Manufacture of bridging crane main beam

An overhead crane and manufacturing process technology, applied in the directions of load hanging elements, transportation and packaging, support structures, etc., can solve the problems of lower deflection of the main beam of the crane, lowering of the lifting weight, and gnawing of rails by carts, so as to increase the cutting capacity. The effect of area, low cost and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

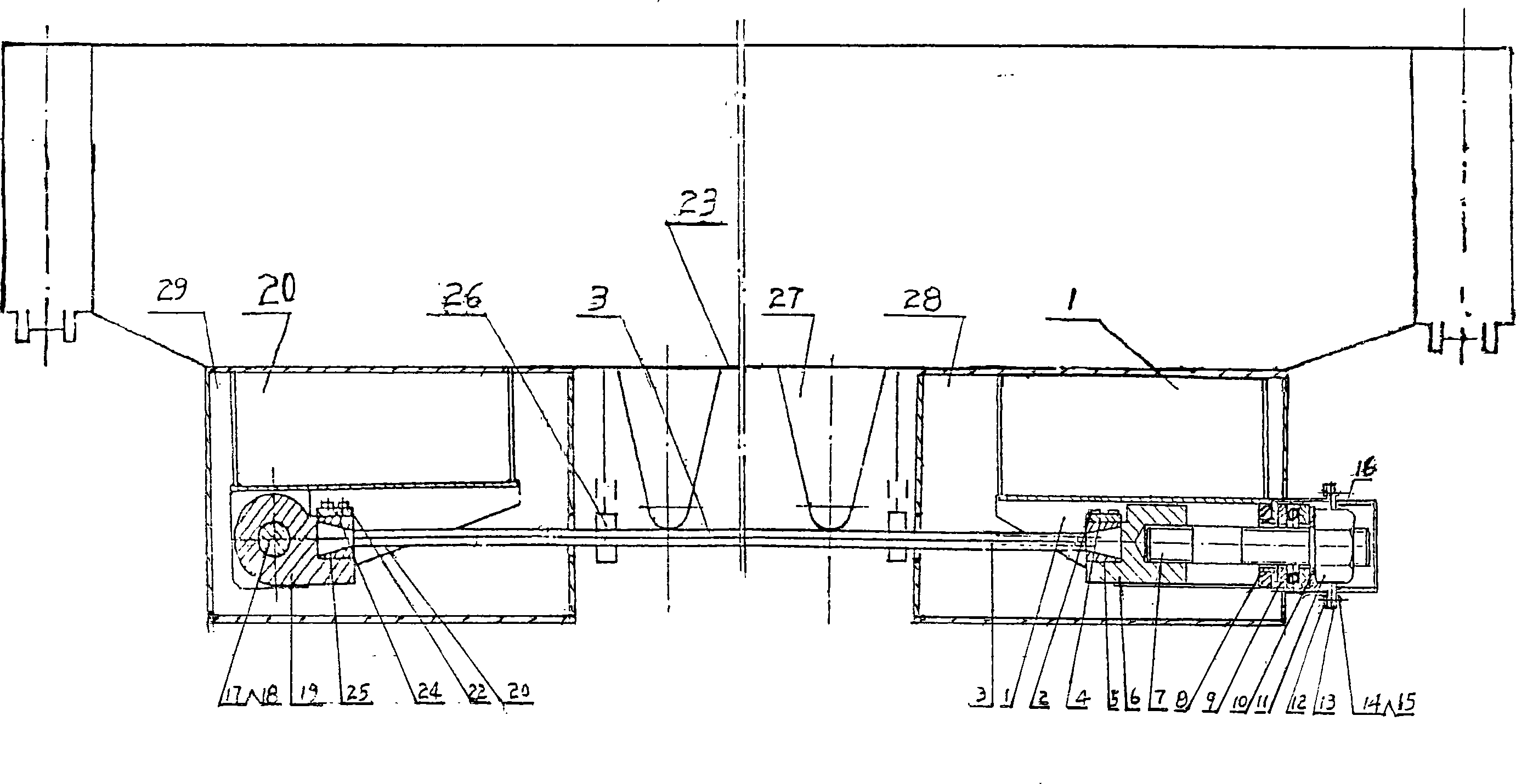

[0010] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0011] The first step: preparation process:

[0012] Lift the crane main girder that has been completed according to the main beam manufacturing drawings and processes of the bridge crane, and position the lower cover plate at a height of 1.4-1.6 meters from the ground. Support the main girder and end girder with a supporting frame or pads to make them fall stably.

[0013] The second step: welding process:

[0014] Place the tensioner box 1 in the additional rectangular parallelepiped tensioner transition box 28, weld it into a whole piece, set some reinforcement plates as required, and then weld the whole piece to one end of the lower cover plate of the main beam 23, Rope head is connected hinge support 20 and is placed in the cuboid connection hinge support transition box 29 of setting up again, is welded into whole, and is welded on the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com