Modified daubing brick

A lime-sand brick and modification technology, which is applied in the directions of climate sustainability, building components, sustainable waste treatment, etc., can solve the problems of limiting the application range of lime-sand bricks, difficult to adapt to building requirements, etc., and achieves expanded use and low cost. , the effect of increasing the porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

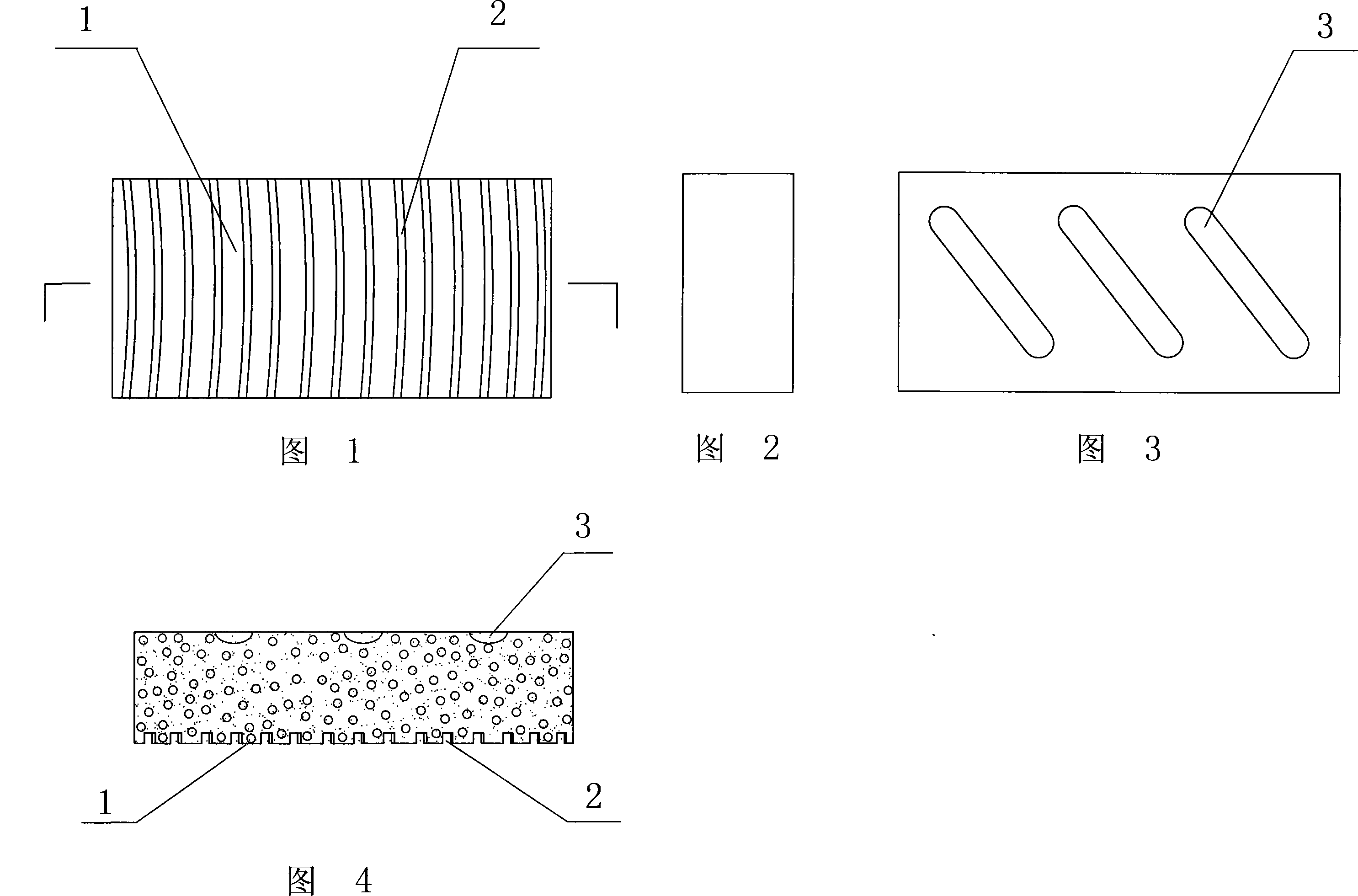

[0018] The first embodiment: take 80% of sand, 10% of quicklime, and 3% of expanded perlite particles, add water and stir evenly, digest for 4 hours, and press it into a brick of 240 × 115 × 53mm with a brick press, and the brick will pass through during the process. Use multiple scribe scratchers to draw multiple scratches with a depth of 0.5-2mm on the surface, and then send them into the autoclave at a temperature of 174°C and a steam pressure of 8kg / cm 2 , autoclave for 6 hours, and then keep warm for 8 hours to obtain a bulk density of 1650kg / m 3 , finished bricks with compressive strength above 15mpa.

[0019] The second embodiment: take 85% of sand, 10% of quicklime, and 5% of shale ceramsite, add water to fully stir, and then digest for 4 hours, press it into a 240×115×53mm adobe with a brick press, and send it into the autoclave , temperature 180°C, steam pressure 8.5kg / cm 2 , autoclaved for 9 hours, and then heat-preserved for 10 hours, you can get a bulk density o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com