Light source device

A light source device and auxiliary light source technology, which is applied in the direction of light source, lighting device, point light source, etc., can solve the problems such as the increase and decrease of the ratio of the metal ring part, and the brightness of the light source device cannot be realized, so as to achieve sufficient cooling, improved cooling efficiency, The effect of high cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

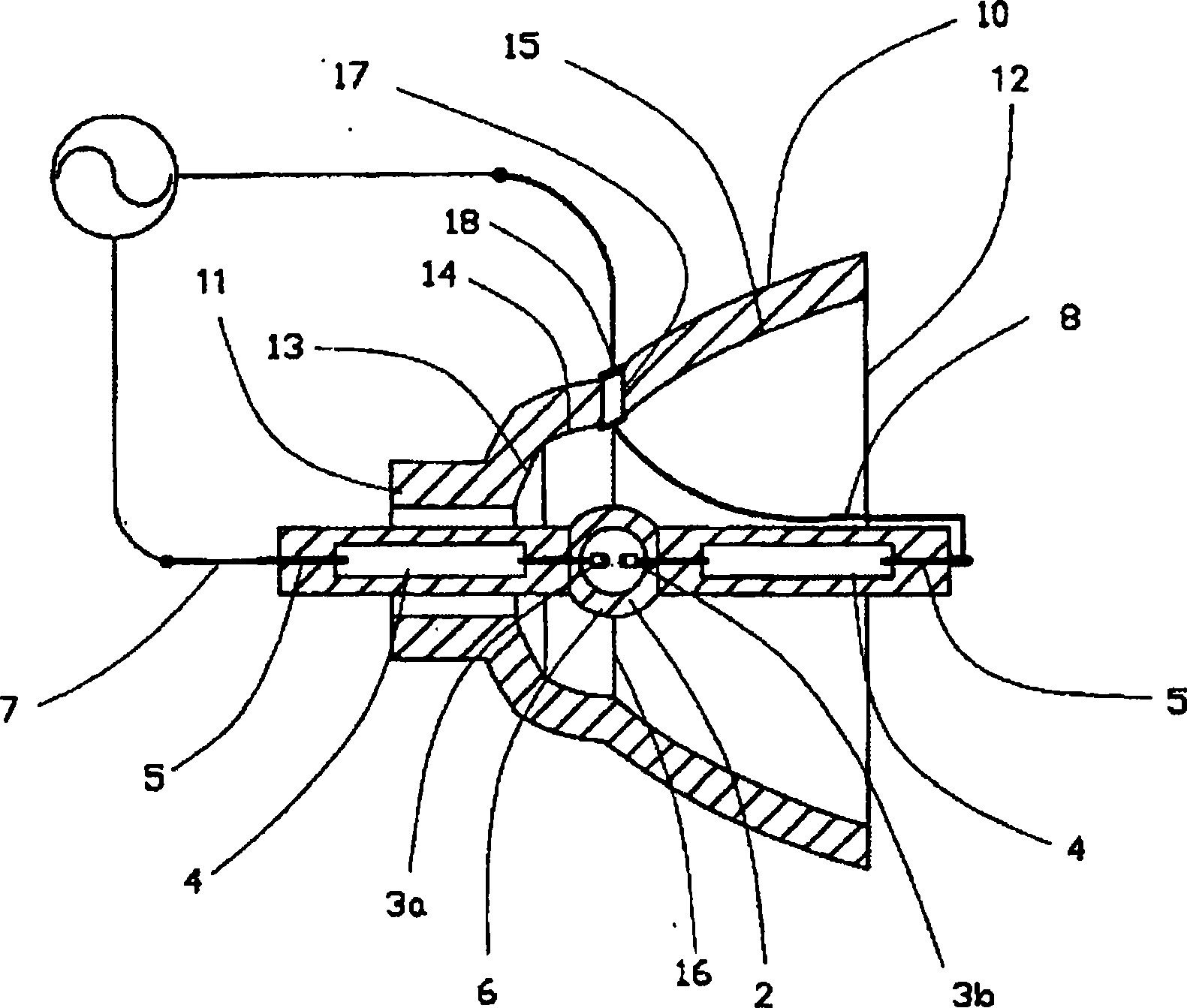

[0033] figure 1 Shows the first embodiment of the present invention. figure 1It is a light source device 1 of the present invention, and the light source device 1 is composed of a discharge lamp 2 and a reflector 10 provided to surround the discharge lamp 2 . In this discharge lamp 2, an electrode 3a and an electrode 3b are provided facing each other, and the electrodes 3a and 3b are respectively connected to a metal foil 4, and an external lead 5 is connected to the other end of the metal foil 4. As shown in FIG. The electrodes 3 a and 3 b are provided inside the bulb part 6 , and mercury, an inert gas, and a trace amount of halogen are sealed inside the bulb part 6 and sealed with the metal foil 4 . In addition, one side of the external lead 5 is connected to the power supply line 7 , and the other side is connected to the high-voltage side power supply line 8 . In addition, the reflector 10 provided around the discharge lamp 2 has a hole 11 for holding the discharge lam...

Embodiment 2

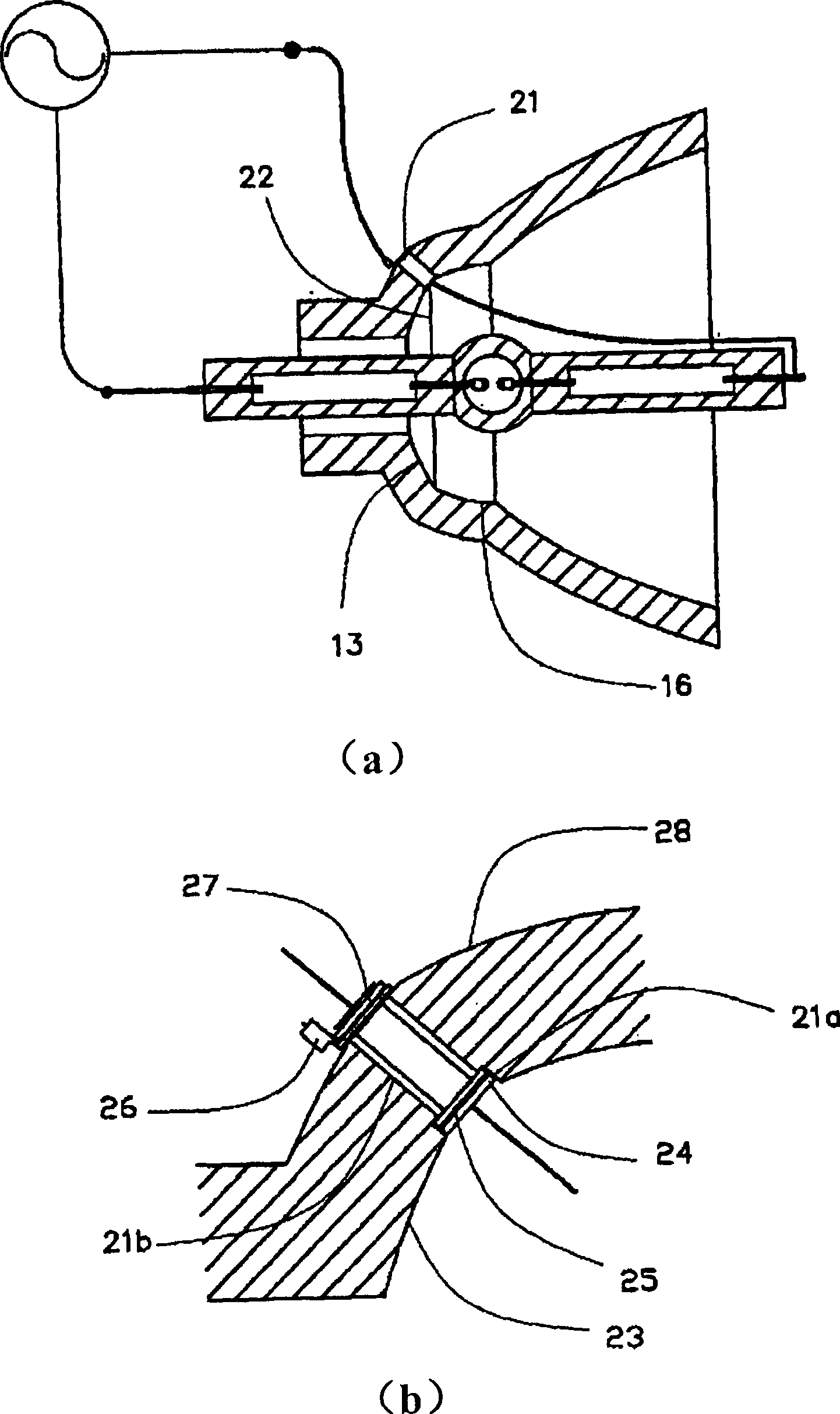

[0037] figure 2 Shows the second embodiment of the present invention. figure 2 In this case, the position where the hole is provided is different from the position where the hole 17 is provided as shown in the first embodiment. The hole portion 21 in the second embodiment is provided on the boundary portion 22 between the central reflective surface 16 and the hole-side reflective surface 13 . also, figure 2 -b) shows an enlarged view of the hole portion 21 . The hole portion 21 is composed of a counterbore 21a with a large diameter and a through hole 21b with a small diameter. As the structure of the outlet 18, for example, a flanged metal cylindrical tube 24 is passed through a hole provided in the buffer member 25 to be inserted into the hole 21, and a metal member is passed through on the back side 28 of the reflection surface 23. 26, and then pass through the hole of the gasket 27, and then use a special clamp to press the end of the metal cylindrical tube with flan...

Embodiment 3

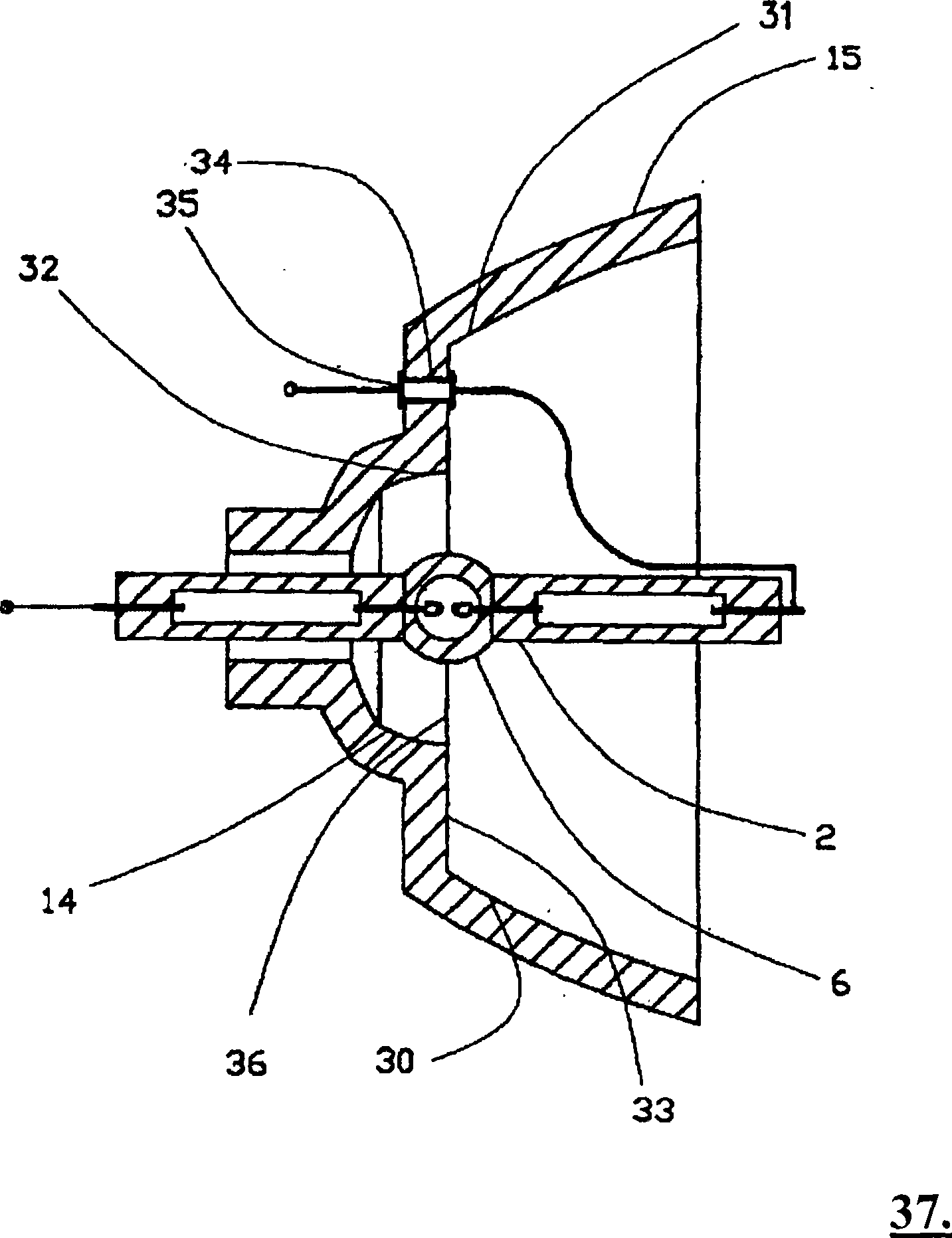

[0041] Figure 4 shows the third embodiment. The reflecting mirror 40 in this embodiment is provided with a boundary portion 43 between the central reflecting surface 14 and the opening-side reflecting surface 15 near the center of the bulb portion 6 of the discharge lamp 2 provided in the reflecting mirror 40 . Cooling air blowing holes 41 are provided on the boundary portion 43 . The cooling air blowing hole 41 is provided on the top side of the bulb with the highest temperature when the discharge lamp 2 is turned on. In addition, in this embodiment, the second cooling air blowing hole 42 is formed on the boundary portion 44 between the central reflection surface 14 and the hole-side reflection surface 13 . According to this configuration, when the discharge lamp 2 is turned on, the top of the bulb with the highest temperature can be cooled intensively, and by adjusting the temperature distribution of the entire discharge lamp 2, a long-life light source device can be prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com