Button type lithium-manganese battery automatic production line

An automated production line, button-type lithium-manganese battery technology, applied in the field of automatic battery production lines, can solve the problems of low production efficiency of button-type lithium-manganese batteries, and achieve the effects of cost reduction and efficiency increase, convenient manufacturing, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following structural drawings and embodiments further illustrate the present invention.

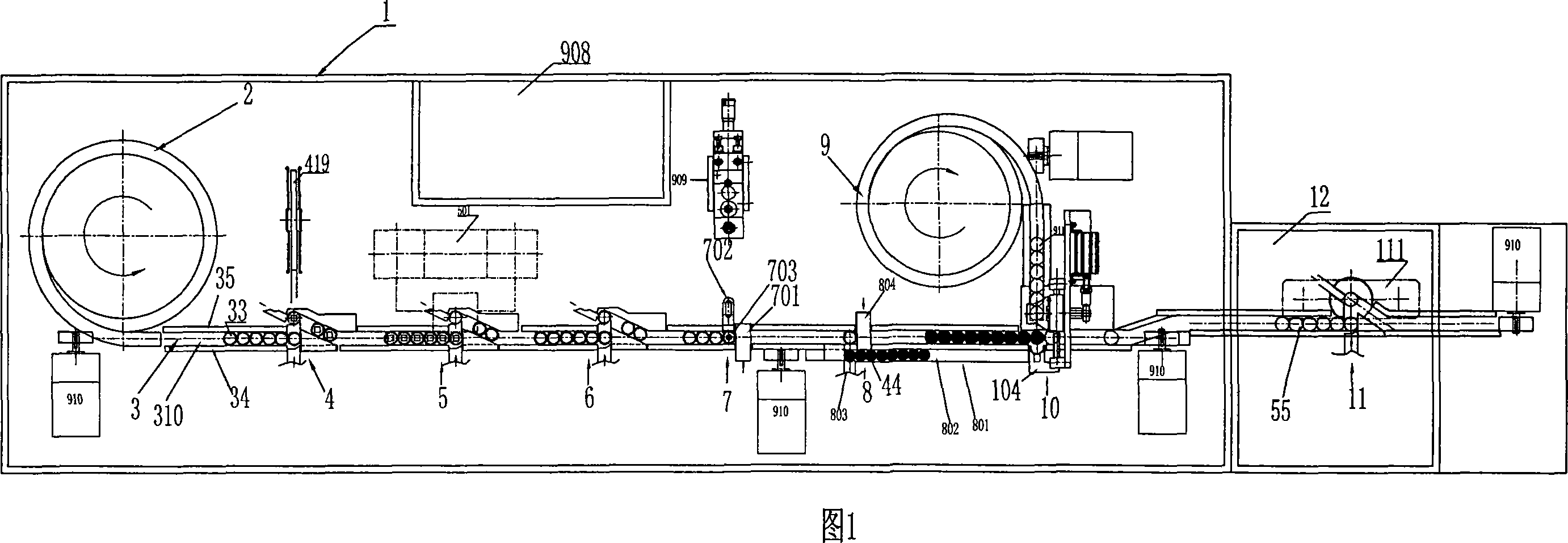

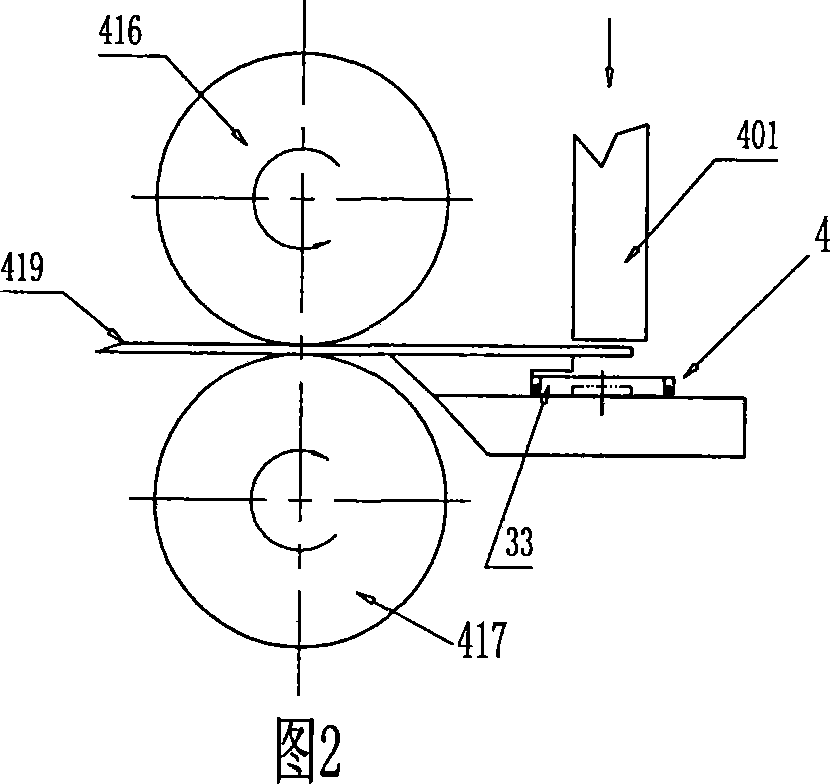

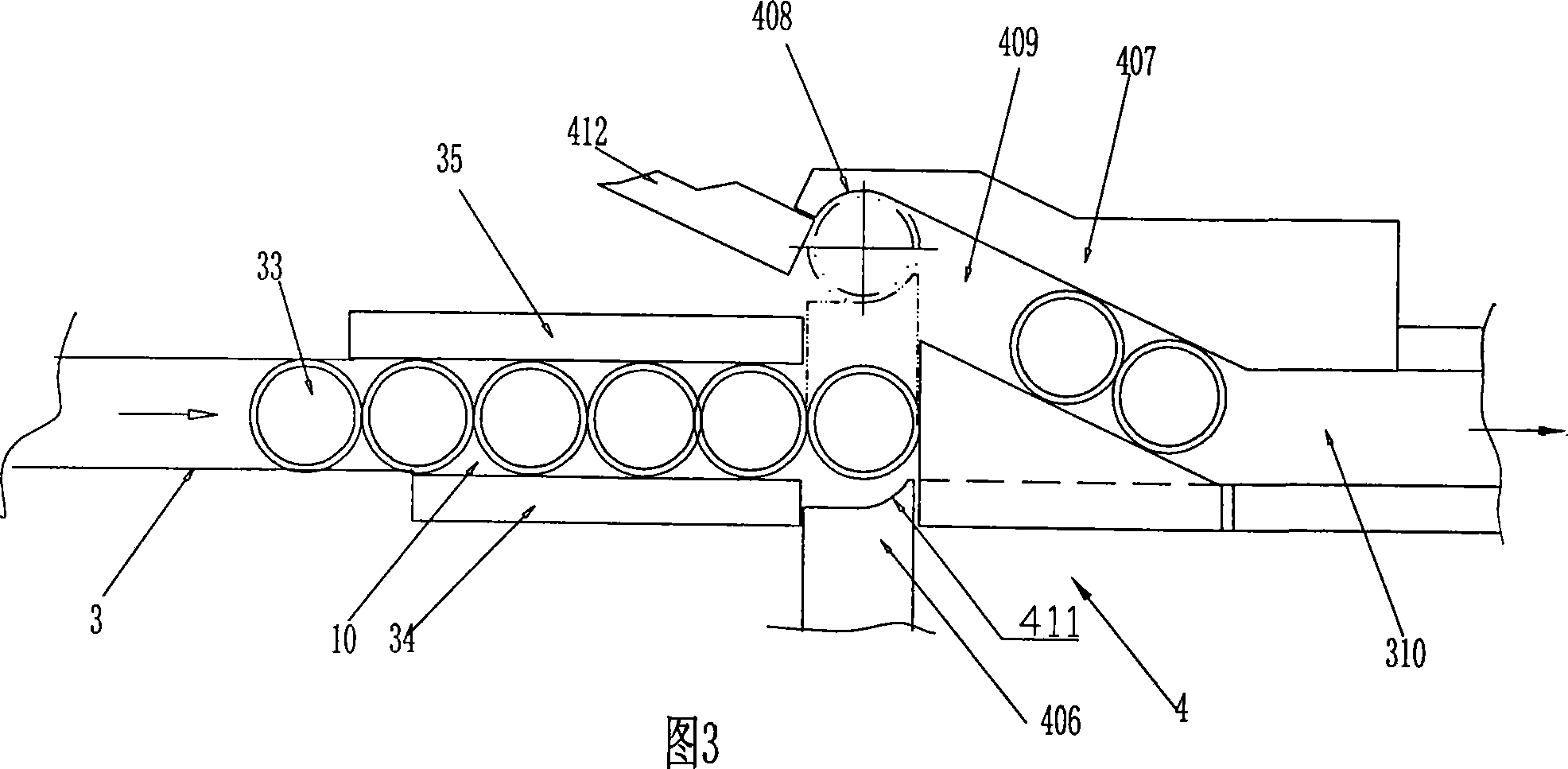

[0034] As shown in Figure 1-11.

[0035] An automatic production line for button-type lithium-manganese batteries, including a vacuum drying glove box 1, a negative electrode shell vibration discharge machine 2, an anode shell vibration discharge machine 9, an anode shell vibration discharge machine 9 and a negative electrode shell vibration discharge machine Machines 2 are all installed in a vacuum drying glove box 1, and a conveyor belt 3, a lithium belt cutting device 4, a lithium material stamping forming device 5, a separator stamping forming device 6, an electrolytic Liquid filling device 7, anode discharge device 8, anode casing and negative electrode casing combination device 10, and battery stamping and sealing device 11, guide plates 34, 35 and guide plates 34 for guiding the negative electrode casing 33 are installed on both sides of the conveyor belt 3 , 35 to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com