Method and device for producing single yarn on operation unit of rotor spinning machine

A rotor spinning machine and operating unit technology, which is applied in the field of single yarn spinning, can solve the problems of affecting the length of the tail yarn, the quality of the joint, and the inability to control the speed of yarn drafting or winding, etc., so as to improve the synchronization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

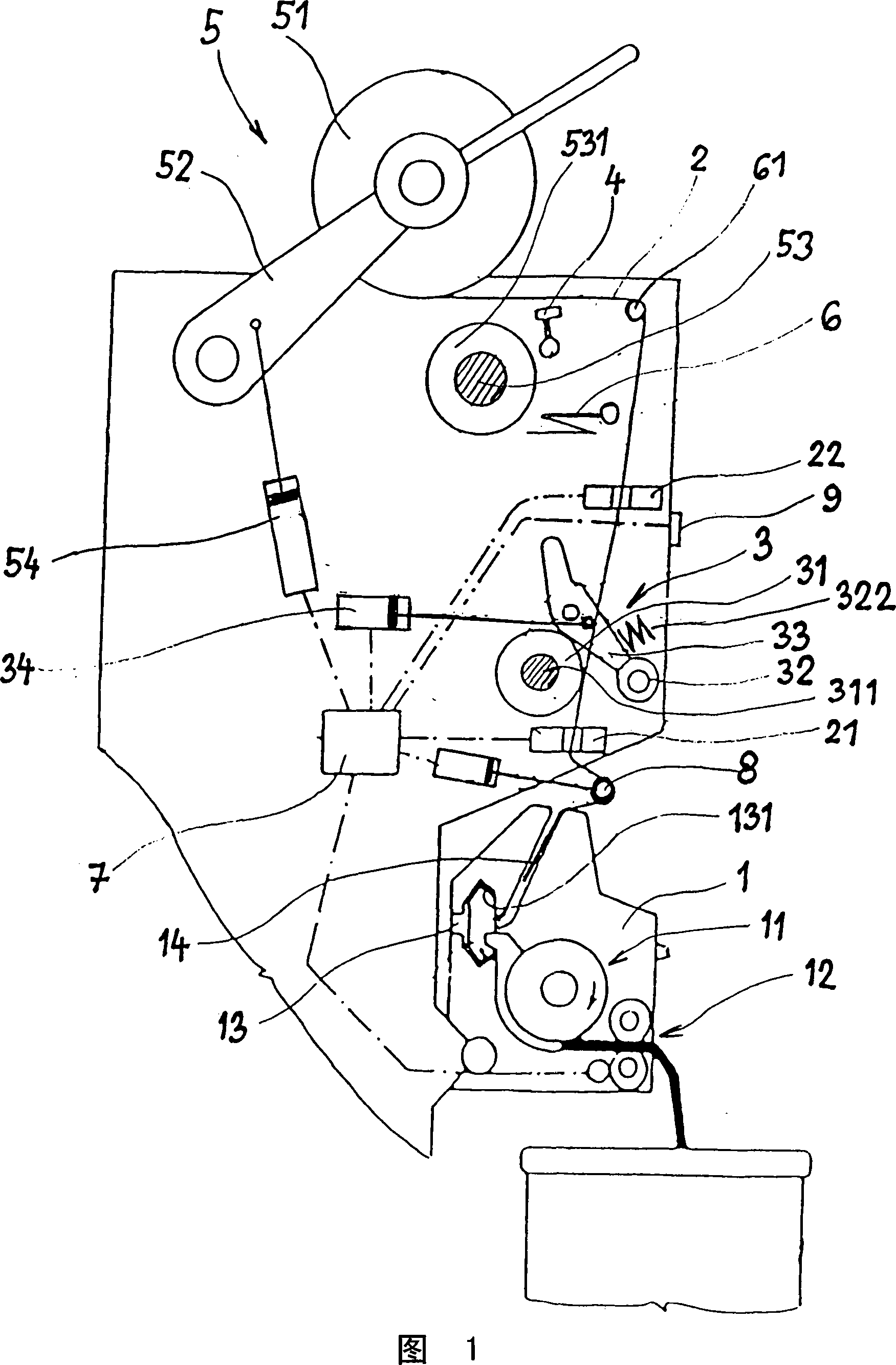

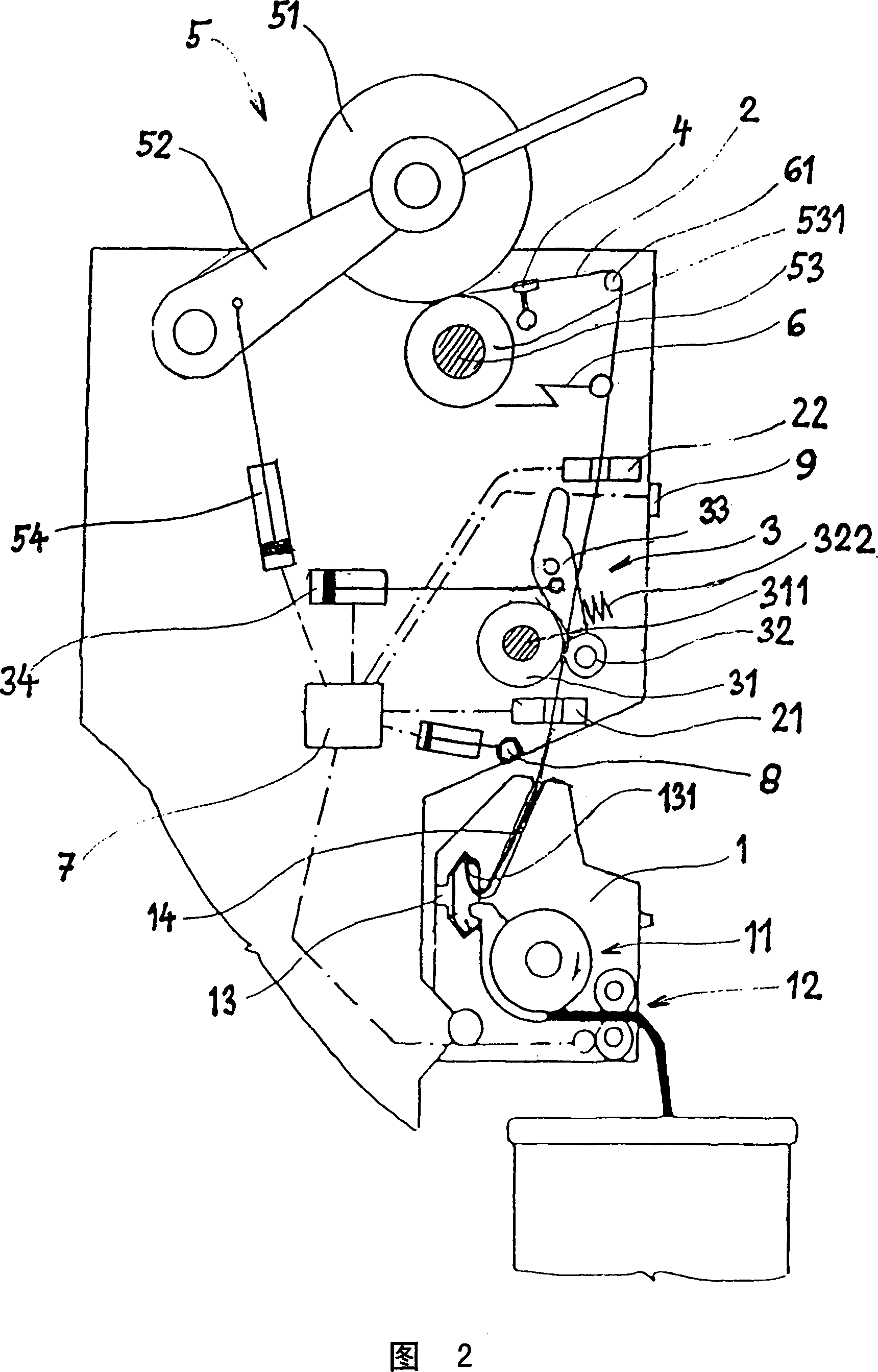

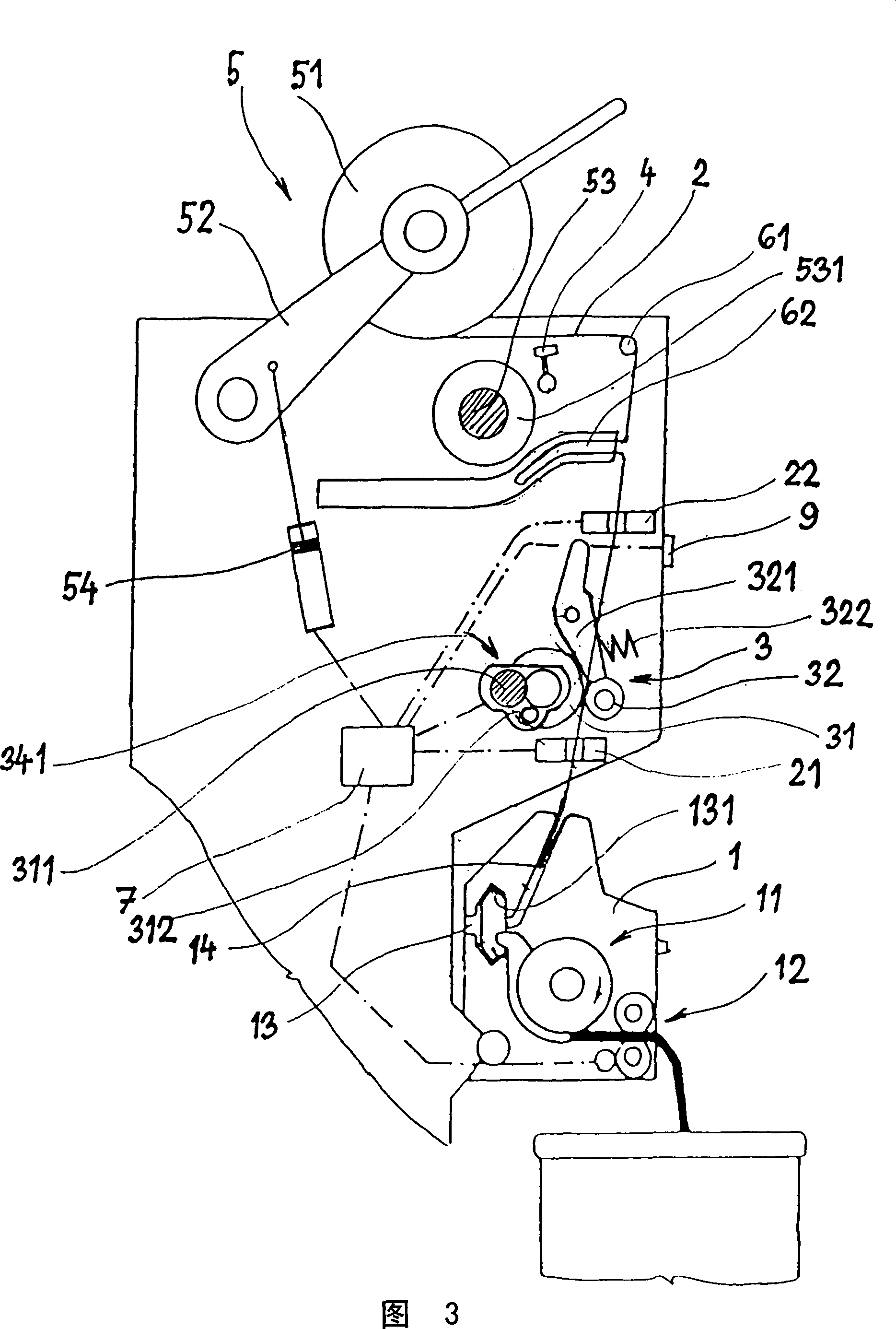

[0023] A rotor spinning machine comprises a number of operating units arranged side by side, each operating unit representing a combined device which independently produces a yarn from a sliver of textile fibers and winds the produced yarn onto a bobbin.

[0024] Each operating unit includes a spinner 1 whose main components are a sliver feeding device 12 , a carding device 11 , a spinning rotor 13 with a condensation groove 131 and a yarn delivery tube 14 .

[0025]A yarn quality and yarn presence sensor 21 and a drafting device 3 thereon are arranged above the spinning box 1 . In the illustrated embodiment, above the drafting device 3 there is a sensor 22 for detecting the presence of yarn, a sensor for detecting the quality and presence of yarn may be arranged. Arranged above the sensor 22 are a yarn distribution device 4 and a yarn winding device 5 in which the final winding bobbin 51 is mounted.

[0026] A first embodiment of the invention is shown in FIGS. 1 and 2 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com