Mask loading technology

A mask plate and process technology, applied in the field of photolithography, can solve the problems of reducing loading efficiency, failure to reduce errors, difficulties, etc., and achieve the effects of reducing computational complexity, improving loading accuracy, and reducing the number of repetitions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The reticle loading process of the present invention will be further described in detail below with reference to the accompanying drawings.

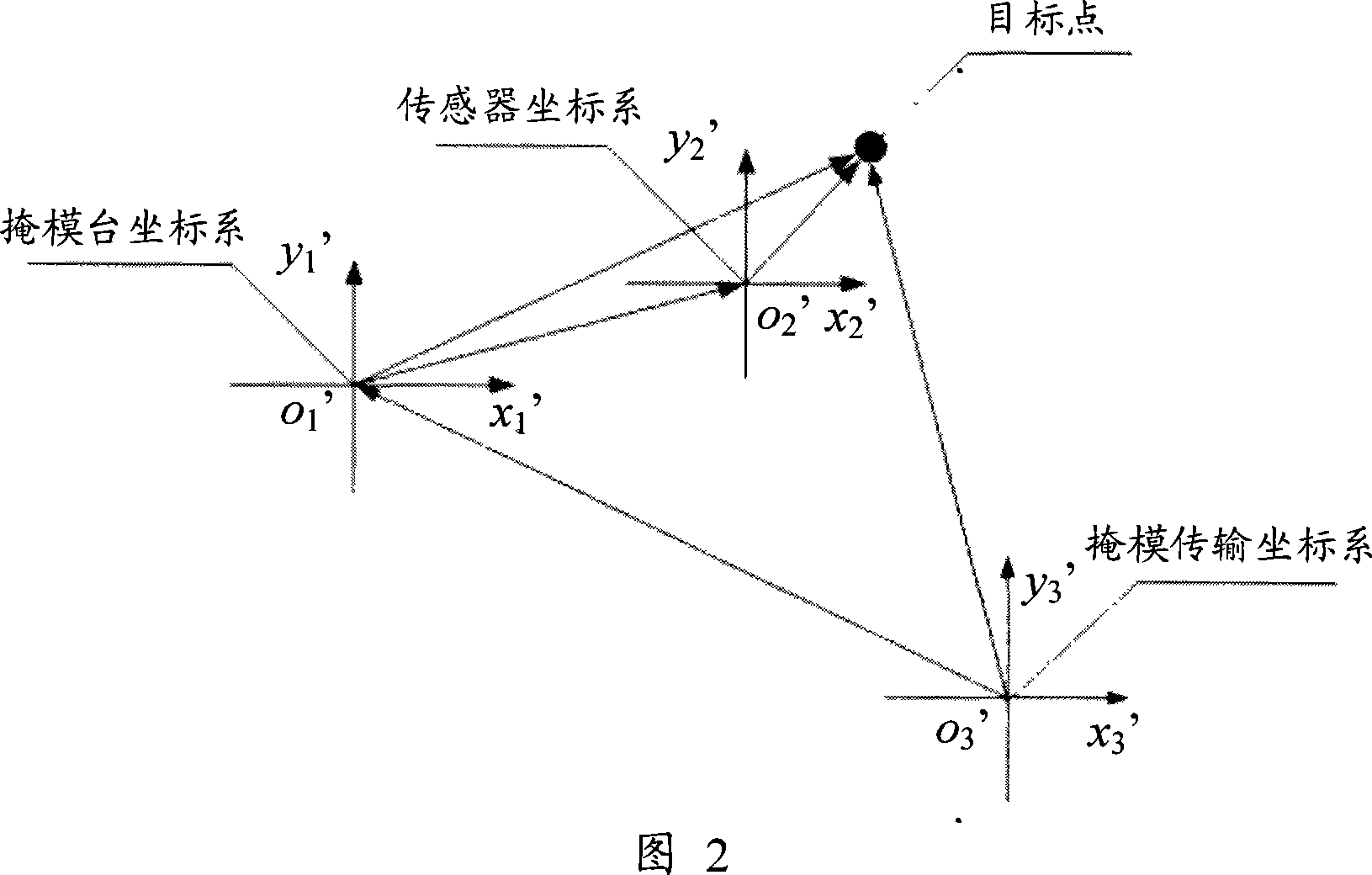

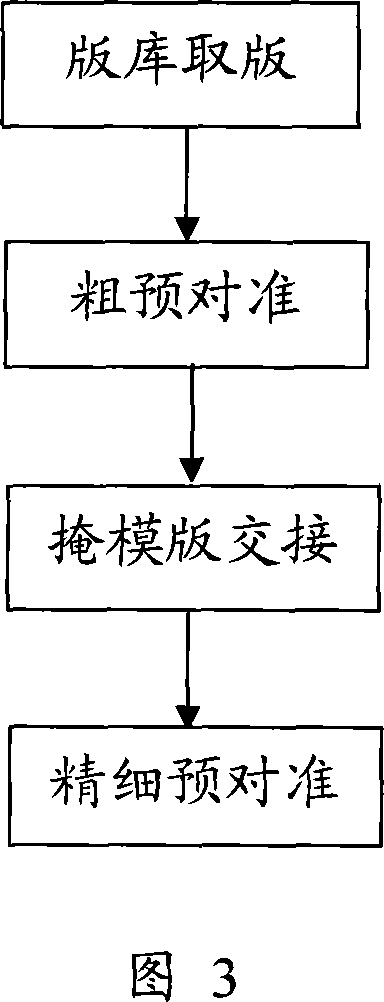

[0029] As shown in FIG. 3 , the reticle loading process of the present invention includes four processes: receptacle retrieval, rough pre-alignment, reticle transfer, and fine pre-alignment. Among them, the process of plate picking and rough pre-alignment from the plate library is completed on the mask transmission system, the reticle handover process is completed by the cooperation of the mask transmission system and the mask table system, and the fine pre-alignment process is completed on the mask table system.

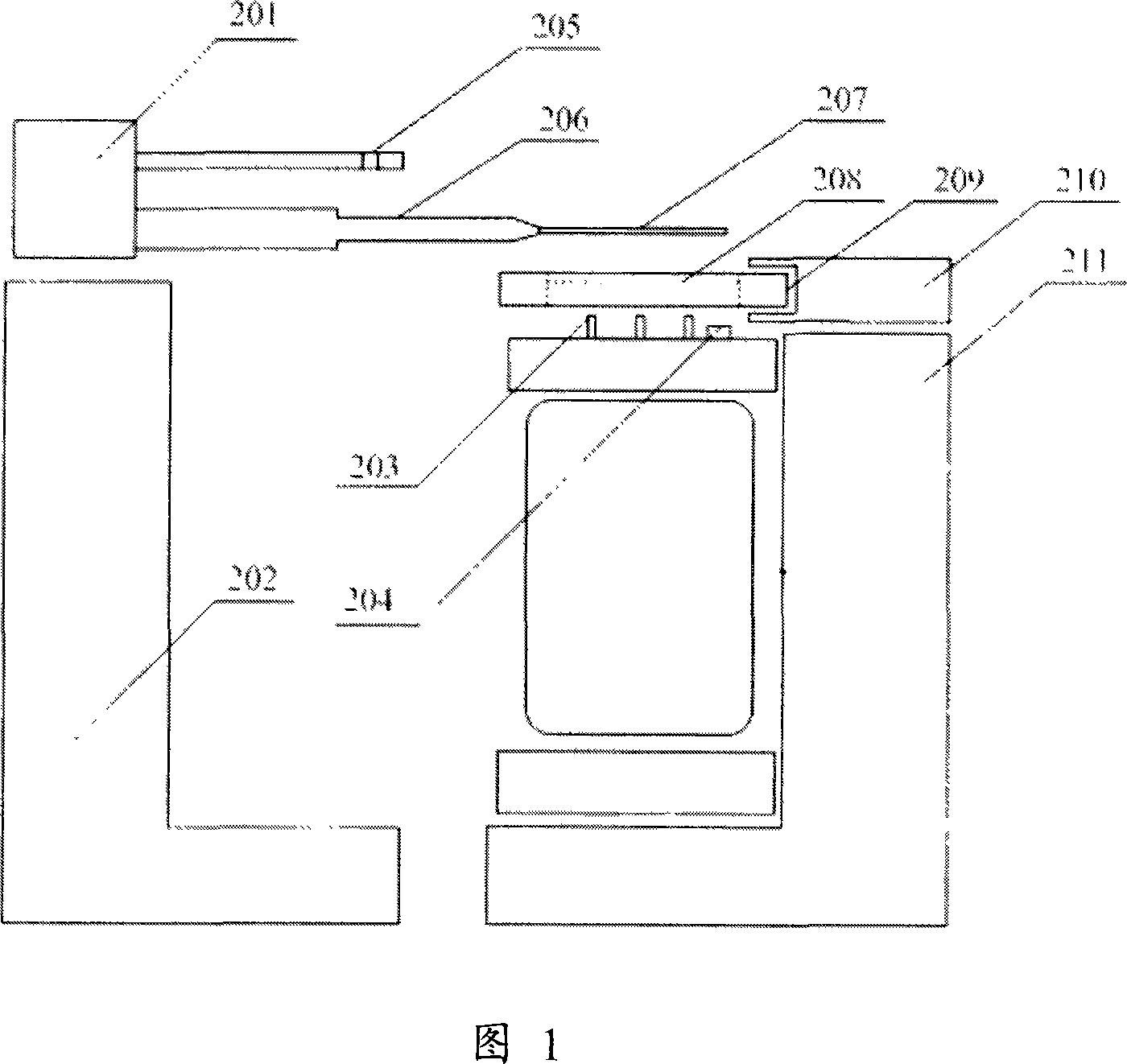

[0030] With reference to FIG. 1 , when performing the reticle loading process, the mask transfer system 202 firstly performs reticle picking and rough pre-alignment to achieve a certain reticle loading accuracy, and then cooperates with the mask stage system 211 to realize the reticle loading process. The stencil is han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com