Switch reluctance motor direct servo driven novel pump controlled type hydraulic power transmission system

A switched reluctance, servo drive technology, applied in transmission, fluid transmission, mechanical equipment, etc., can solve the problem of complex oil requirements system, and achieve the effect of high precision, high reliability and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

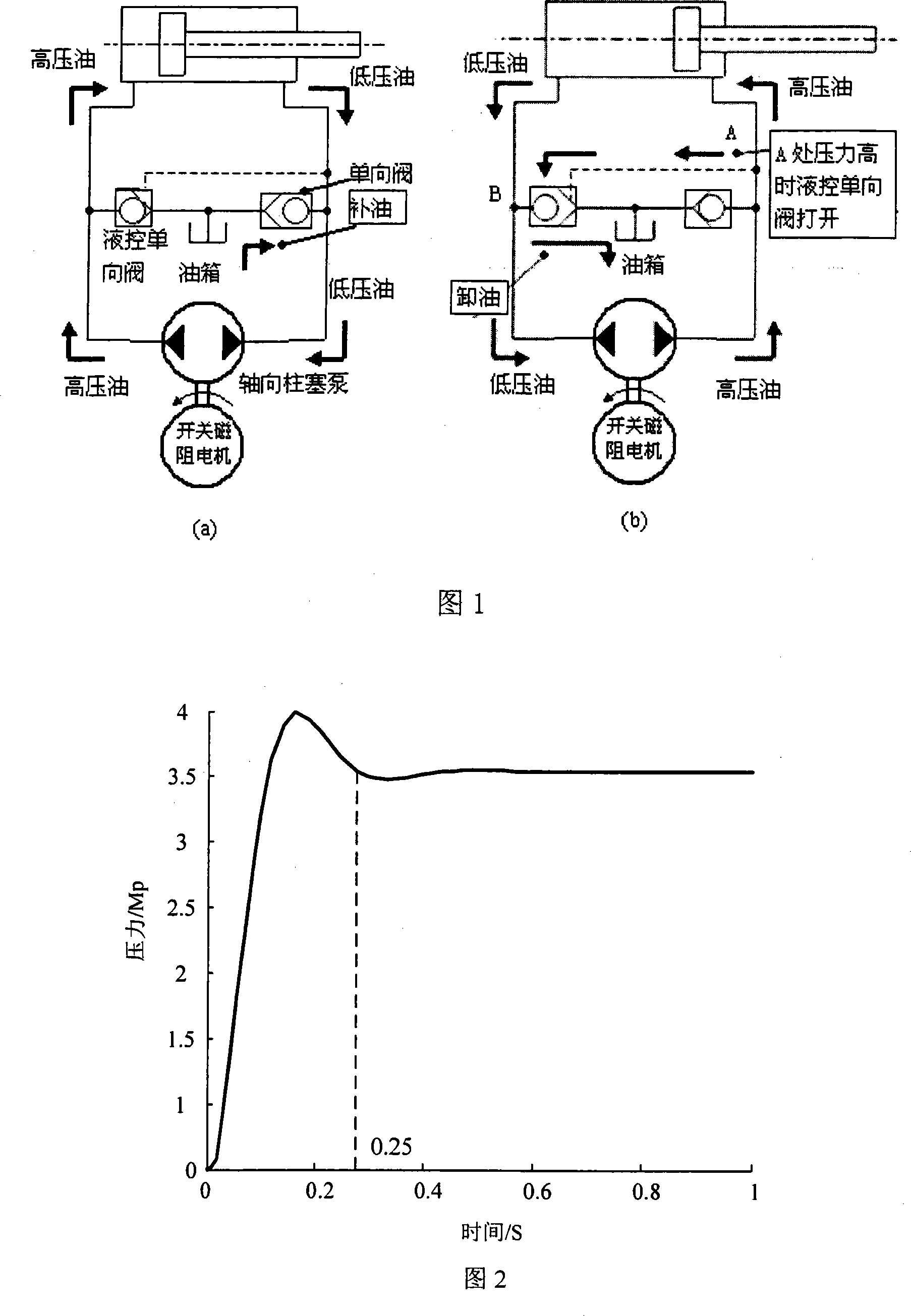

[0035] The schematic diagram of the new pump-controlled hydraulic transmission system directly servo-driven by the switched reluctance motor of the present invention is shown in Figure 2. The system includes a hydraulic cylinder with a piston in the hydraulic cylinder. It is characterized in that the two ends of the hydraulic cylinder are connected by pipelines. Axial embolism pump, the axial embolism pump is driven by a switched reluctance motor, and the switched reluctance motor realizes the reciprocating movement of the hydraulic cylinder in forward and reverse directions, and the oil tank is connected to the pipeline through a hydraulic control check valve and a check valve.

[0036] Its working principle is that the switched reluctance motor drives the axial piston pump to work and pressurizes the low-pressure oil. The low-pressure oil flows into the hydraulic cylinder after being pressurized, and pushes the piston to do work. Due to the different areas on both sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com