Resonant tuning fork structure having strong self-coupling performance

A self-coupling and tuning fork technology, which is applied in the field of core sensitive components, can solve the problems of affecting the vibration effect of the tuning fork and unfavorable signal processing of the resonant tuning fork, and achieve the effects of strengthening vibration coupling, increasing equivalent stiffness, and good differential effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

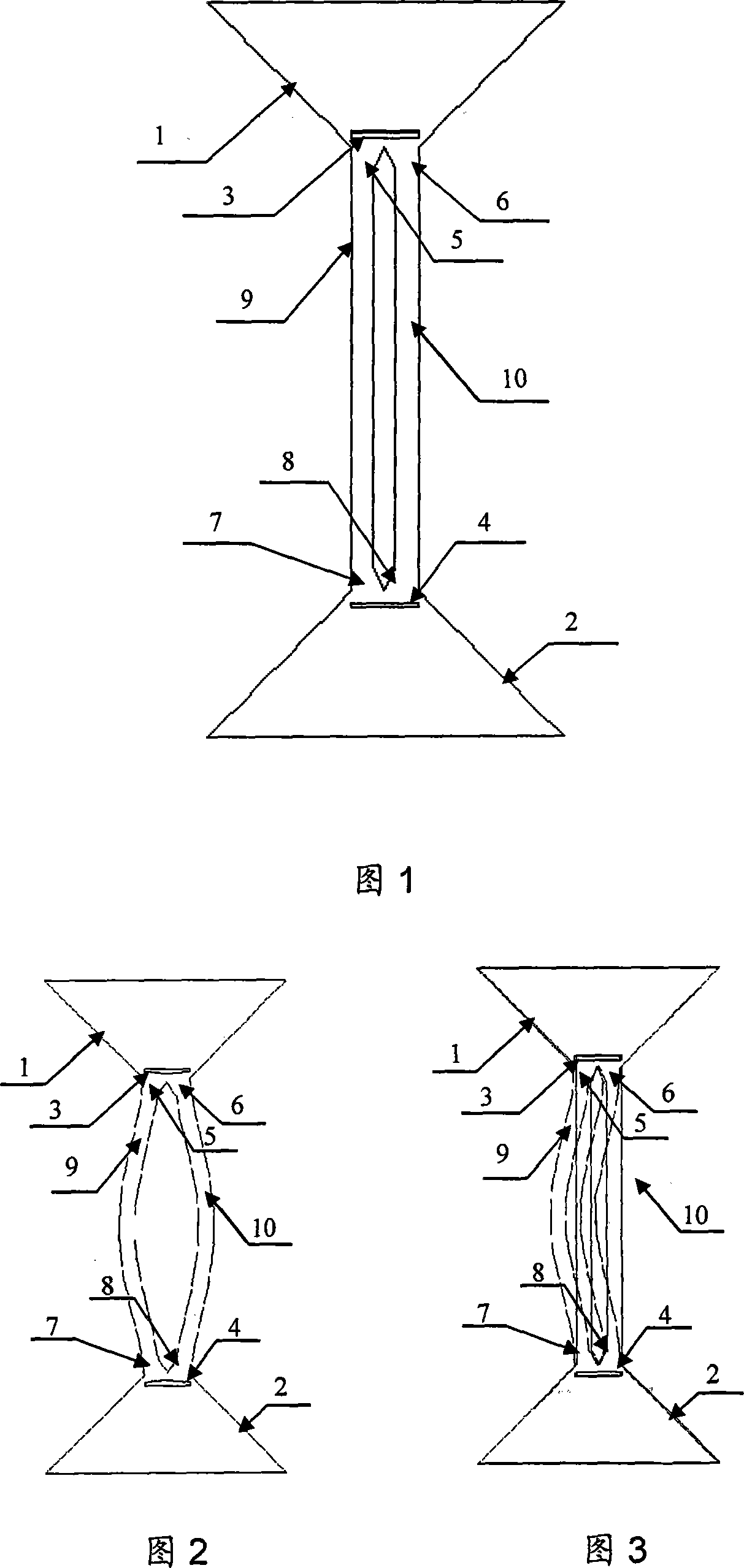

[0011] As shown in Figure 1, the present invention includes a symmetrical upper triangular base 1 and a lower triangular base 2 that are used for tuning forks to be fixedly connected to the surrounding two triangles, and an upper vibration isolation hole 3 in the upper triangular base 1. It is symmetrical with the lower vibration isolation hole 4 located in the lower triangular base 2, the upper vibration isolation hole 3 and the lower vibration isolation hole 4; The left and right two symmetrical resonant beam support bases 7 and 8 are located at the upper end of the lower vibration isolation hole 4, and the left and right symmetrical resonant beams 9 and 10 are located in the middle of the entire tuning fork structure, forming a resonant tuning fork, and through the left and right upper resonant The beam support bases 5, 6 and the left and right lower resonant beam support bases 7, 8 are supported between the upper triangular base 1 and the lower triangular base 2, and are ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com