Method and system for monitoring intelligent material allocation

An intelligent material and monitoring system technology, applied in the field of garment processing, can solve the problems of barcode technology limitation performance, slow barcode recognition speed, poor anti-interference ability, etc., and achieve the effect of realizing informatization and fast and accurate identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

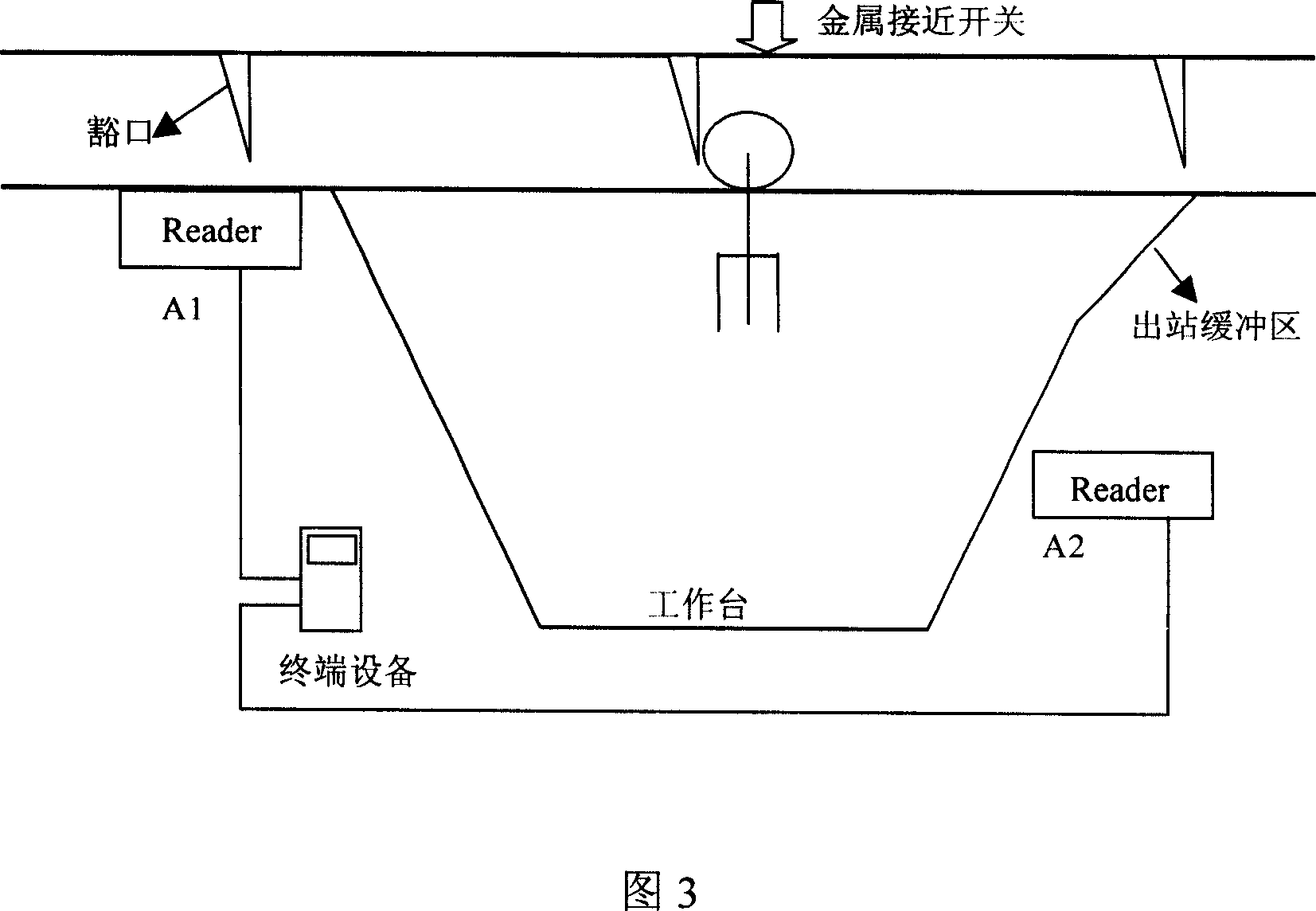

[0034] Referring to Figure 3, the settings of each workstation are explained as follows:

[0035] 1. A terminal device that communicates with the host computer through the CAN bus.

[0036] 2. Two RFID card readers (Reader), one is placed before the entrance, and the other is placed before the exit buffer. The signals of the two card readers are sent to the host computer in a defined frame format through the terminal equipment.

[0037] 3. PLC (Programmable Logic Controller, Programmable Logic Controller), receives the control signal of the host computer through the RS485 interface; receives the pulse signal of the proximity switch; outputs the switch signal to control the action of the mechanical equipment.

[0038] 4. An inductive proximity switch is placed at a certain position before the exit (the specific position parameters need to be determined according to the site settings) to detect metal objects (hangers in this system), when a metal object enters the detection ran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com