Highly effective quick-speed anti-seep plugging technology for cofferdam

A technology of cofferdam and technology, which is applied in the direction of construction and infrastructure engineering, etc., can solve problems such as insufficient slurry diffusion radius, leakage irrigation, failure of cofferdam anti-seepage, etc., and achieve obvious anti-seepage effect, significant economic and social benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

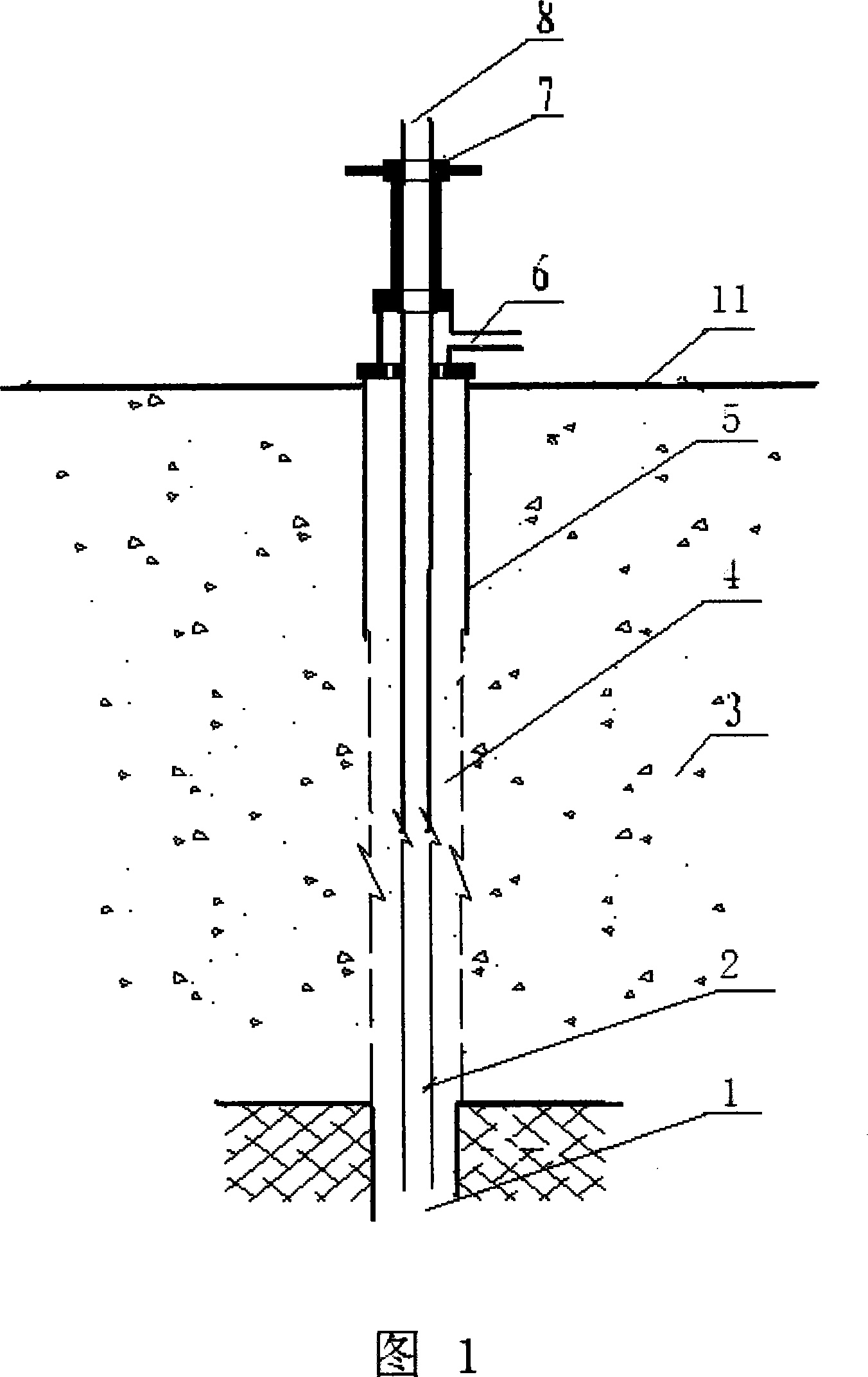

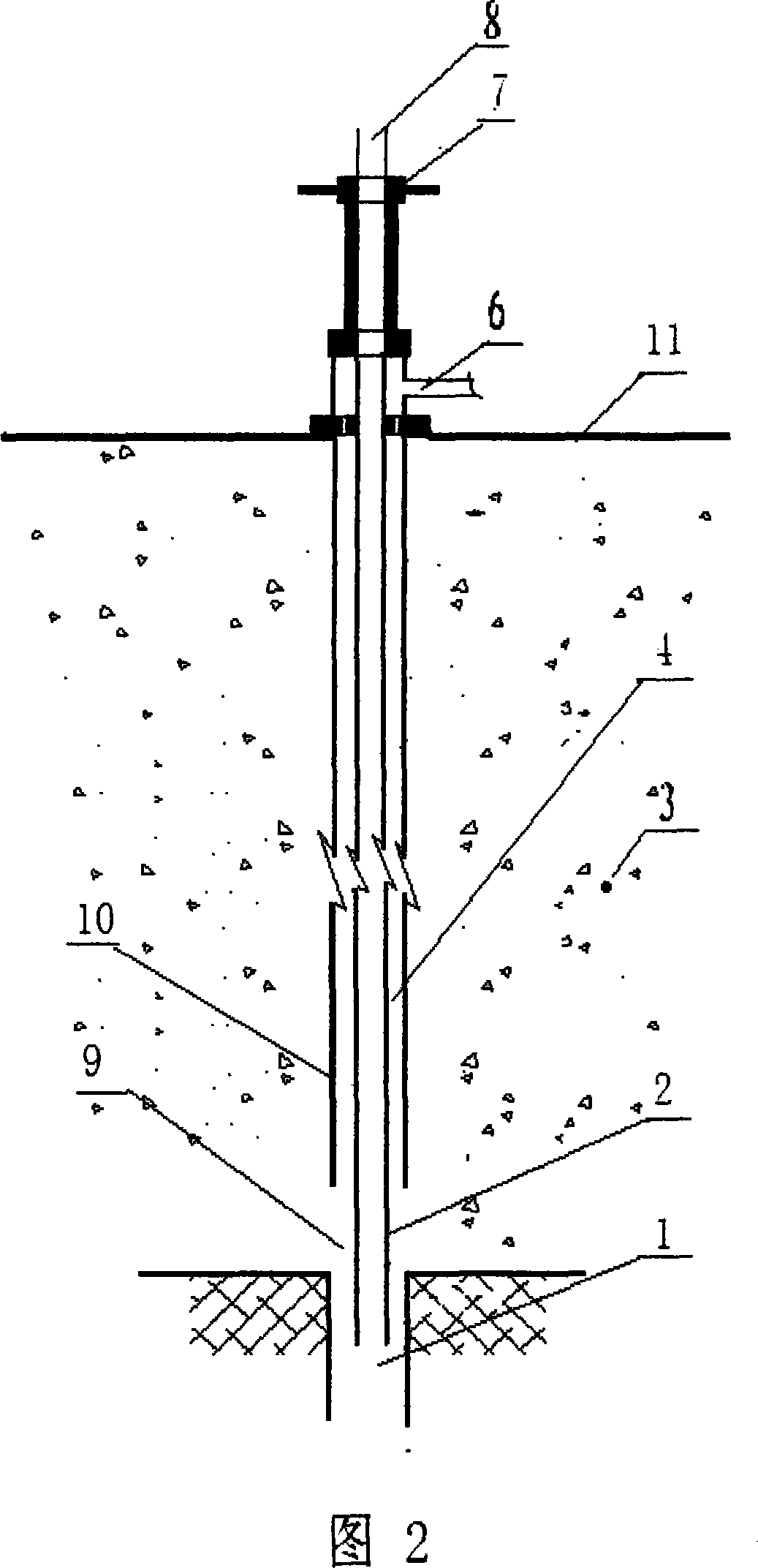

[0029] Embodiment: Describe the specific implementation process through construction practice

[0030] 1 drilling

[0031] The whole hole is drilled with a pneumatic down-the-hole drill eccentrically with the pipe, and the drilling diameter is generally φ130mm~φ160mm. The drilling rig uses the SM3000A down-the-hole drilling rig. For the cofferdam whose hole depth is not greater than 25m, the MG-80 bolter drilling rig can also be used for drilling, but the drilling speed is not as fast as the down-the-hole drilling machine. Each drilling rig needs to be equipped with 20m 3 / min air compressor for air supply, equipped with necessary drill pipe and steel casing. After the drilling is completed, after the grouting and injection pipeline is installed, use the tube pulling machine to pull out the casing in the hole.

[0032] 2 grout

[0033] After grouting with this technology, firstly do not accelerate the coagulation material in the grout, but when the grout consumption reache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com