Technology for combining wind-duct using bundling belt

A technology of strapping and air ducts, applied in applications, tubular objects, household appliances, etc., can solve the problems of affecting the use effect of ventilation ducts, poor bonding firmness of ventilation ducts, and poor reliability, so as to ensure the effect of cooling and heating, The effect of good sealing and large connection surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

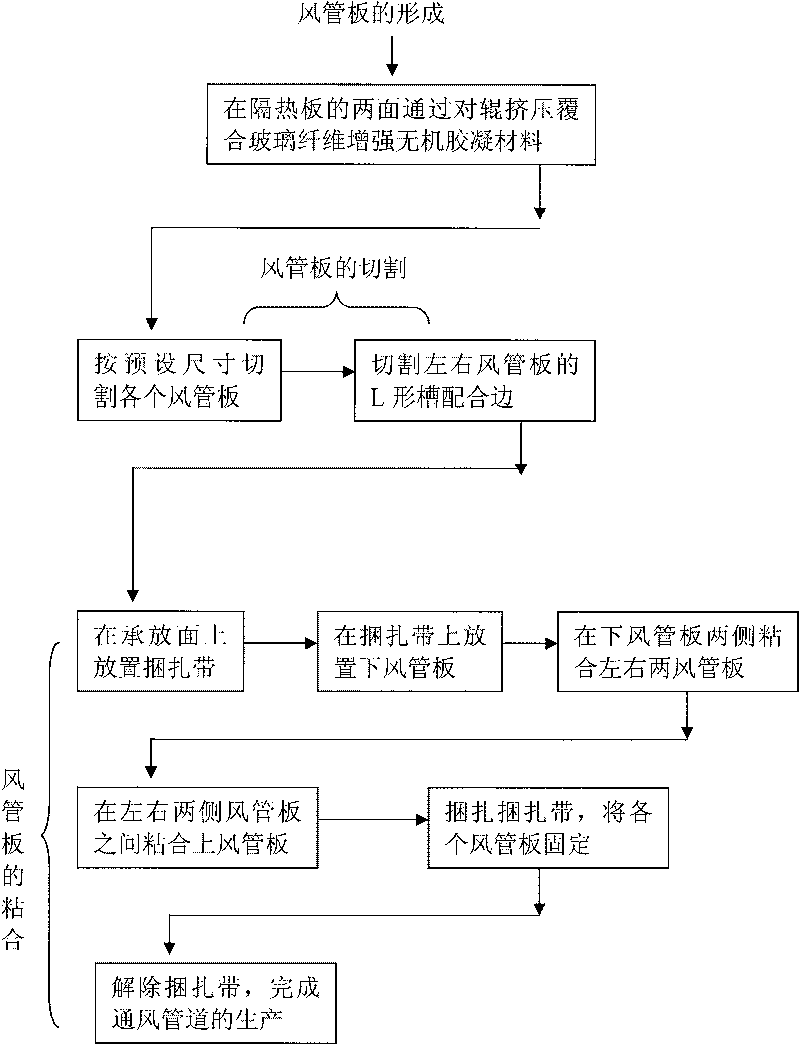

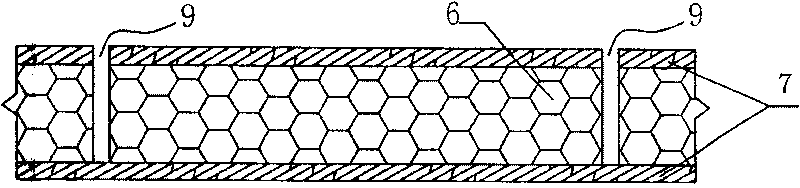

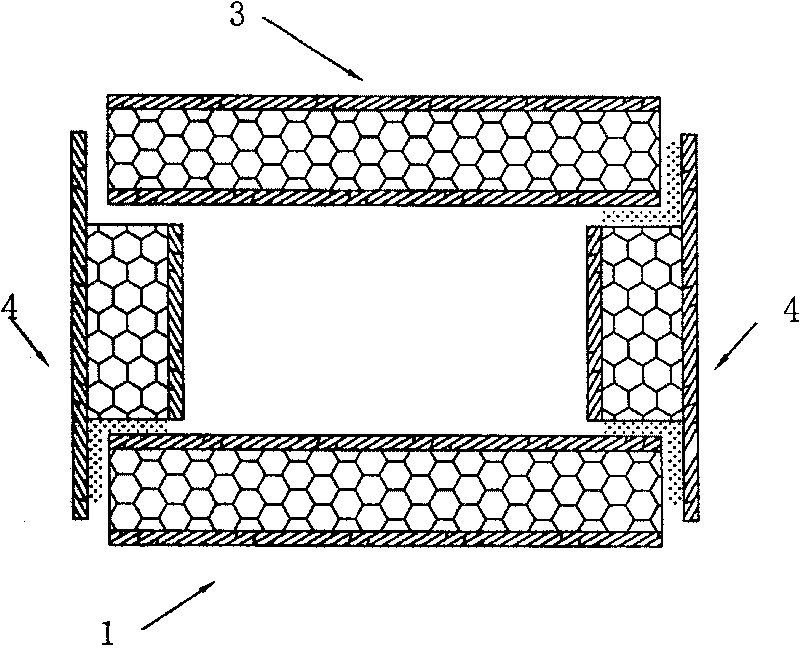

[0017] Embodiment: A kind of technique of combining air duct with strapping, as figure 1 As shown, the steps of the process are: Step 1, making the air duct plate; Step 2, cutting the air duct plate; Step 3, bonding the air duct. The bonding process of the air duct is as follows: place four straps 5 that are roughly evenly arranged on the bearing surface, and place the downwind duct plate 1 flat on the straps 5; then glue the left and right air duct plates to the downwind Both sides of the tube plate (the bonding edge of the left and right air duct plates are coated with adhesive in advance), and then the upper air duct plate 3 is glued between the two air duct plates (the lower air duct plate 1 and the upper air duct plate 1 The end of the tube plate 3 is misplaced with the left and right air tube plates 4, such as Figure 4 shown); tie the strapping 5 along the transverse direction of each air duct plate; after the adhesive is cured, remove the strapping 5.

[0018] The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com