Double-screen filter-pressing wash hollander

A technology of filter washing and pulp machine, which is applied in the direction of pulp bleaching, etc. It can solve the problems of affecting production capacity, increasing power consumption, and large wear of contact parts, and achieves the effects of easy maintenance and use, reducing power consumption and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

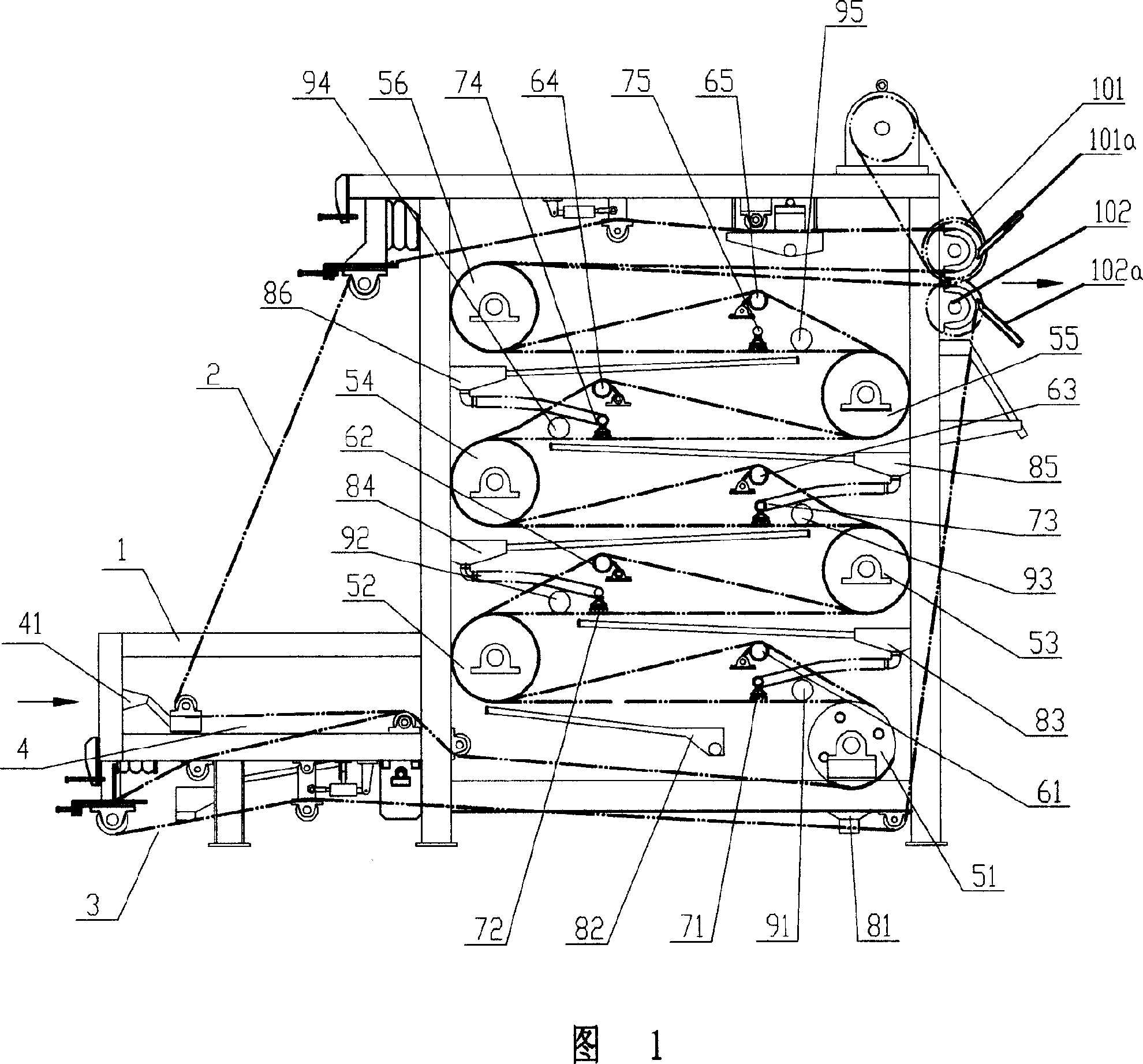

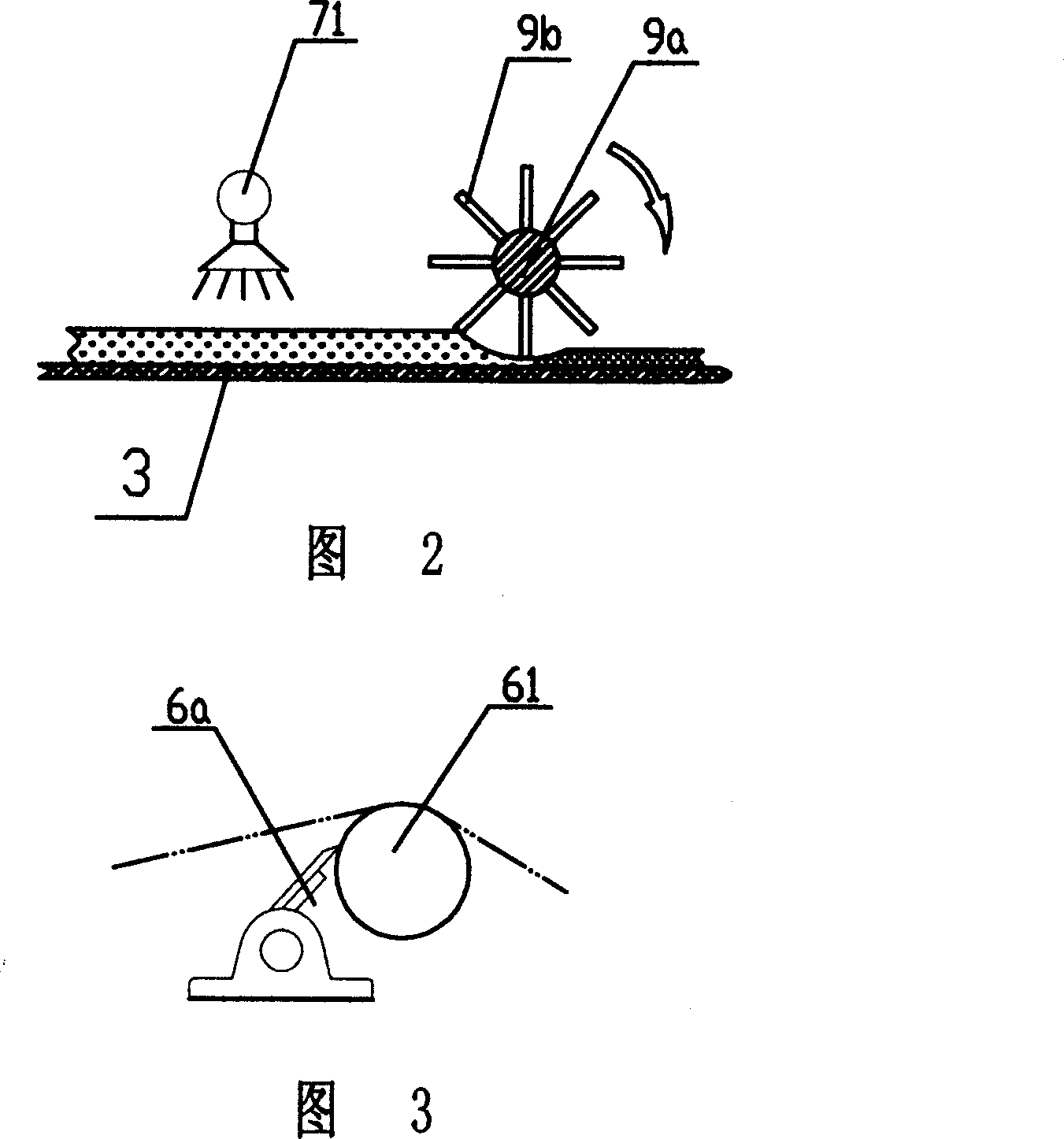

[0020] As shown in Figure 1, Figure 2, and Figure 3, the double-screen filter press pulp washer includes a frame 1, a number of screen rolls installed on the frame 1, and a screen 2 installed on a number of screen rolls and closed-cycle movement, The lower wire 3 which is installed on several screen rollers and moves in a closed cycle, the feeding port 41 of the upper wire 2 and the lower wire 3 has a pulp distribution area 4, and the upper wire 2 and the lower wire 3 are located behind the pulp distribution area 4 There are several dewatering rolls 51, 52, 53, 54, 55, 56 as public net rolls, and the several dewatering rolls 51, 52, 53, 54, 55, 56 form several overlapping presses of the upper net 2 and the lower net 3. In the filter area, the plurality of dewatering rollers (51, 52, 53, 54, 55, 56) are vertically arranged in two rows, and the adjacent two dewatering rollers 51, 52, 53, 54, 55, 56 Pulp washing water spraying devices 71, 72, 73, 74, 75 positioned between the twi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com