Electret polarizing method

A technology of electret and polarity, applied in the direction of electret, electret electrostatic transducer, sensor, etc., to achieve the effect of simple method and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

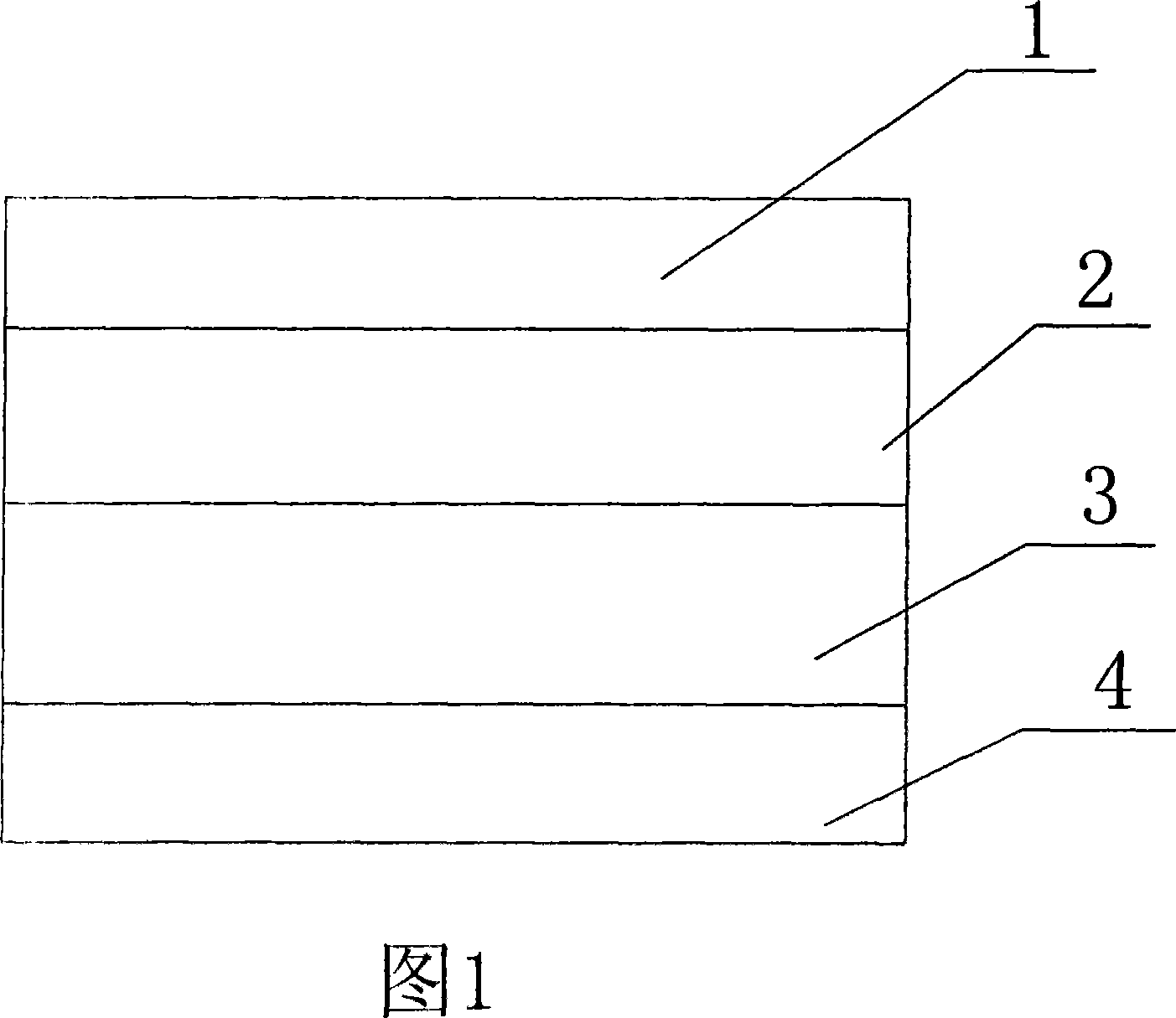

[0030] Embodiment 1 Referring to Fig. 1, the electret material of this embodiment adopts SiO 2 Film, polar polymer film using polyvinylidene fluoride.

[0031] ①. First vapor-deposit the metal electrode 4 on the back of the electret material 3;

[0032] ②. A layer of polar polymer film 2 is covered on the front of the electret material 3;

[0033] ③, raising the temperature to melt the polar polymer film 2;

[0034] ④. Attach another metal electrode 1 on the melted polar polymer film 2;

[0035] ⑤. Under the condition of keeping the polar polymer film 2 melted, a polarizing electric field is applied between the two electrodes for injection, and the voltage of the polarizing electric field is controlled so that the material does not undergo electrical breakdown;

[0036] ⑥. Cool down to room temperature and remove the electric field.

[0037] The electret obtained in this embodiment has a stable electric field.

Embodiment 2

[0038] Embodiment 2 Referring to Fig. 1, the electret material of this embodiment is SiO 2 / Si 3 N 4 Double-layer film, polar polymer film using polyvinylidene fluoride.

[0039] ①. First vapor-deposit the metal electrode 4 on the back of the electret material 3;

[0040] ②. A layer of polar polymer film 2 is covered on the front of the electret material 3;

[0041] ③, raising the temperature to melt the polar polymer film 2;

[0042] ④. Attach another metal electrode 1 on the melted polar polymer film 2;

[0043] ⑤. Under the condition of keeping the polar polymer film 2 melted, a polarizing electric field is applied between the two electrodes for injection, and the voltage of the polarizing electric field is controlled so that the material does not break down;

[0044] ⑥. Cool down to room temperature and remove the electric field.

[0045] The electret obtained in this embodiment also has a stable electric field.

Embodiment 3

[0046] Embodiment 3 Referring to FIG. 1 , the electret material in this embodiment is polytetrafluoroethylene film, and the polar polymer film is polyvinylidene fluoride.

[0047] ①. First vapor-deposit the metal electrode 4 on the back of the electret material 3;

[0048] ②. A layer of polar polymer film 2 is covered on the front of the electret material 3;

[0049] ③, raising the temperature to melt the polar polymer film 2;

[0050] ④. Attach another metal electrode 1 on the melted polar polymer film 2;

[0051] ⑤. Under the condition of keeping the polar polymer film 2 melted, a polarizing electric field is applied between the two electrodes for injection, and the voltage of the polarizing electric field is controlled so that the material does not break down;

[0052] ⑥. Cool down to room temperature and remove the electric field.

[0053] The electret obtained in this embodiment also has a stable electric field.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com