Combined process for cleaning infectant on the surface of cardinal plate

A technology for substrate surface and pollutants, applied in cleaning methods and utensils, cleaning methods using gas flow, chemical instruments and methods, etc., can solve problems such as inability to effectively remove particles, and achieve the effect of reducing equipment costs and improving cleaning effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

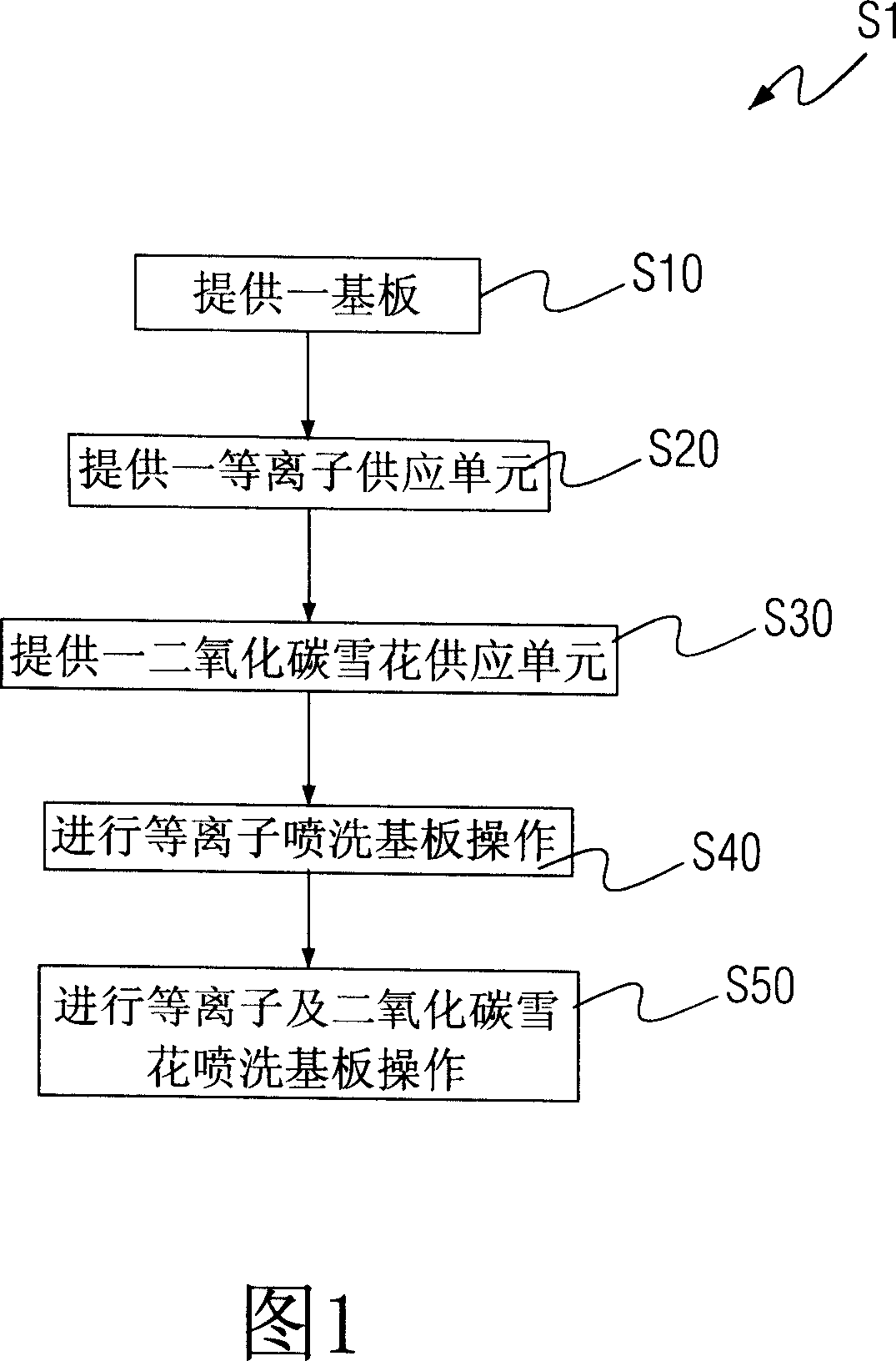

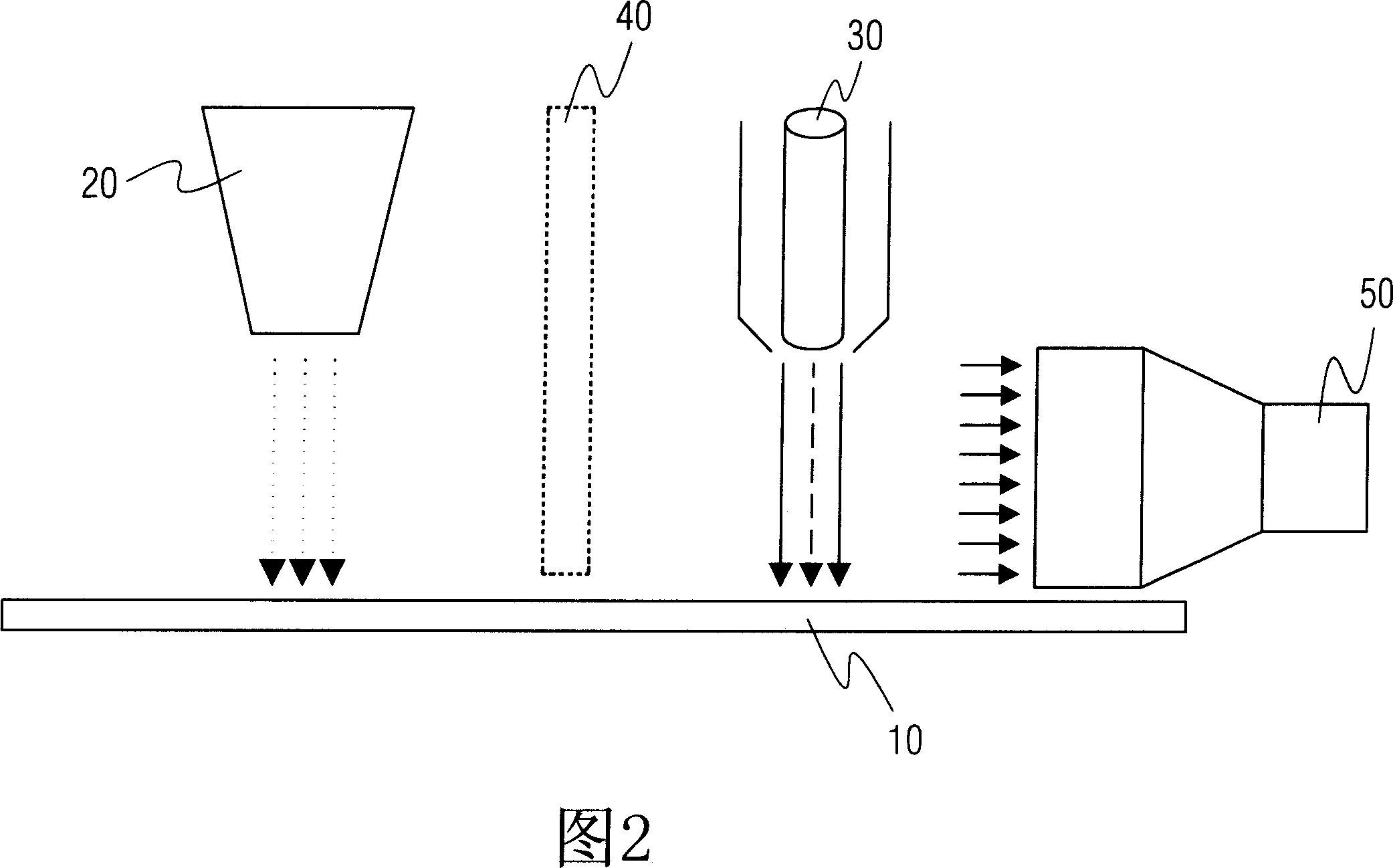

[0027] As shown in FIG. 1 , a method of the present invention for cleaning surface pollutants of a composite substrate, the method S1 of the composite cleaning substrate surface pollutants includes providing a substrate (step S10), providing a plasma supply unit ( Step S20 ), providing a carbon dioxide snowflake supply unit (step S30 ), performing plasma spraying operation on the substrate (step S40 ), and performing plasma and carbon dioxide snowflake spraying operation on the substrate (step S50 ).

[0028] With reference to Fig. 1 and Fig. 2, a kind of method of the present invention is with the method S1 of the surface contamination of composite cleaning substrate, the method S1 of the surface contamination of this composite cleaning substrate, firstly provide a substrate (step S10), substrate 10 surface There are pollutants, and the substrate 10 can be moved, that is, the substrate 10 is arranged on a moving mechanism (not shown in the figure) to reach the substrate to mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com