Battery with nonaqueous electrolyte

A non-aqueous electrolyte and battery technology, applied in non-aqueous electrolyte batteries, battery electrodes, circuits, etc., can solve problems such as insufficient pulse discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

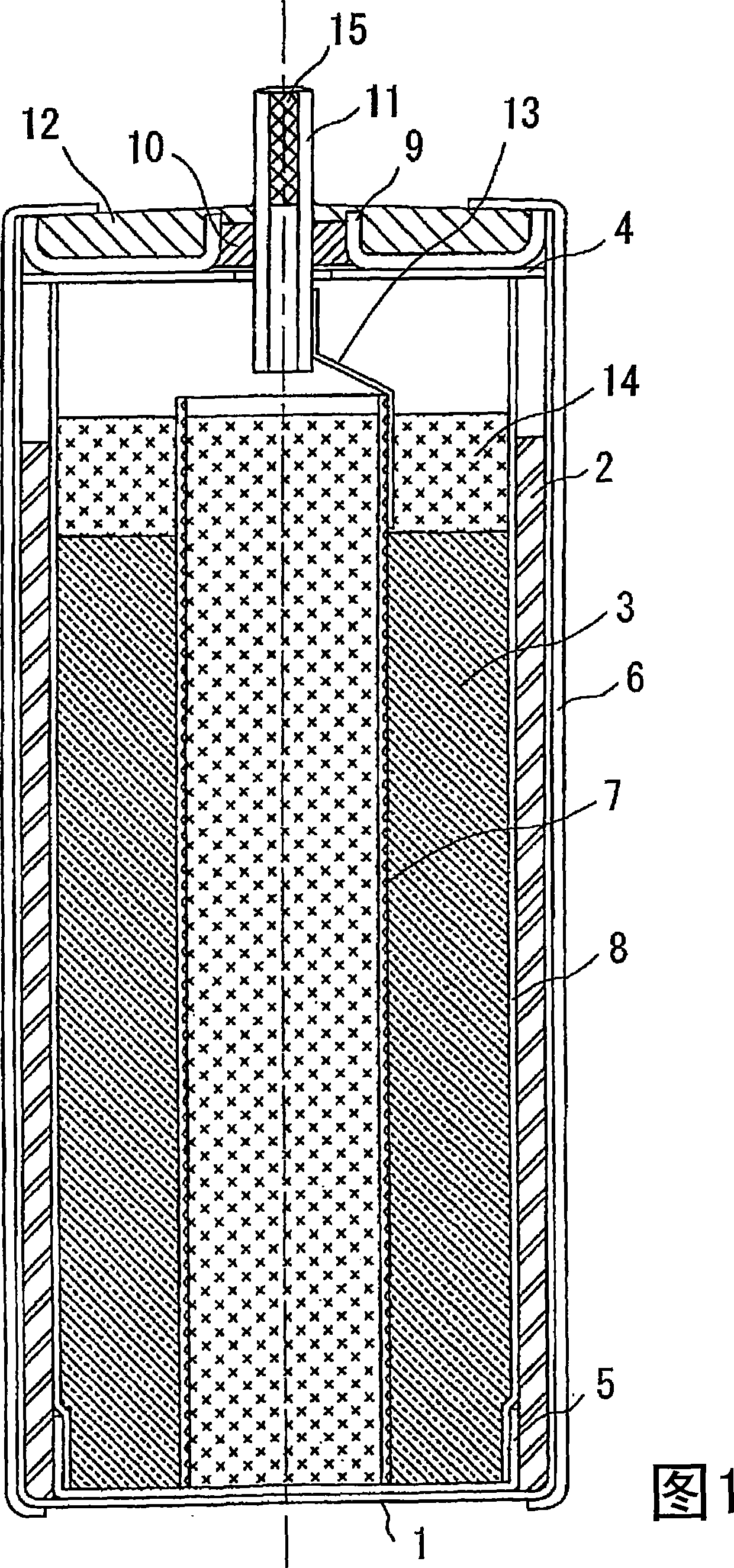

[0030] Fig. 1 shows a cross-sectional view of a battery according to an embodiment of the present invention and a comparative example. Fig. 1 is a cross-sectional view of a thionyl chloride-lithium battery of A specification in which lithium is used as a negative electrode material and thionyl chloride is used as a positive electrode material.

[0031] In Figure 1, 1 is a stainless steel battery can with a diameter of 16 mm that also serves as a negative terminal. A cylindrical negative electrode 2 is crimped on the inner surface of the battery can. 3 is a porous carbon positive electrode body, which is made of acetylene black 45 Mass%, furnace black 45% by mass, PTFE 10% by mass are mixed with a mixture of water and ethanol, and then the mixed object is formed around the positive electrode current collector 7 to have an outer diameter of 10mm and a height of 35mm , It is obtained by vacuum drying at 150°C for 8 hours. The positive electrode current collector 7 is obtained by form...

Embodiment 2

[0036] Except that the additive concentration of bismuth chloride was set to 0.07 mmol / kg, the battery was produced in the same manner as in Example 1.

Embodiment 3

[0038] Except that the concentration of bismuth chloride added was 0.4 mmol / kg, it was the same as in Example 1, and a battery was produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com