Contact network system of high-speed electric railway

A technology for electrified railways and catenary, applied in overhead lines and other directions, can solve problems such as inability to meet high-speed operation requirements, and achieve the effects of overcoming tooth defects, improving performance, and increasing sliding load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

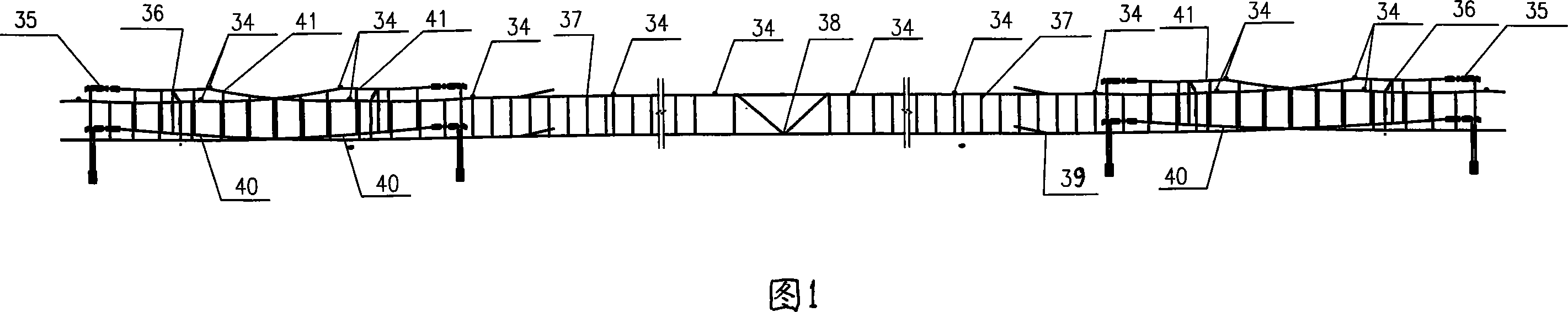

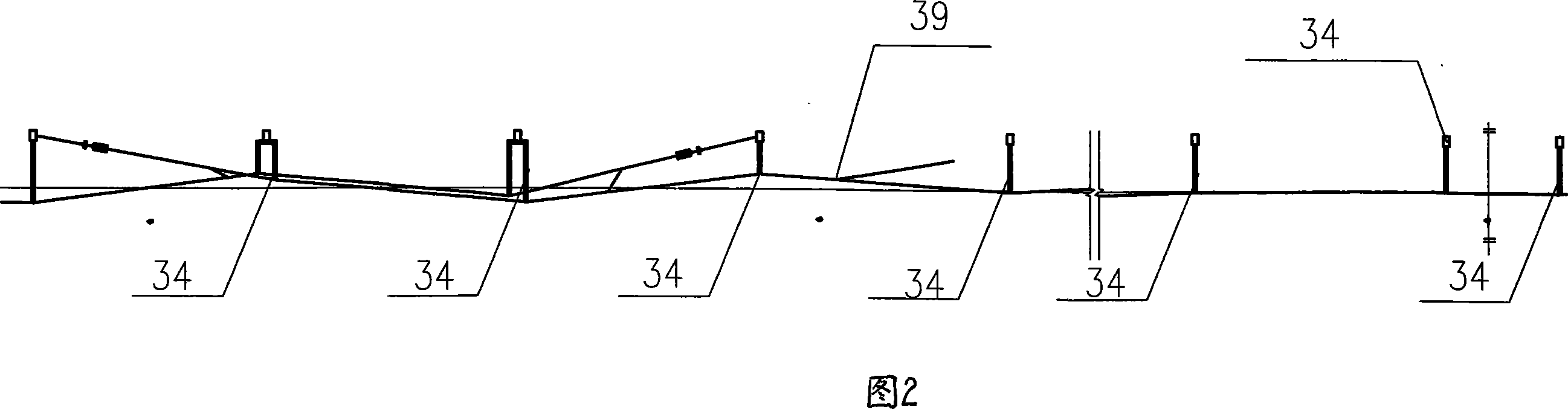

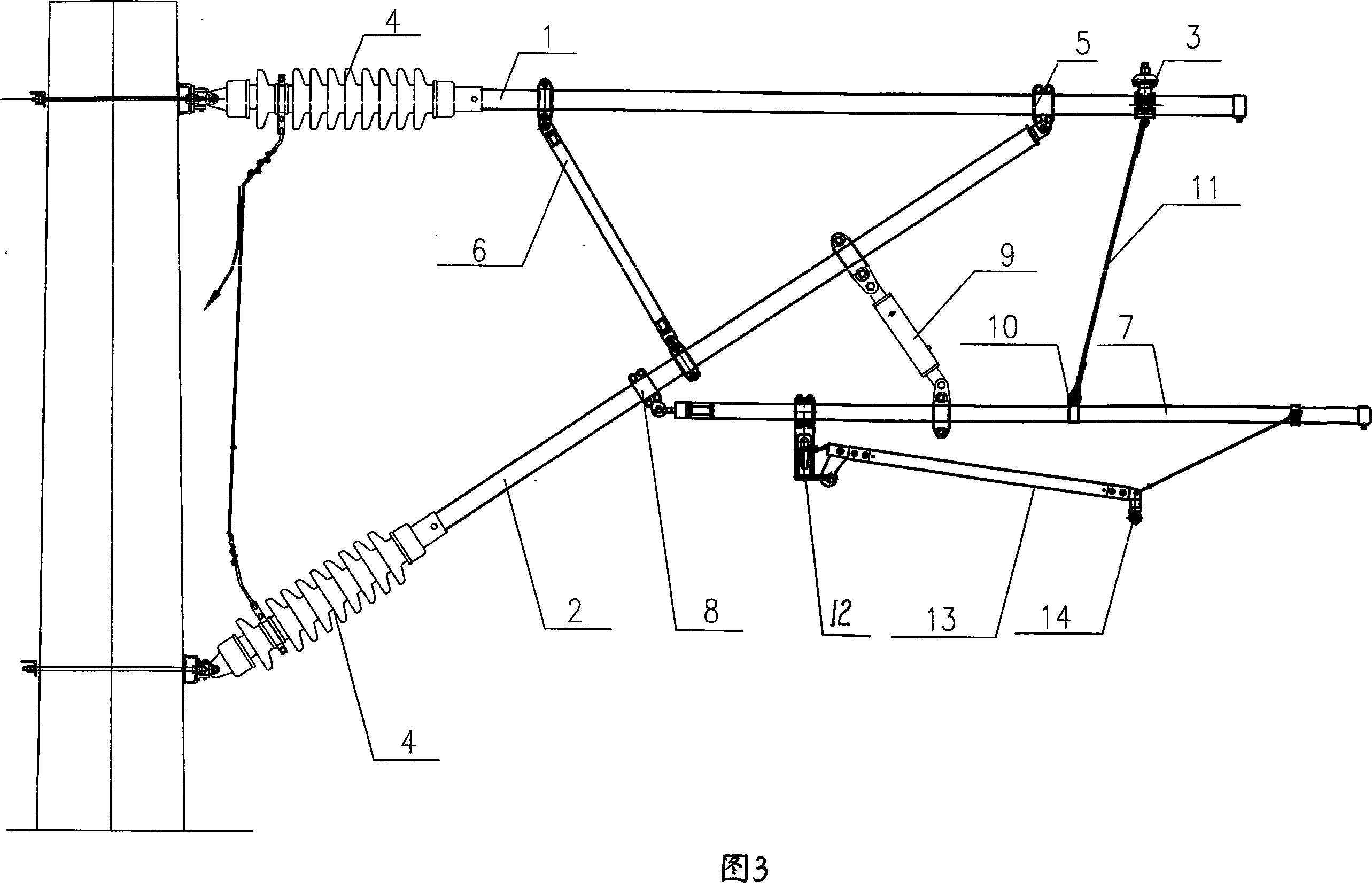

[0056] An embodiment of the present invention is described in conjunction with accompanying drawings 1, 2, 3, 4, 5, 6, 7, 8, 9, 10.

[0057] A high-speed electrified railway catenary system is formed by interconnecting multiple anchor sections. Each anchor section includes a wrist arm positioning device 34 , an anchor compensating device 35 , an electrical connection device 36 , a string hanging device 37 , a central anchoring device 38 and a wire fork 39 . The lower anchor compensation device 35 is arranged at both ends of each anchor section, the central anchor knot device 38 is arranged at the middle of each anchor section, and the electrical connection device 36 is arranged on the inner side of the lower anchor compensation device 35, between the lower anchor compensation device 35 and the center. Between the anchoring devices 38 , each anchor segment is provided with a plurality of arm positioning devices 34 and string hanging devices 37 . The distance between two adjace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com