Multiple tubular pile type bar-free gas-production oil-production method and device

A technology of oil production equipment and composite pipe, which is applied in the direction of production fluid, earthwork drilling, wellbore/well parts, etc., can solve the problems of frequent operation, difficult operation, cavitation, etc., and achieve the solution of eccentric wear and production cost of oil and water wells Low, avoid low-efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

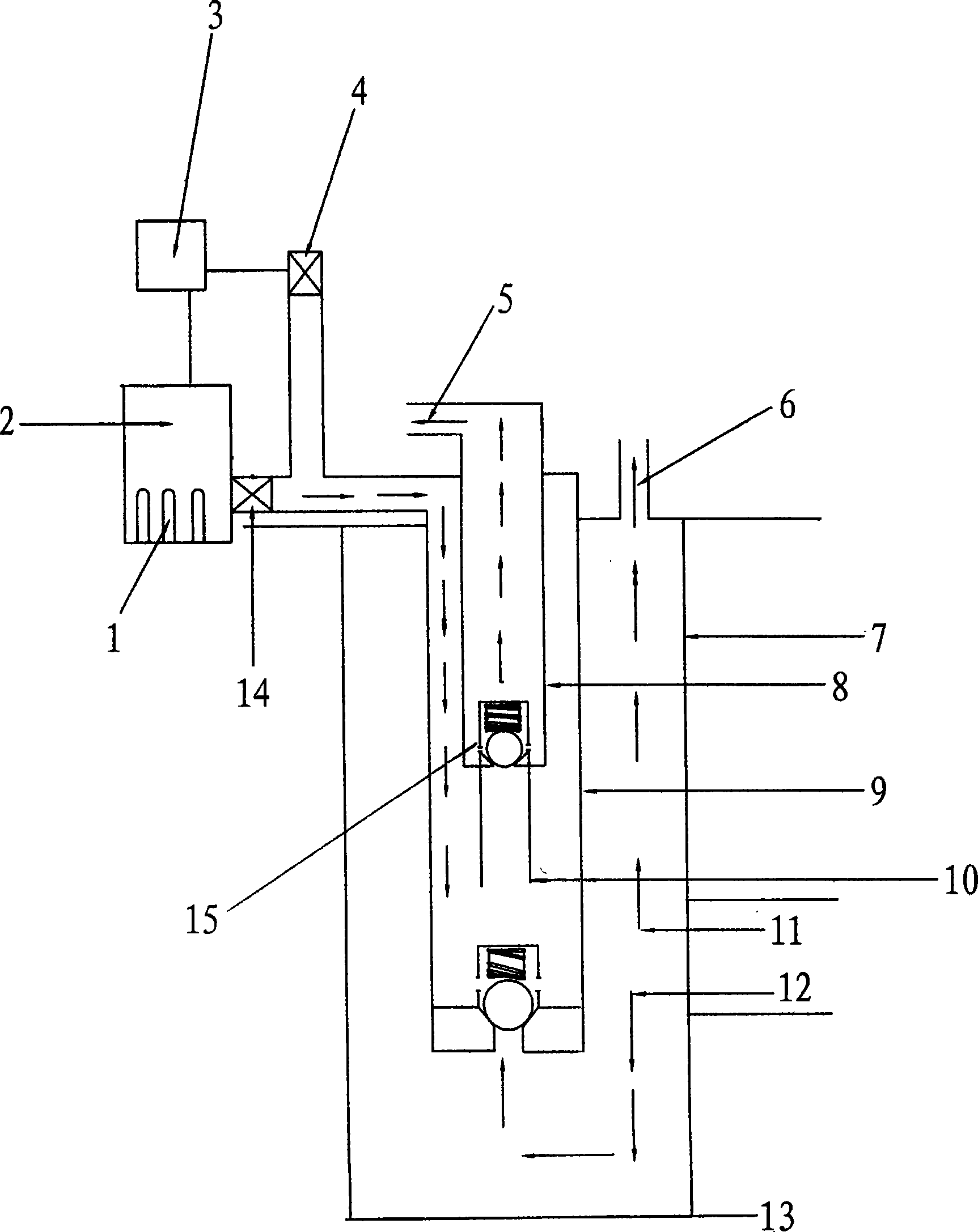

[0017] A composite string-type rodless gas recovery and oil recovery method, including gas recovery and oil recovery from deep wells, gas recovery and oil recovery from deep wells is carried out by using a gas injection device and a composite tube string for oil recovery and water recovery, that is to say, from the wellhead through injection The gas device injects gas into the composite pipe string for oil production and water production in the well, and discharges the accumulated water in the well from the composite pipe string for oil production and water production. The natural gas in the well is produced from the annulus of the oil casing. Extracted from.

[0018] The gas injection of the wellhead gas injection device into the oil production and water production composite pipe string in the well is an annular space injection between the outer oil pipe and the inner oil pipe of the self-production oil and water production composite pipe string for intermittent gas injection....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com