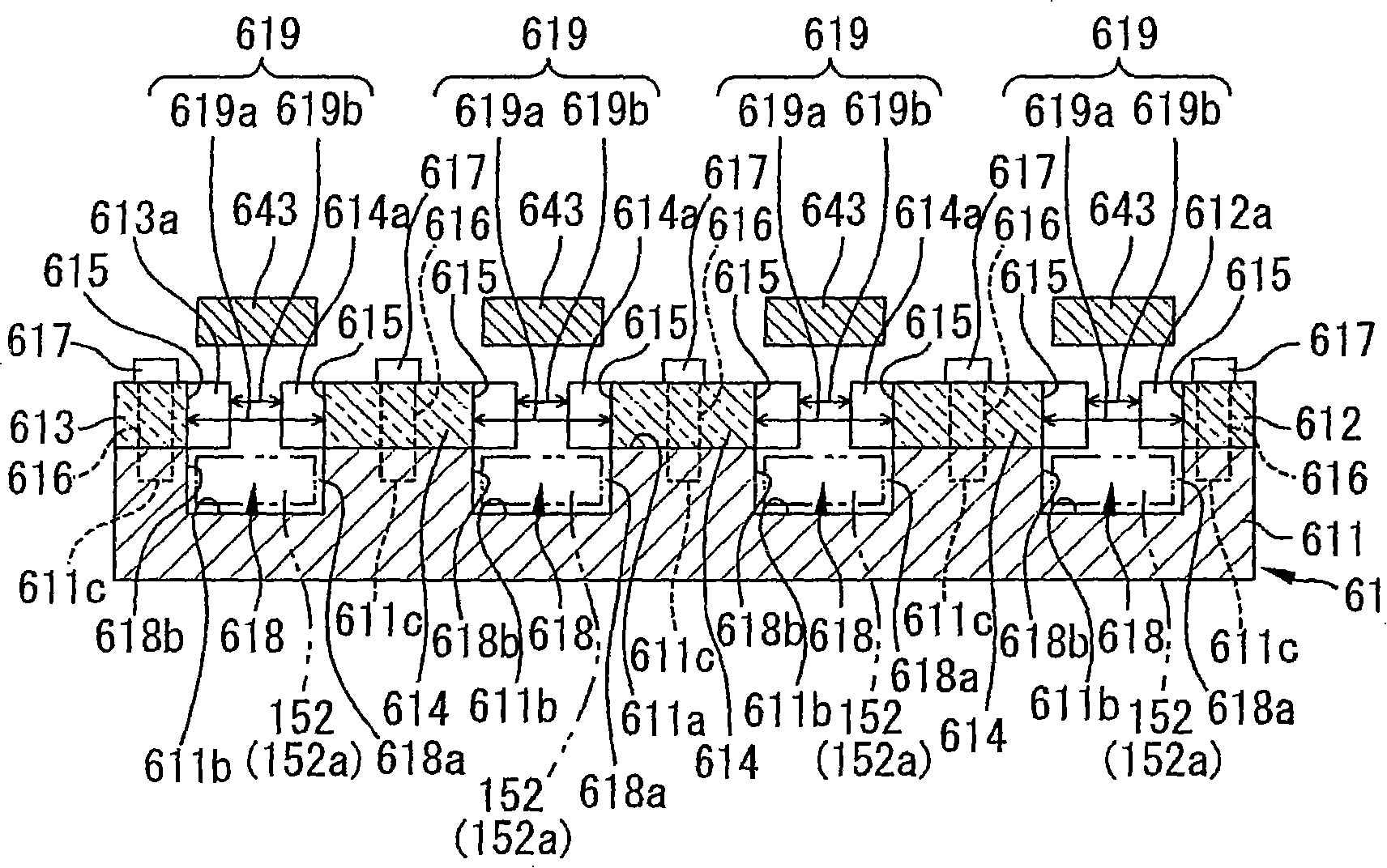

[0061] figure 1 It is a schematic diagram which shows the sheet packaging machine 1 which concerns on 1st Embodiment of this invention. This packaging machine 1 is a four-row packaging machine that manufactures four packages 500 at a time. This package 500 is constituted by the packaging bag 120 and the sheet to be packaged 152a. Furthermore, the packaging bag 120 is comprised from a pair of packaging material 102a, 102a. In this packaging machine 1, a pair of packaging material rolls 100, 100 and four rolls of sheets to be packaged 150, 150 are employed as packaging equipment.

[0062] The packaging material rolls 100 , 100 each have a reel 101 and a packaging material blank 102 wound on the reel 101 . like figure 2 As shown, the packaging material blank 102 is formed by connecting the packaging materials 102a in four rows in the horizontal direction, and the packaging materials 102a in the four rows in the horizontal direction are connected together in a plurality in th...

no. 2 approach

[0158] Figure 7 It is a perspective view showing main parts of a sheet packaging machine 300 according to a second embodiment of the present invention. In this embodiment, the same reference numerals are attached to the same parts as those in the first embodiment, and the different parts will be mainly described. This sheet packaging machine 300 is a two-line packaging machine that manufactures two packages 500 at a time. Furthermore, this sheet packaging machine 300 has a sheet supply device 360 and a packaging device 350 as in the first embodiment.

[0159] Similar to the first embodiment, the packaging device 350 has: a packaging material conveying device that conveys the packaging material blanks 302, 302 (packaging materials 102a, 102a); and a packaging material position detection sensor that detects the position of the packaging materials 102a, 102a during conveyance. ; Two rows of corresponding heat sealing machines 70, 70; two rows of corresponding cutting machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com