Combined fork-type blade-root milling cutter

A combined and fork-shaped technology, which is applied in the direction of milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of less indexing times, scrapped cutter bodies, and short tool life, so as to increase indexing times and prolong service life , The effect of high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

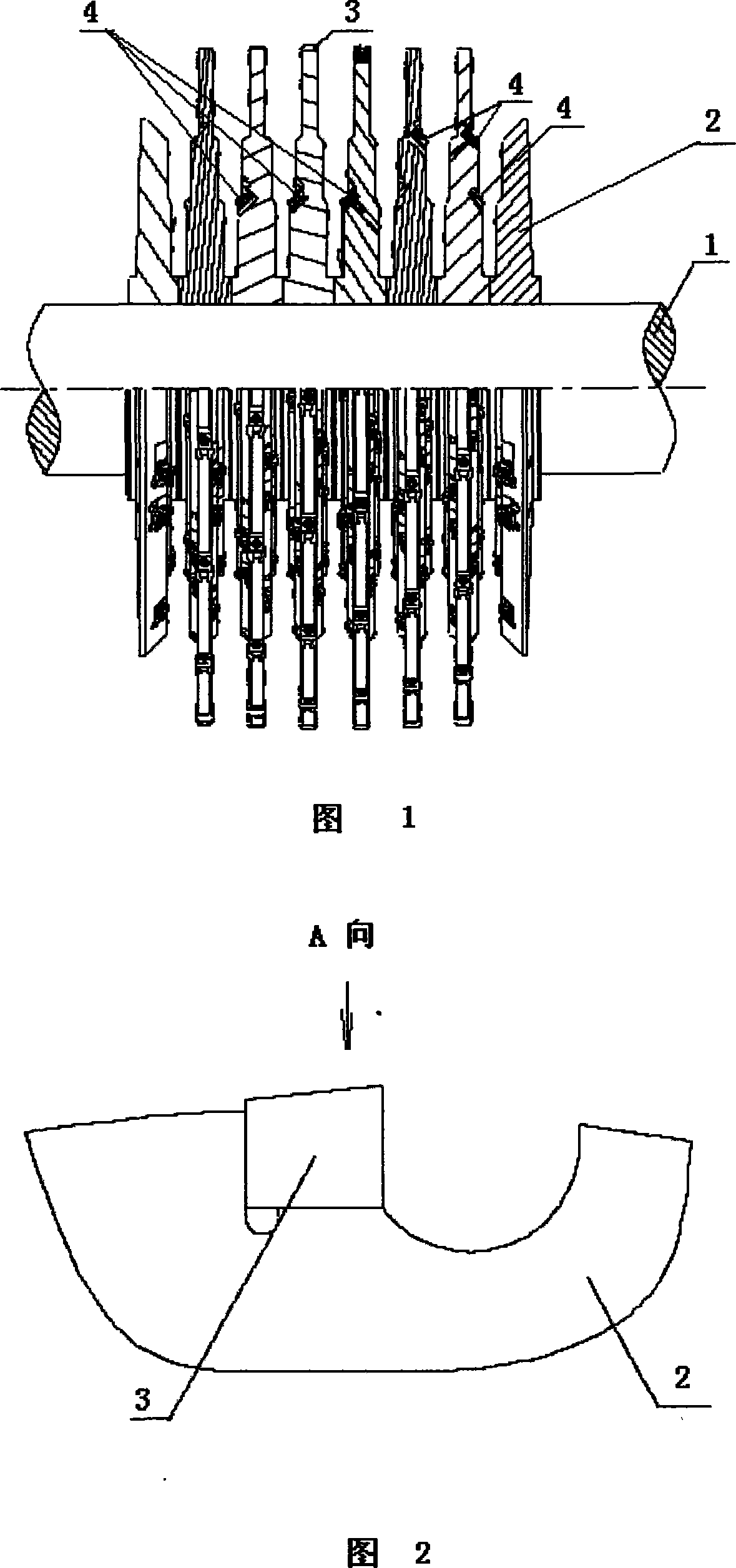

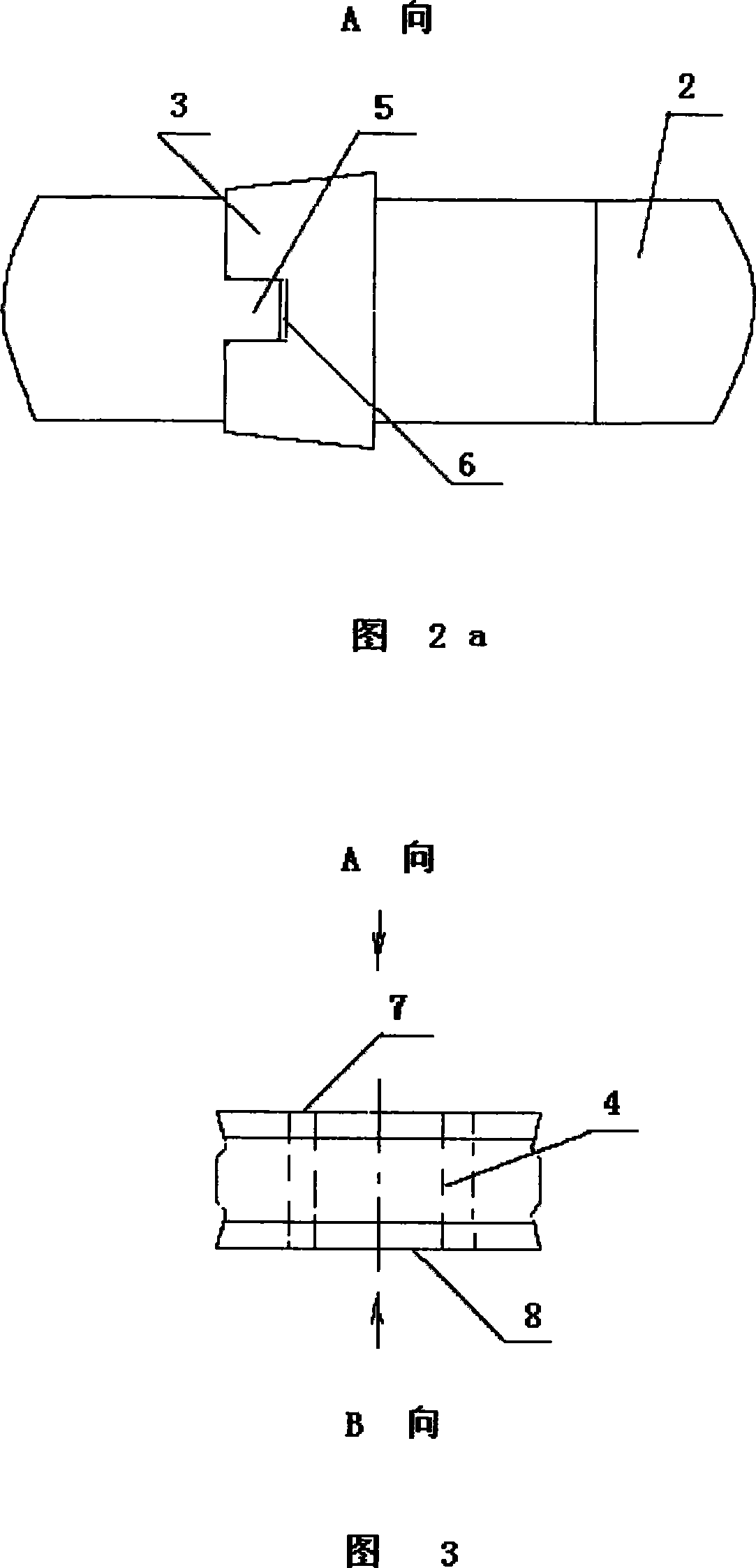

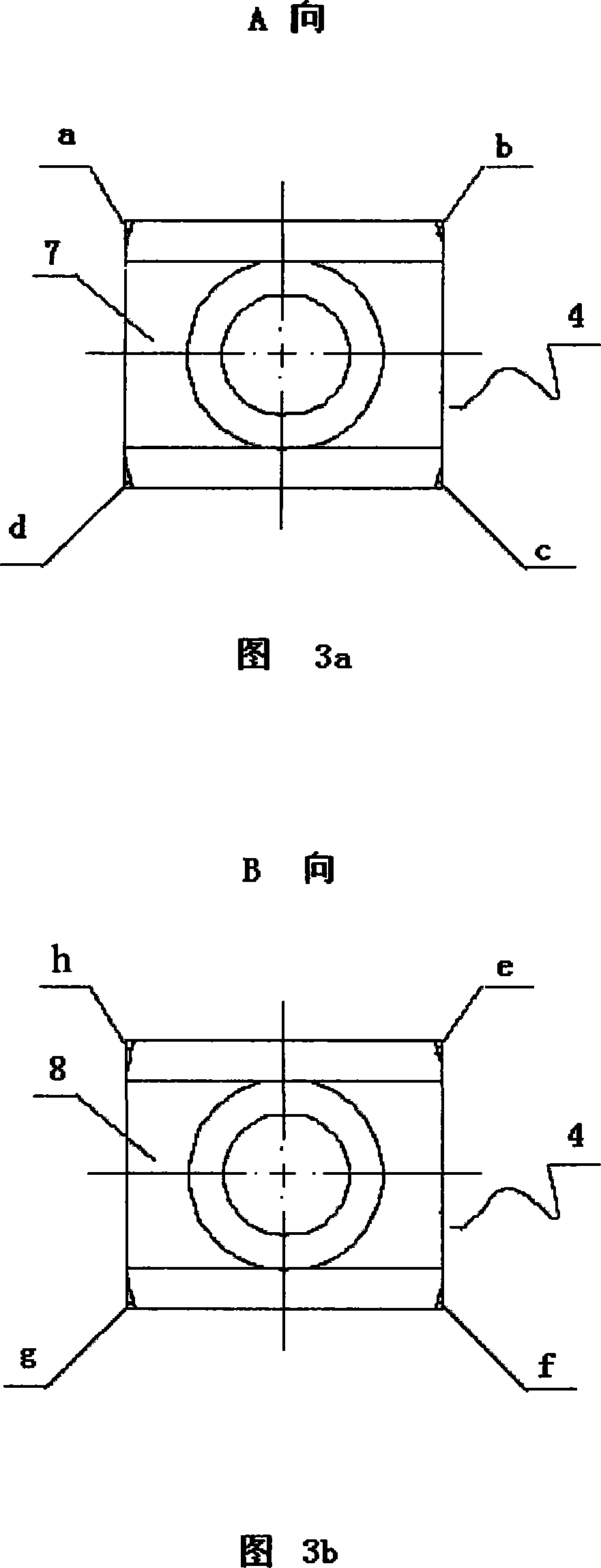

[0016] Below in conjunction with accompanying drawing, technical scheme of the present invention is described further:

[0017] As shown in Figure 1, the combined fork-type blade root milling cutter of the present invention consists of a rotating shaft 1, a disc-shaped cutter body 2, blades 3 installed on the outer edge of the disc-shaped cutter body 2 and distributed along the circumference, and installed on both sides of the disc-shaped cutter body 2 The disk surface consists of 4 indexable inserts. On each disc-shaped cutter body 2, according to the difference in the number of blade fork-shaped blade root grooves, more than two disk-shaped cutter bodies 2 can be installed on the rotating shaft 1. According to the shape characteristics of the blade fork-shaped blade root grooves, each At least two indexable inserts 4 are installed in the circumferential direction at different diameters of the disc surfaces on both sides of a disc-shaped cutter body 2 . The disk-shaped cutte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com