High vacuum well -points dewatering ground treatment method

A well point precipitation and foundation treatment technology, applied in infrastructure engineering, soil protection, construction, etc., can solve the problems of excessive static pore water pressure not easily dissipated, unable to function on soft soil foundation, unable to be promoted on a large scale, etc. The effect of good foundation reinforcement, high construction efficiency and short period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

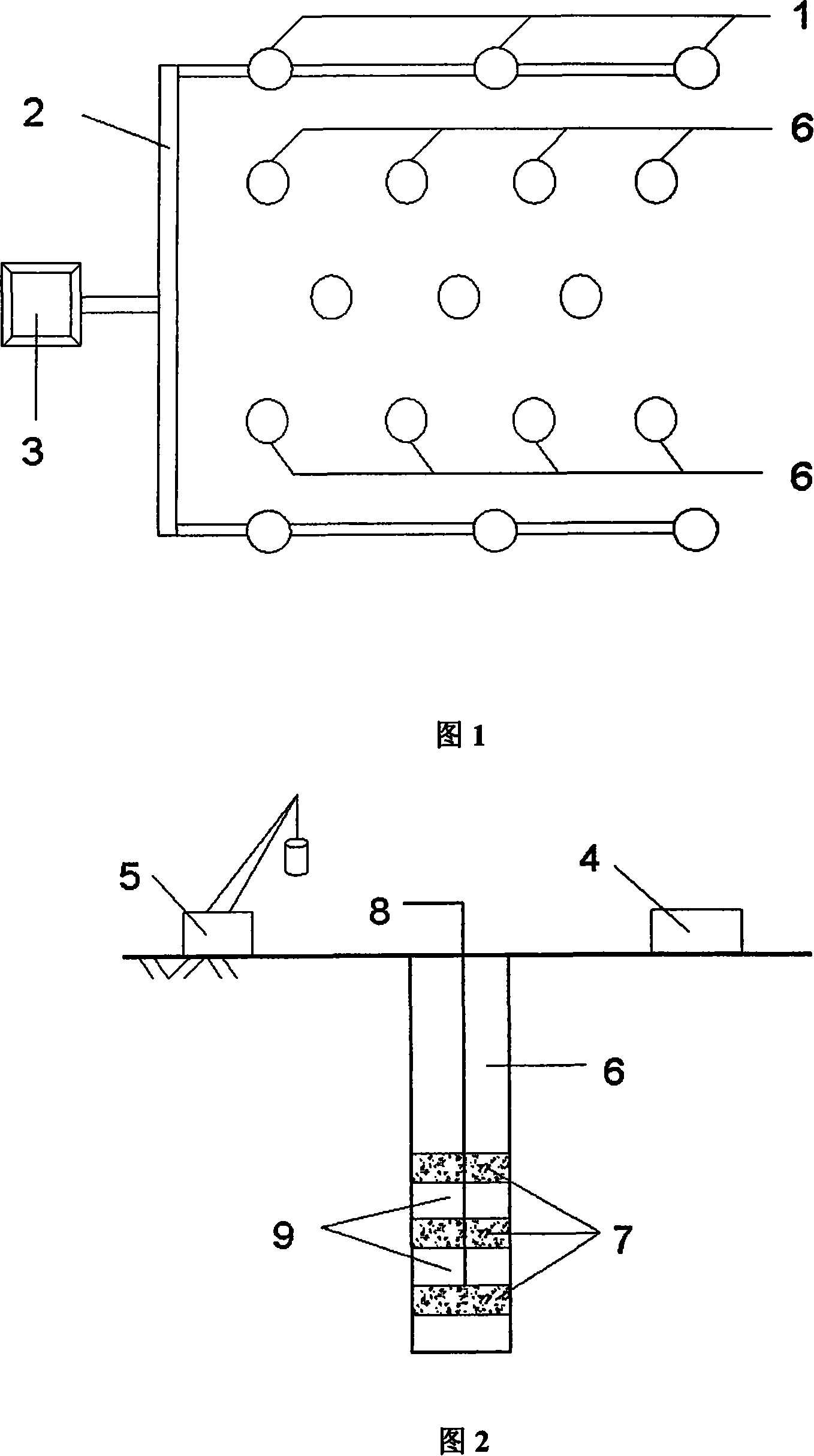

[0027] As shown in Figures 1 and 2, the well point pipe 1 is vertically inserted in a large area in the reinforced area, the well point pipe is inserted to a depth of 8-18m, the well point pipe 1 is connected to the main water collection pipe 2, and the main water collection pipe 2 is connected to the vacuum pump 3 , Start the vacuum pump 3 to drain water and lower the groundwater level, and the shallow foundation soil is consolidated. Pull out the well point pipe, arrange vibratory rolling machine 4 or dynamic ramming equipment 5 on the ground of the reinforced area, start the vibratory rolling machine 4 or dynamic ramming equipment 5 to make the shallow foundation soil in the reinforced area compact, and make the shallow layer The pore water in the soil skeleton is precipitated. Withdraw the vibratory rolling machine or dynamic compaction equipment, and drill a number of explosion holes 6 to 8 to 18m with a drilling rig. The explosion holes 6 are arranged in a triangle or qu...

Embodiment 2

[0029] As shown in Figures 1 and 2, insert the well point pipe 1 vertically in the reinforced area. The depth of the well point pipe is 8-18m. 3 Drain down the groundwater level and consolidate the shallow foundation soil; pull out the well point pipe, and use a drilling rig to drill out the well point explosion holes 6 to 8 to 18m. 12m, place one or several vertical tubular explosives 7 and lead out fuses 8 along the depth in the blast hole 6, the explosives 7 are blocked and separated by sand and gravel 9, and the explosives in the explosives are water-resistant plastic explosives. Ignite the fuse 8 to detonate the explosive package 7 in the deep foundation explosion hole, so that the deep foundation soil is compacted, and the pore water in the deep soil skeleton is separated out; the vibration rolling machine 4 or the dynamic compaction equipment 5 are arranged on the ground to start the vibration The rolling machine 4 or the dynamic tamping device 5 compacts the shallow fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com