Bipolar transistor with floating ring structure

A bipolar triode, floating ring technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as excessive electric field strength, and achieve the effects of slowing down aggregation, avoiding electric field strength, and high blocking voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

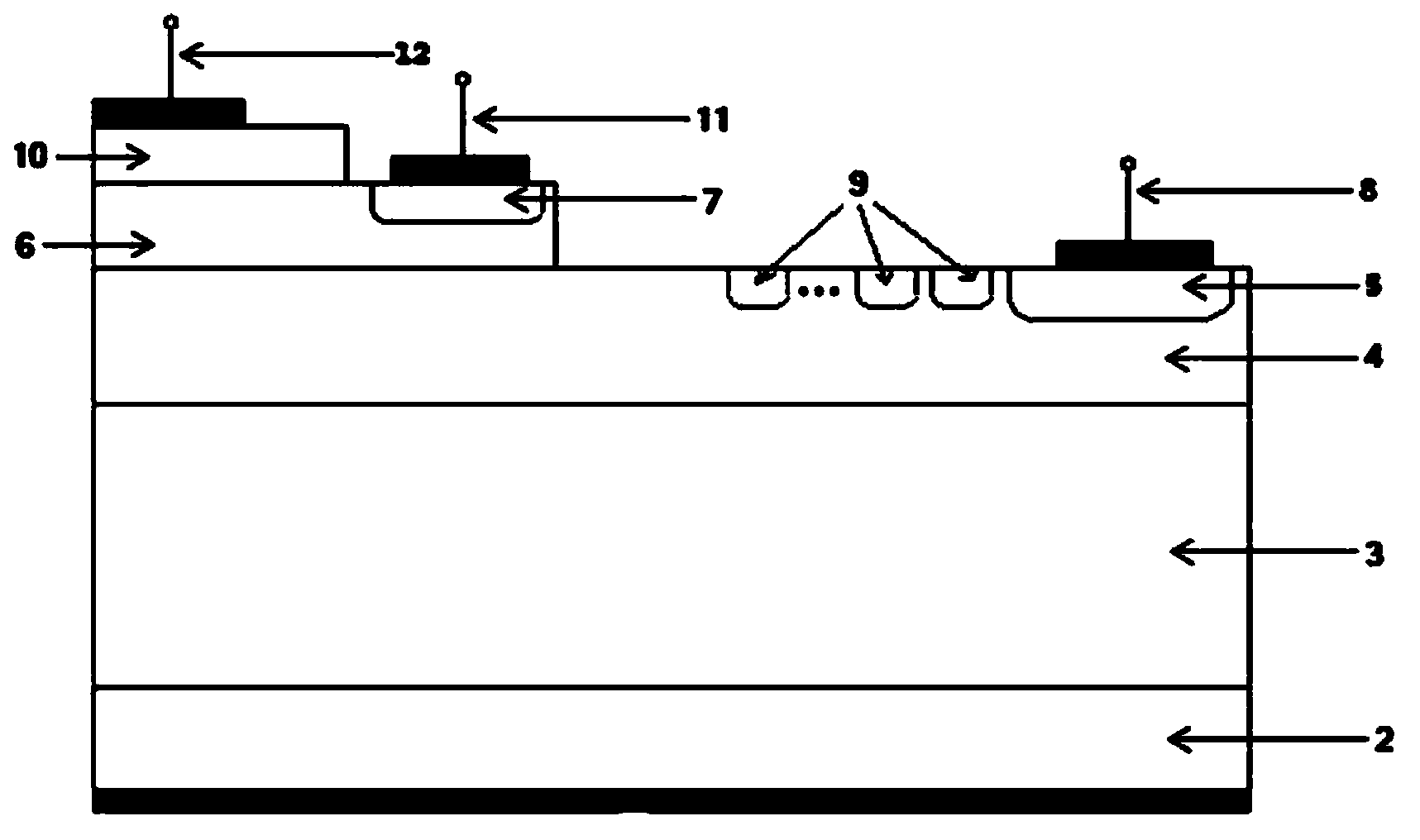

[0025] The structure of the bipolar triode with floating ring structure according to the present invention is as follows figure 1 As shown, the bipolar transistor here is an NPN lateral bipolar transistor (LBJT), which includes a substrate 2, a buffer zone 3, a collector region 4, a base region 6, and an emitter region 10 from bottom to top. Ohmic contact regions 7 and 5 are respectively formed at the boundaries of the base region 6 and the collector region 4, the emitter 12 is located on the emitter region 10, and the collector electrode 8 is located on the ohmic contact region 5 of the collector region 4 Above, the base 11 is located above the ohmic contact region 7 of the base region 6 . In this embodiment, the substrate 2 is P + Silicon carbide substrate, the buffer layer 3 on the upper layer is a silicon carbide epitaxial layer, and then the collector region 4 on the upper layer forms an ohmic contact region 5 in the collector region 4 by ion implantation, in the collect...

Embodiment 2

[0027] On the basis of Embodiment 1, the number of floating rings can be 1, 10, 40, 50, or 100, and generally 1-100 can be selected according to needs. In this embodiment, the number of the floating rings is 40, and the number here is set according to the material and size of the bipolar transistor. In order to ensure the gentle effect of the floating ring on the electric field of the ohmic contact area of the collector area, the setting distance between the floating ring and the ohmic contact area of the collector area is 0.5um, and the floating ring It is an annular floating region formed by ion implantation and annealing in the drift region of the collector region. The ions here can be selected from boron ions and aluminum ions. In this embodiment, boron ions are selected. In order to improve the breakdown resistance of the entire surface of the collector region, a plurality of floating rings may also be arranged on the surface of the collector region, and floating ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com