Complex electrode structure of longitudinal stream gas discharge system

A technology of gas discharge and longitudinal flow, which is applied in the direction of circuits, electrical components, laser components, etc., can solve problems such as DC discharge discharge mode and electrode structure, and achieve the effect of increasing injection power, increasing concentration, and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

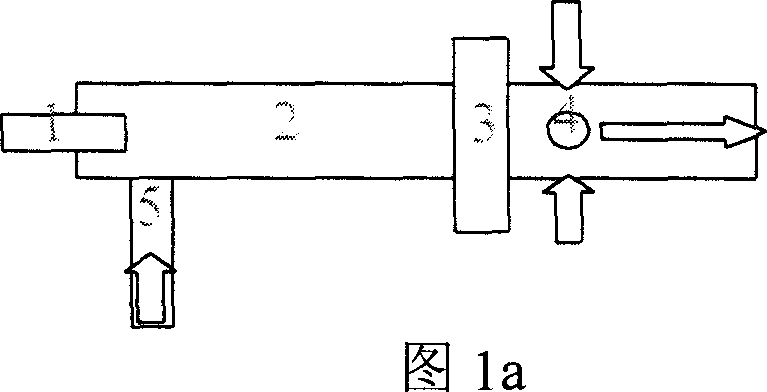

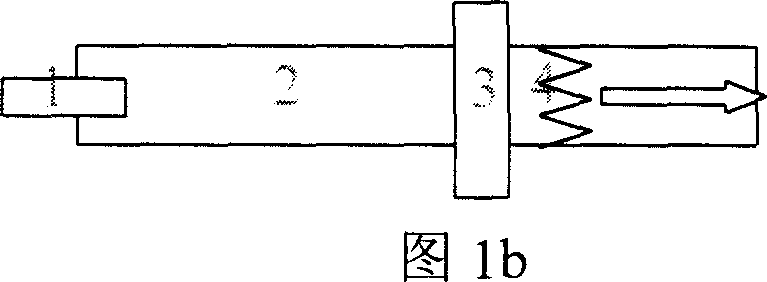

[0021] Please refer to Fig. 1, the inventive device consists of an anode, a quartz discharge tube, and a double cathode structure. The anode 1 is a cylindrical cavity structure, cooled by circulating water inside, connected to the quartz tube 2 through a plexiglass sealing sleeve, the first cathode 3 is an annular cavity structure, and internally circulated for cooling, and is also connected to the quartz tube 2 through a plexiglass sealing sleeve. Connected, the second cathode 4 is a spiral coil structure, placed vertically in the downstream transition section of the air flow, and internally circulated for cooling. 5 is an air inlet for flowing gas. The gas flows through the discharge tube, flows out from the center of the cathode 3 ring, and collides with the cathode 4 to increase disturbance and strengthen mixing.

[0022] The above electrode structure can be applied to the stable discharge of flowing gas, increasing the concentration of active particles and improving the u...

Embodiment 2

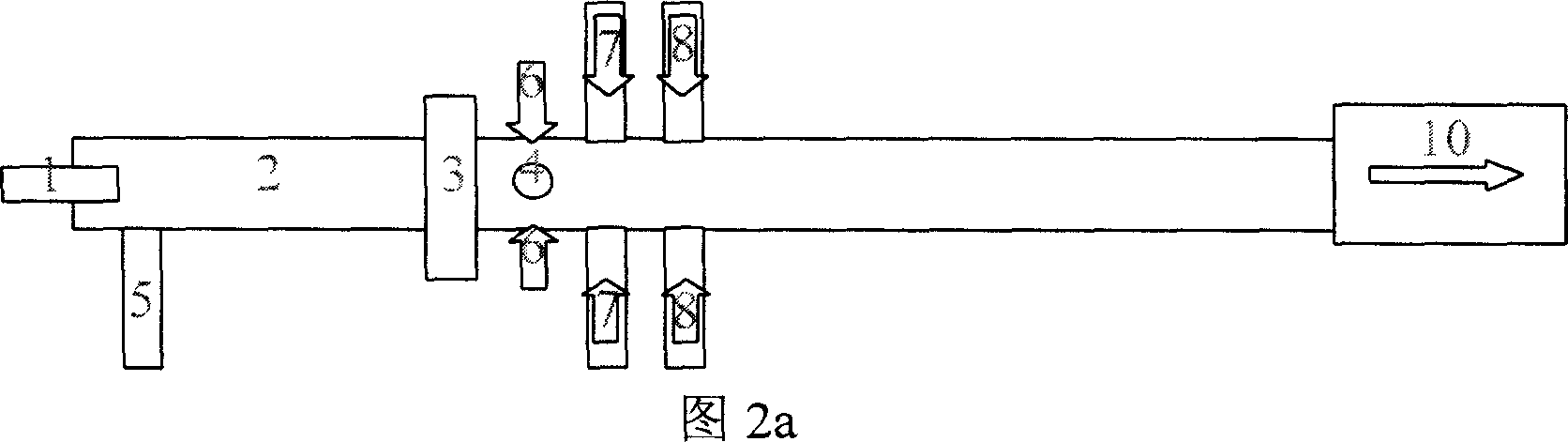

[0024] The following uses the application of the F / DCl / HI / HN3 all-gas-phase iodine laser system as an example to illustrate the method of using the electrode structure of the present invention.

[0025] The applicant used the electrode structure of the mixed reaction gas discharge system to generate active particle fluorine atoms, and applied the invention to the F / DCl / HI / HN3 all-gas-phase iodine laser system for the first time, and studied the discharge characteristics and injection power of the gas Condition.

[0026] Please refer to Figure 2. Since the F / DCl / HI / HN3 all-gas-phase iodine laser system is a mixed reaction of four gas streams to generate excited iodine atoms, it is possible to perform gain measurement and light demonstration. In this embodiment, the electrode structure of the mixed reactive gas flow discharge system of the present invention is used to perform DC discharge on the mixed gas of NF3 / He to generate active particle fluorine atoms, and the main gas flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com