Oxide sulfide fluorescent powder for white light-emitting diode and preparation method thereof

A light-emitting diode and oxysulfide technology, applied in the field of fluorescent materials, can solve the problems of large light decay, poor stability, easy moisture absorption and deliquescence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

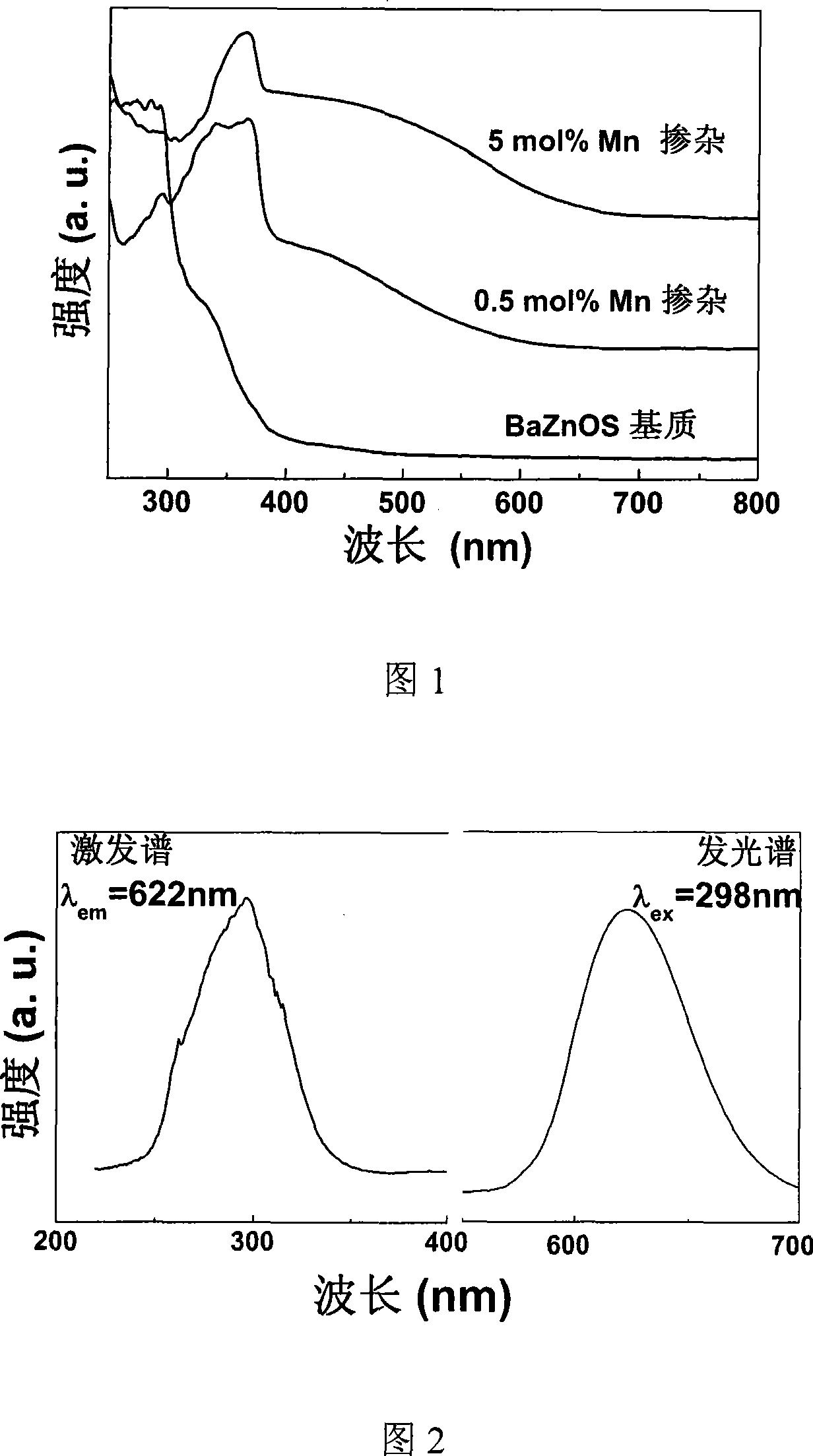

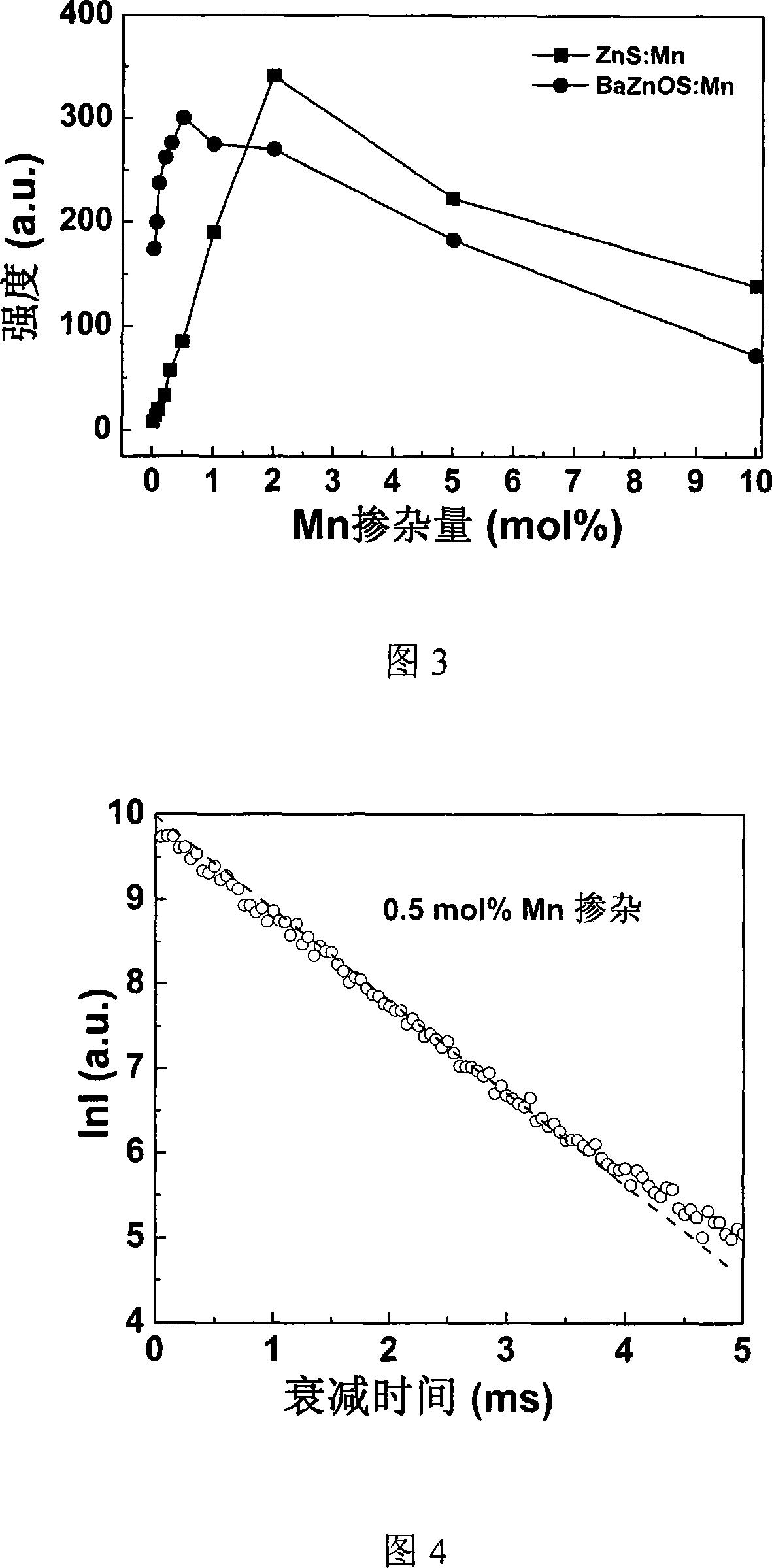

[0041] The raw materials ZnO, BaS, MnO according to BaZn 0.9998 mn 0.0002 The stoichiometric ratio of OS was weighed, mixed evenly in a device filled with nitrogen or argon, filled with quartz glass, and vacuumed (less than 10-2 Pa) and sealed with a hydrogen-oxygen flame, the glass tube containing the mixture was slowly heated to 830°C and kept for 24 hours, and then slowly cooled to room temperature. The same as before, finally made BaZnOS:Mn fluorescent material. Zn 0.9998 mn 0.0002 S was prepared by the same method as a reference for luminous intensity comparison. The test results are shown in Figure 3.

Embodiment 2

[0043] The raw materials ZnO, BaS, MnO according to BaZn 0.9994 mn 0.0006 The stoichiometric ratio of OS was weighed, mixed evenly in a device filled with nitrogen or argon, put into a quartz glass tube, and vacuumed (less than 10 -2 Pa) and sealed with a hydrogen-oxygen flame, the glass tube containing the mixture was slowly heated to 830°C and kept for 24 hours, and then slowly cooled to room temperature. The same as before, finally made BaZnOS:Mn fluorescent material. Zn 0.9994 mn 0.0006 S was prepared by the same method as a reference for luminous intensity comparison. The test results are shown in Figure 3.

Embodiment 3

[0045] The raw materials ZnO, BaS, MnCO 3 According to BaZn 0.999 mn 0.001 The stoichiometric ratio of OS was weighed, mixed evenly in a device filled with nitrogen or argon, put into a quartz glass tube, and vacuumed (less than 10 -2 Pa) and sealed with a hydrogen-oxygen flame, the glass tube containing the mixture was slowly heated to 830°C and kept for 24 hours, and then slowly cooled to room temperature. The same as before, finally made BaZnOS:Mn fluorescent material. Zn 0.999 mn 0.001 S was prepared by the same method as a reference for luminous intensity comparison. The test results are shown in Figure 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com