Mixed vapour condensation intensify heat transmission method

A technology of steam condensation and heat transfer enhancement. It is applied in heat transfer modification, heat exchange equipment, lighting and heating equipment, etc. It can solve the problems of increasing mixed steam and power consumption, and achieve the effect of strengthening heat transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

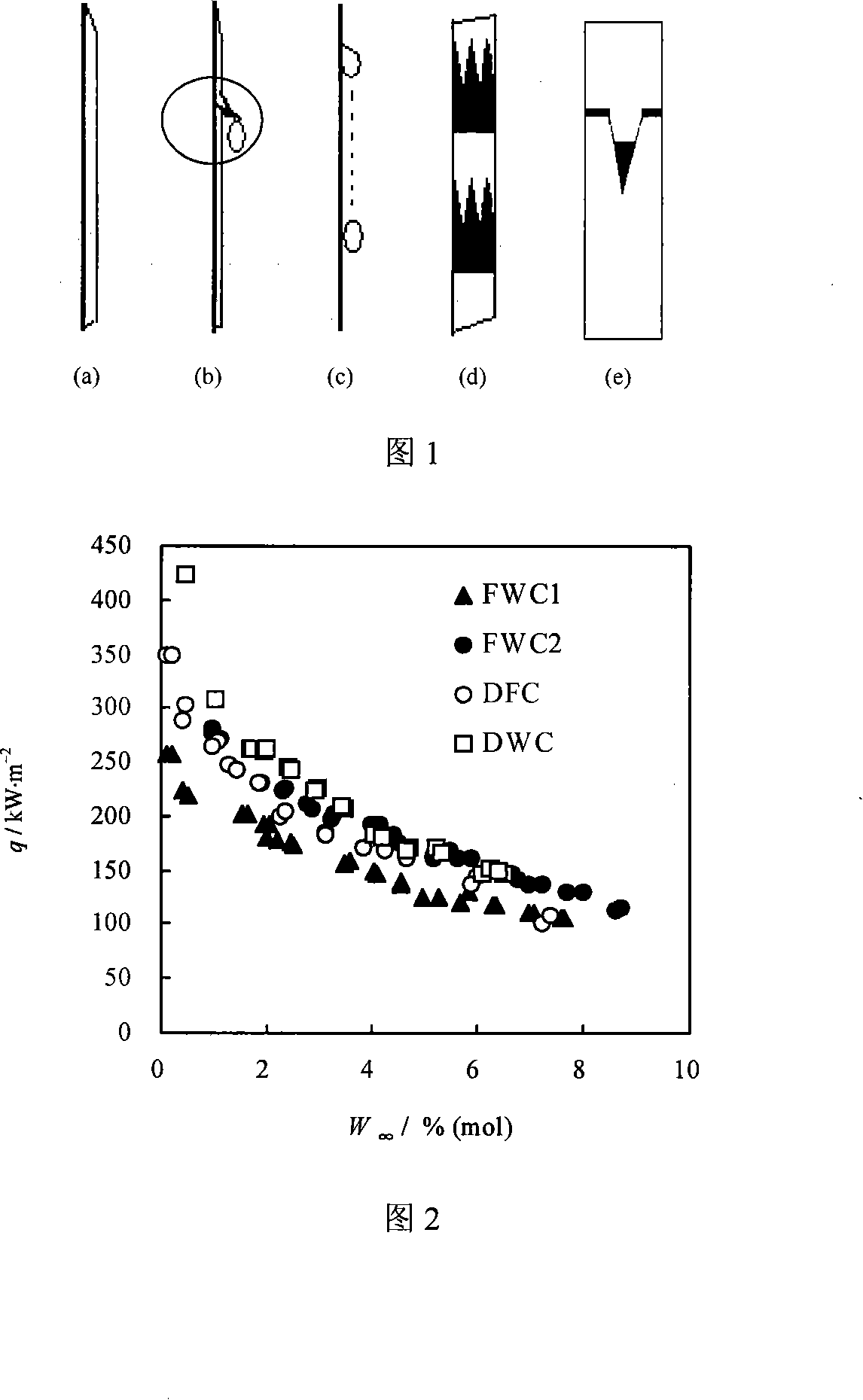

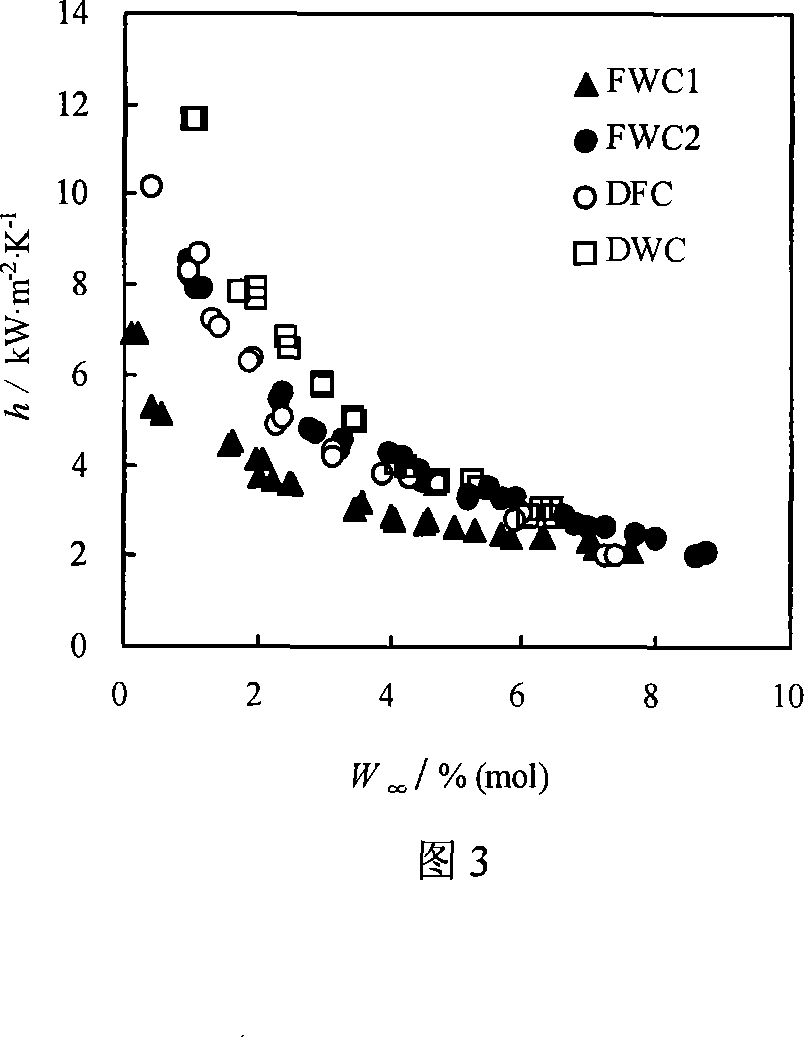

[0017]Taking a copper pipe as an example (length 400mm, Φ19mm×1mm), the effective length of the condensation section is 265mm, and its surface is modified. The design diagram of the condensation surface is shown in Figure 1, and the designed surface is condensed separately Experimental comparison of heat transfer characteristics. Figure 1(a) shows the film condensation (FWC1) commonly used in actual production. In this form, the condensate film has no obvious fluctuation phenomenon, especially when the content of non-condensable gas is large, the condensate flow rate decreases and the thickness of the liquid film Decrease, the fluctuation of the liquid film is less obvious, this is used as the control group experiment. The condensation on the surface of Figure 1(b) is also film condensation (FWC2), the difference is that a metal shut-off ring modified with Teflon surface is installed on the surface of the condensation pipe at an interval of 50mm, and two tongue-shaped Drainag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com