Rotary tool for surface processing

A technology of rotary tool and surface machining, applied in metal processing, manufacturing tools, wheels with flexible working parts, etc., can solve the problems of difficult surface machining, limitations of rotary tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

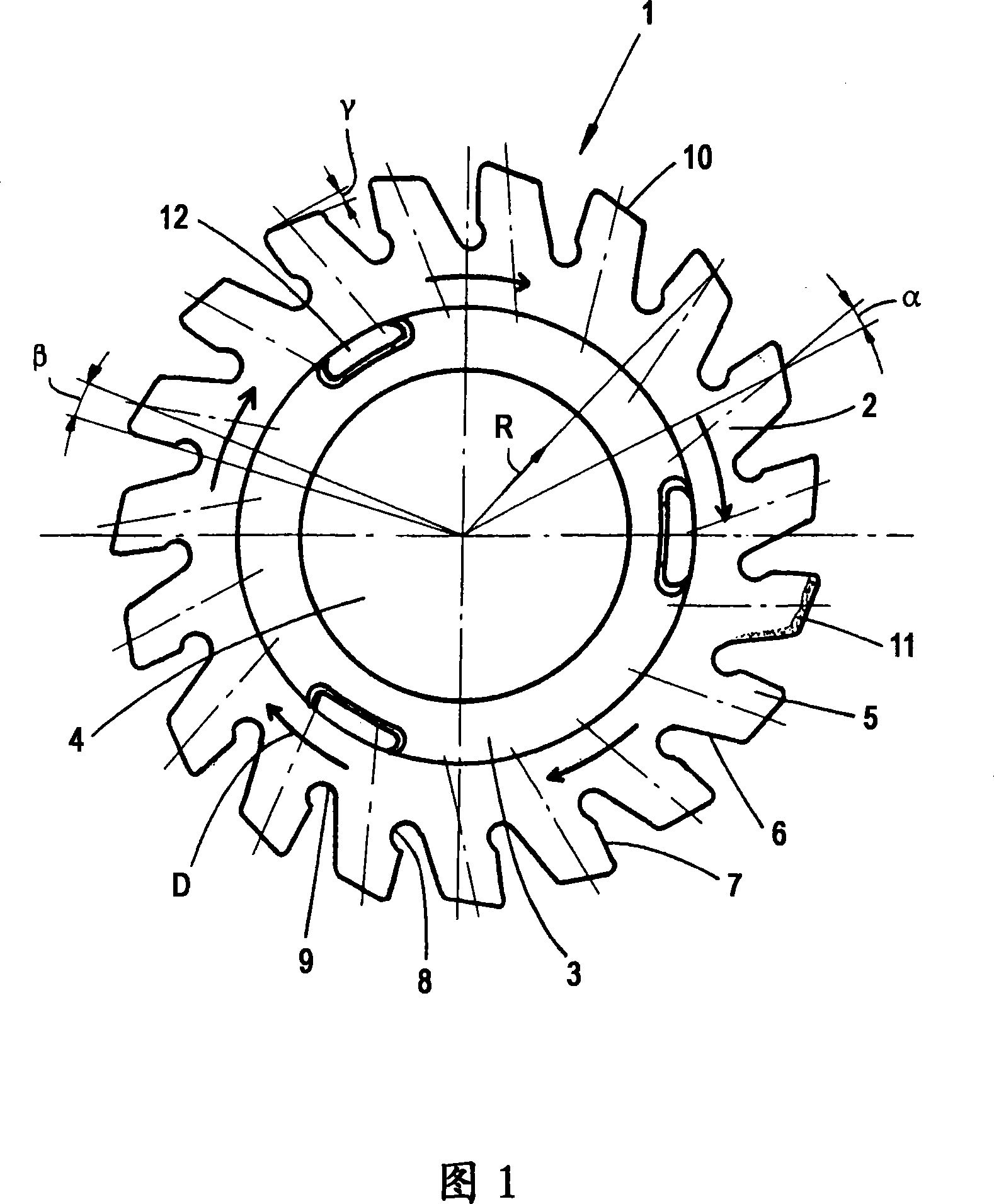

[0023] In the figure, the rotary tools for surface machining are shown in the embodiment as a disc 1 , an annular disc and a foil remover, respectively. Said disc 1 consists of rubber-elastic plastic, in this case polyurethane (PUR). However, it is also possible for only the outer ring 2 to be made of rubber-elastomeric plastic, while the inner ring 3 consists of thermoplastic rubber.

[0024] For machining purposes, the disk 1 has an outer ring 2 and an inner ring 3 for connection to a disk holder 4 that can be driven in rotation and is only shown. The outer ring 2 of the disc 1 has elastically bendable processing teeth 5, which are distributed on the circumference of the disc 1 and stand upright away from the circumference, and the processing teeth 5 are arranged on the outer ring 2 at equal intervals from each other. .

[0025] Each machining tooth 5 has a front machining edge 6 and a rear machining edge 7 . Obviously, the front machining edge 6 and the rear machining ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com