Method for welding FPC plate with PCB plate and its dedicated clamp

A technology of PCB board and welding method, which is applied in the field of welding of FPC board and PCB board and its special fixture, can solve the problems of affecting product quality, high welding cost, poor product reliability, etc., and achieve good consistency of welding temperature curve, welding High reliability and small product temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

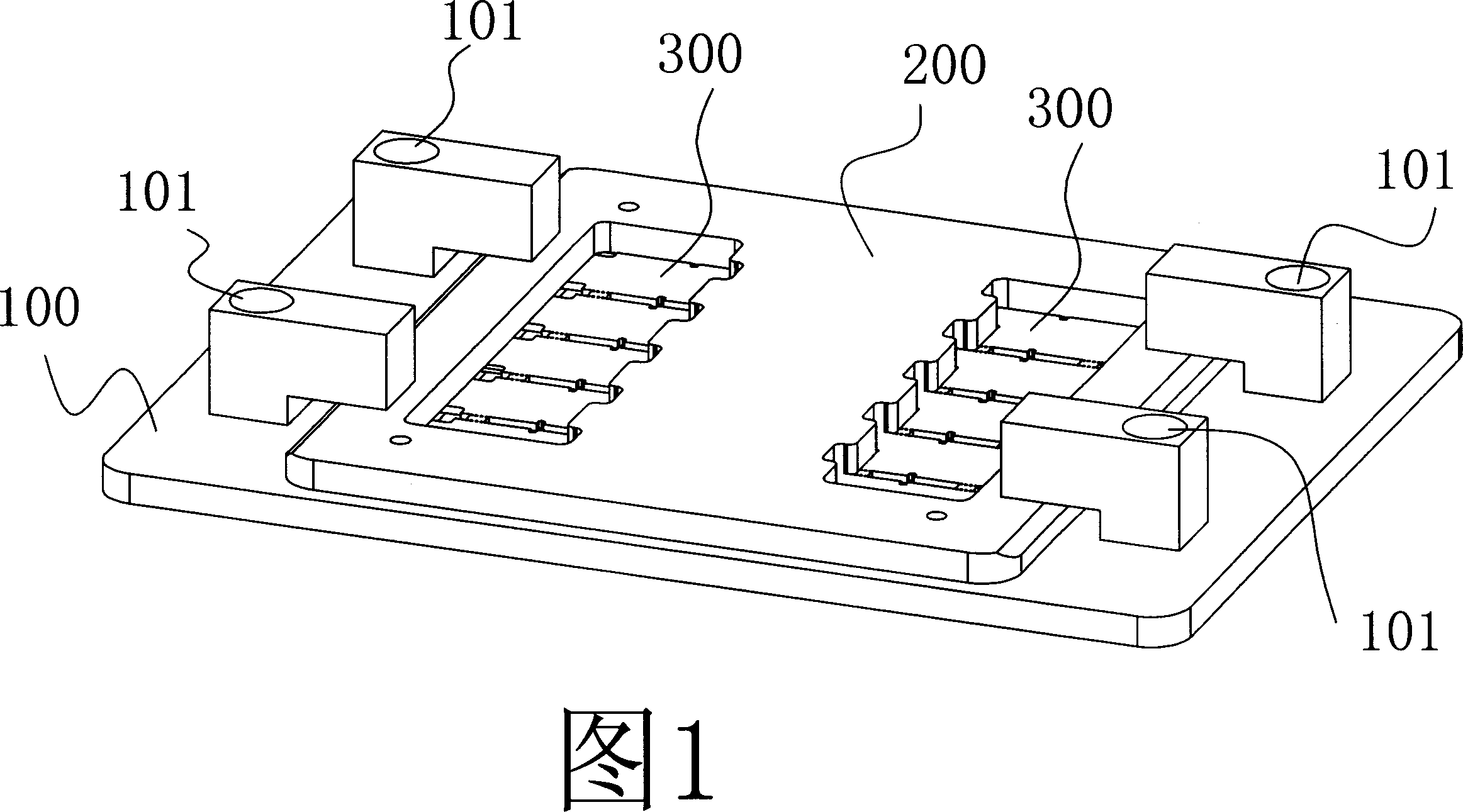

[0032] As shown in FIG. 1 , the special fixture includes: a lower template 100 and an upper template 200 , and a PCB board 300 is sandwiched between the two templates.

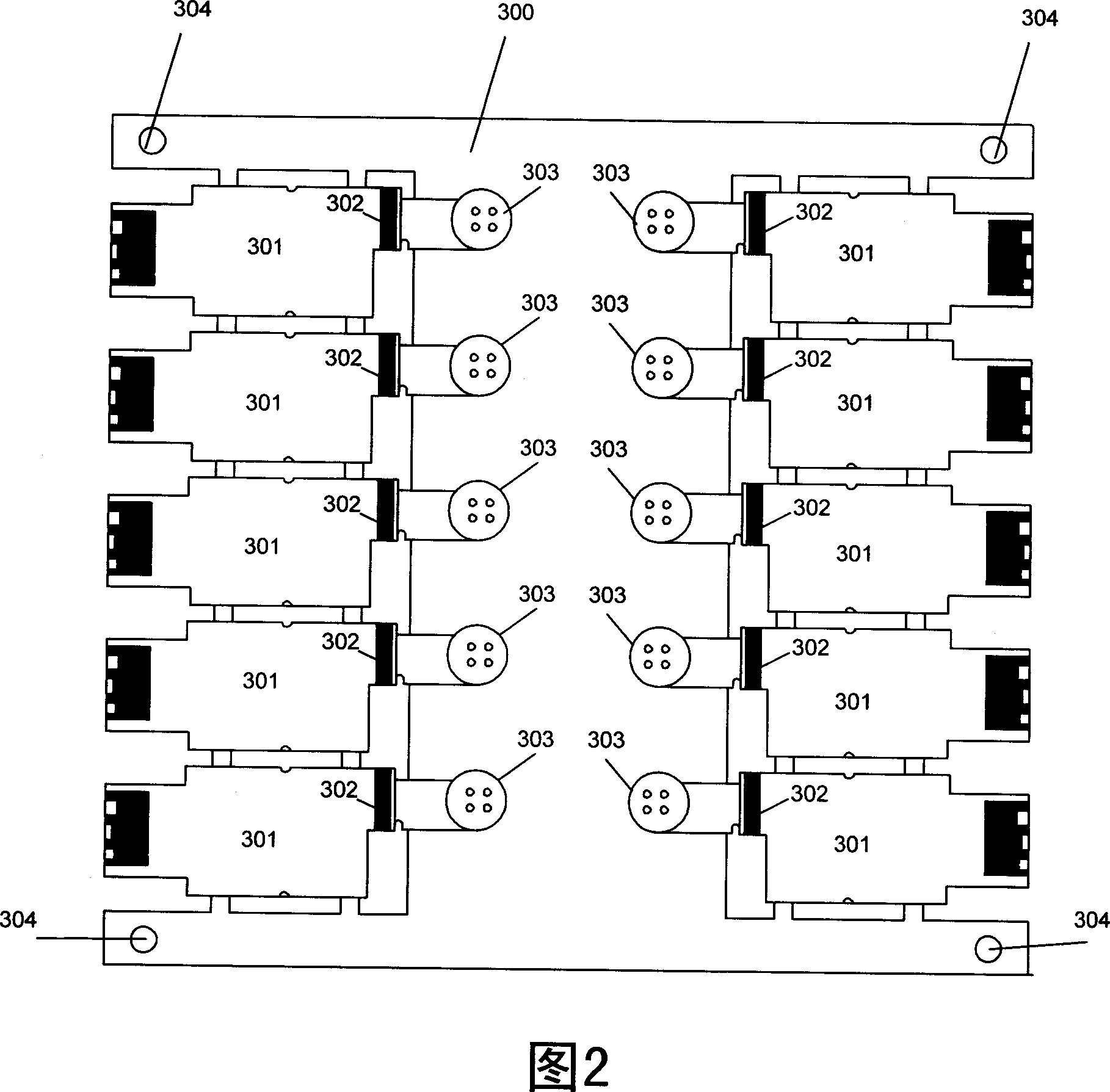

[0033] As shown in Figure 2, the PCB board 300 is a large piece formed by more than one small PCB board 301. There must be enough space for mounting the FPC board 303 on the PCB board 300, and each PCB board 301 can be welded at least A piece of FPC board 303 and four corners of PCB board 300 are symmetrically provided with positioning holes 304 . In this embodiment, 10 small PCB boards 301 are joined together to form a large PCB board 300, and the edge of each small PCB board 301 has a pad position 302 connected with the FPC board 303, and the pad position 302 can be located on the PCB the middle of the small board 301 .

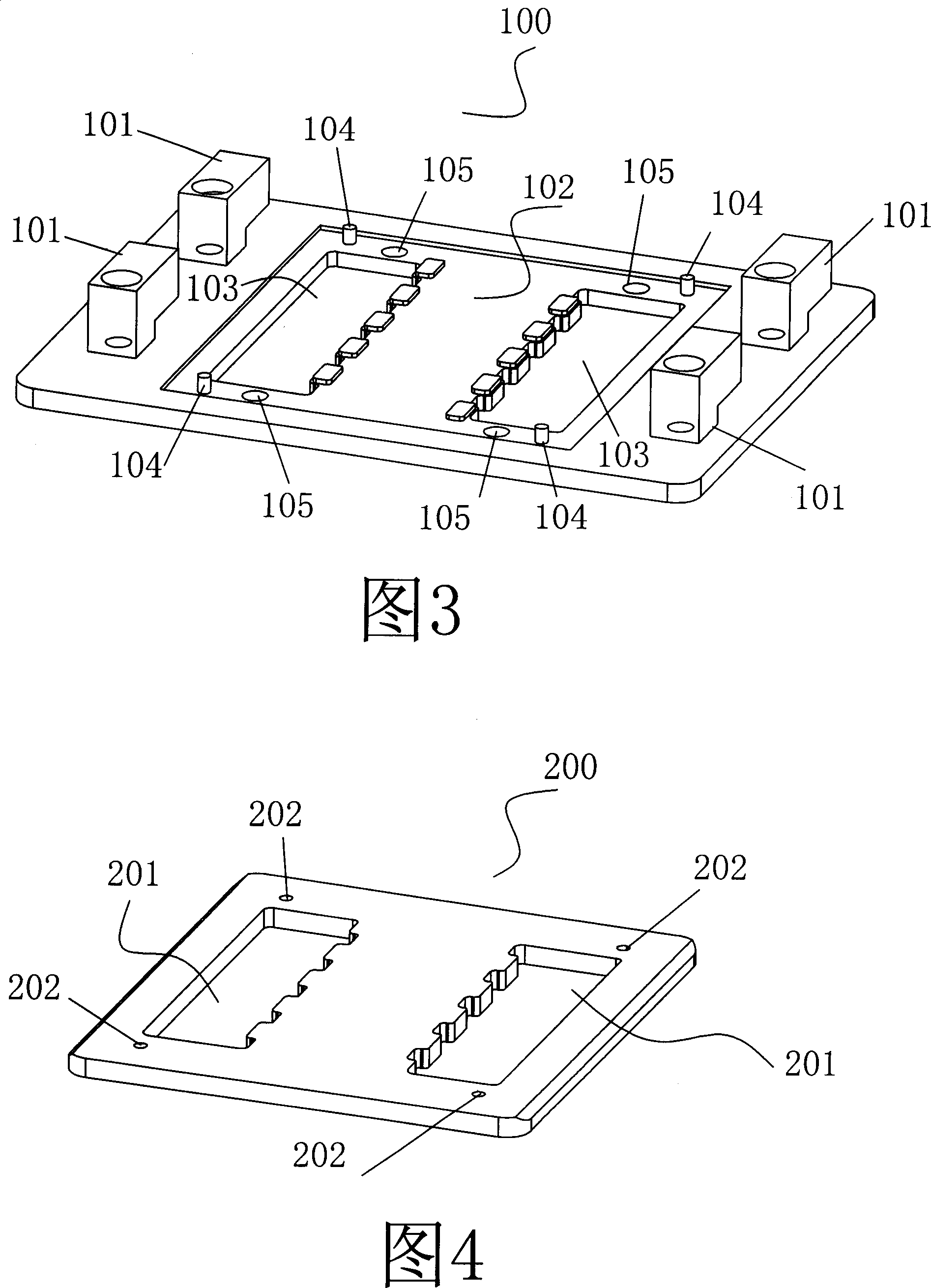

[0034] As shown in Figure 3, the lower formwork...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com