Float glass lehr air-cooled device

A technology of air-cooling device and float glass, which is applied in the field of air-cooling device to achieve the effects of simplified pipeline system, convenient maintenance and superior control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

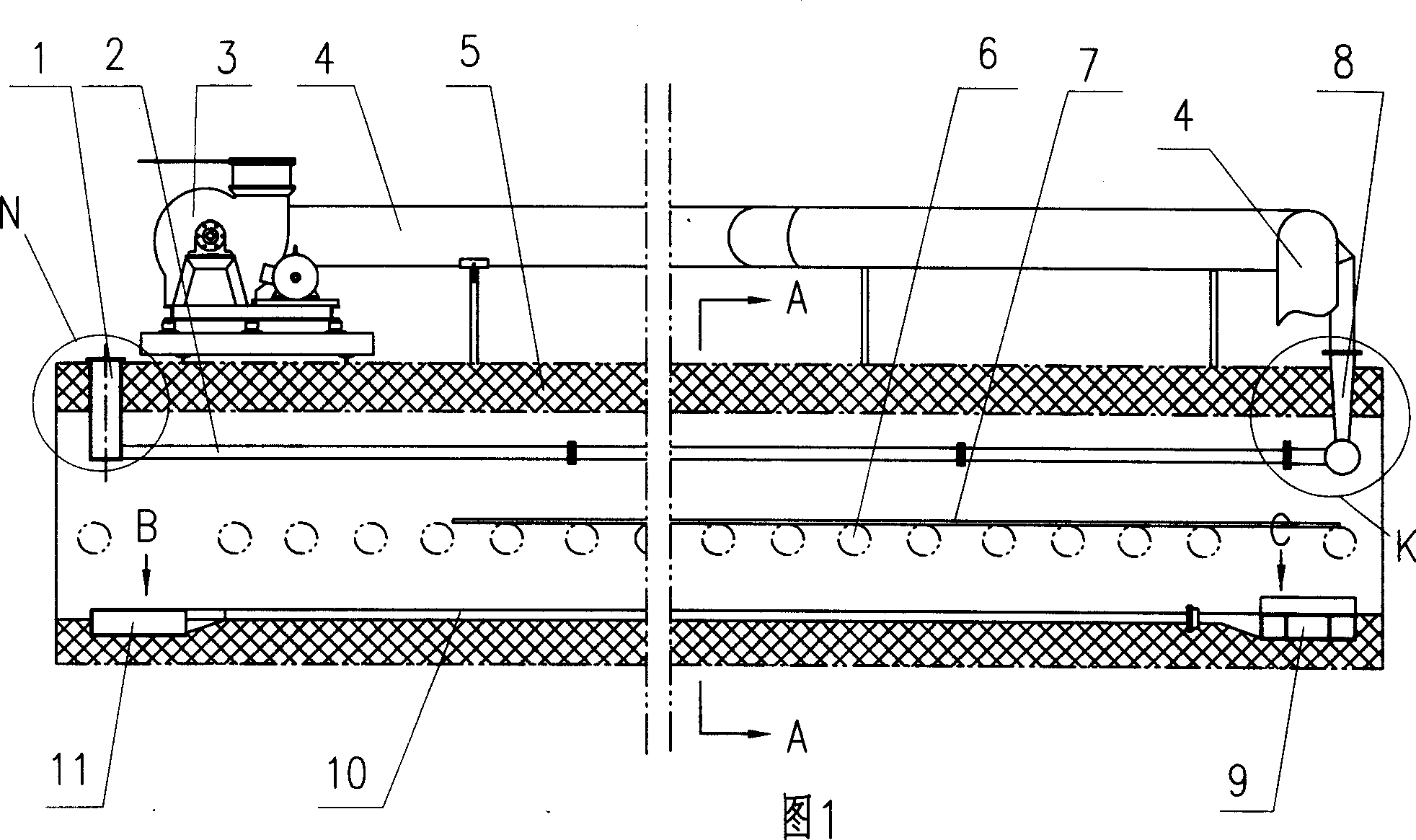

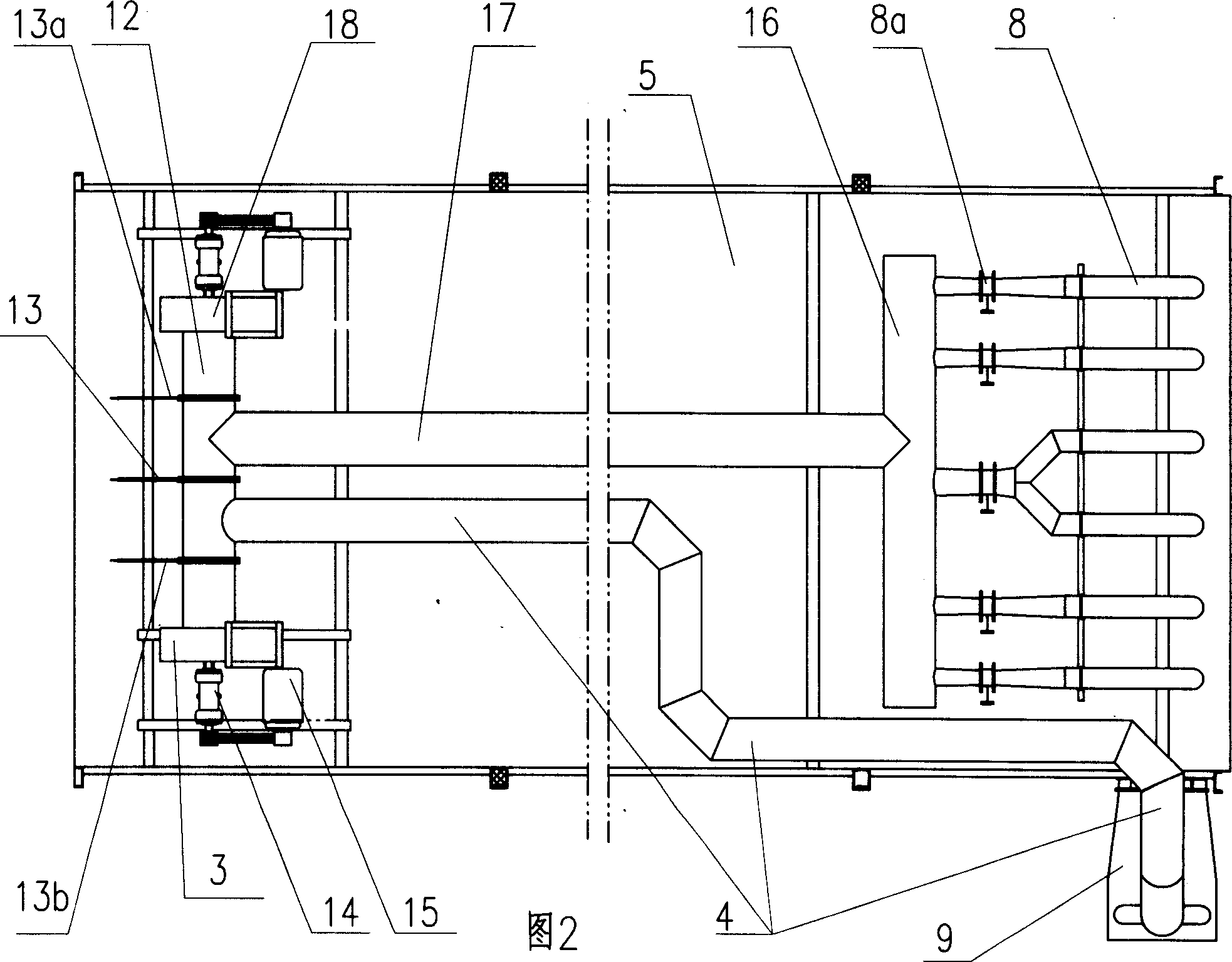

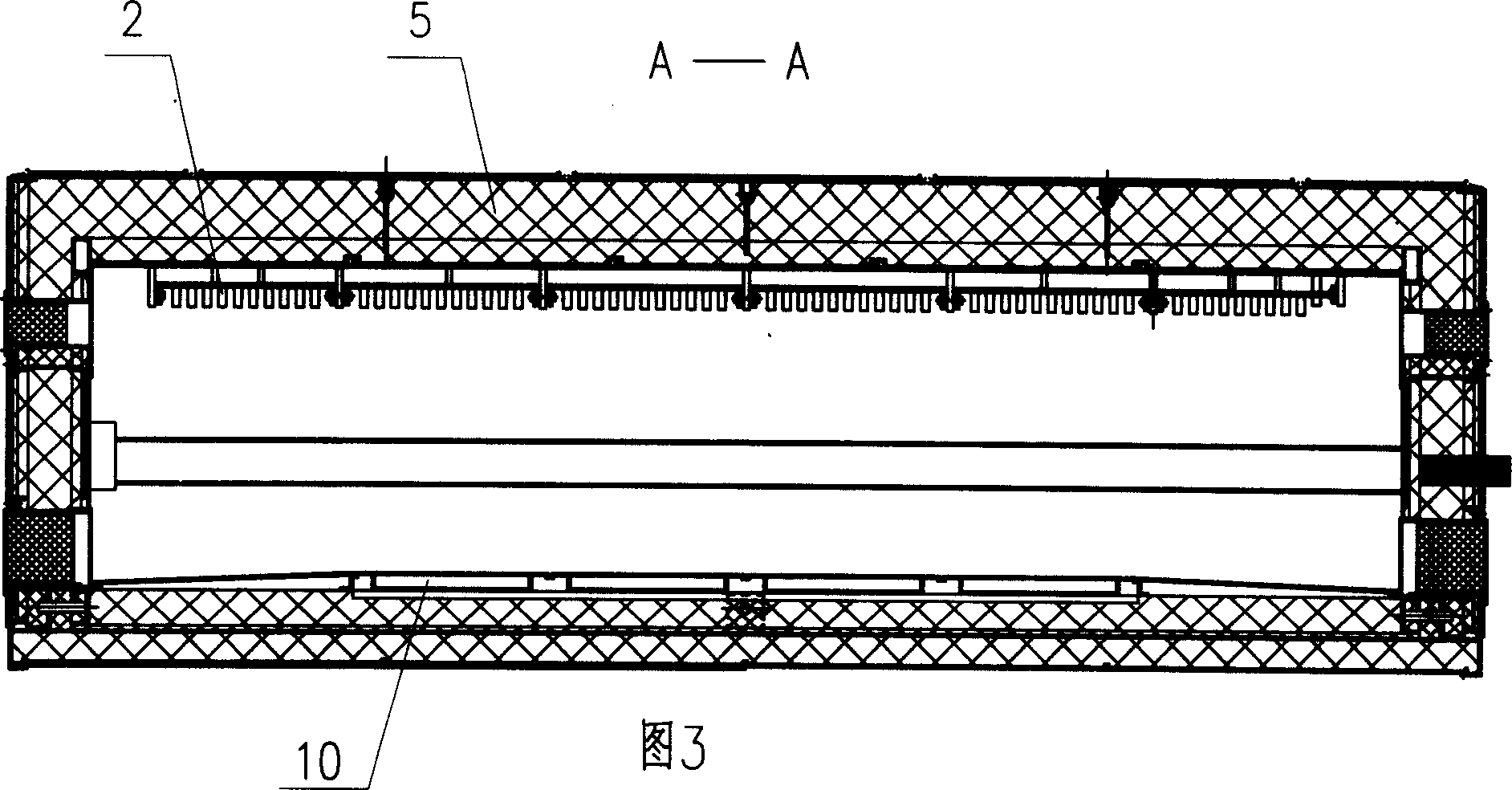

[0024] Specific embodiments: as shown in Figure 1, the annealing kiln 5 is an all-steel structure, and an insulating material is provided in its interlayer, and a group of rollers 6 are arranged inside the annealing kiln 5 to form a glass roller table, and the annealed glass 7 is placed on the glass roller. Move right on the road. On the upper part of the annealing kiln 5, there are 4-6 groups of small air pipes 2, and the left end of each group of small air pipes 2 is respectively connected with the upper wind collecting pipe 1 arranged on the kiln body. The specific structure is shown in Fig. 7 and Fig. 8 , a total of 6 groups of small air ducts, the number of each group of small air ducts 2 is 6-12, and each group of small air ducts 2 is connected to the upwind summarizing pipe 1 after summarizing on the left side, and the top of the upwind summarizing pipe 1 is provided with a filter 1a to prevent debris from entering. Returning to Fig. 1, the other end of each group of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com