Protection circuit and battery pack

A technology for protecting circuits and circuit boards, applied to emergency protection circuit devices, circuits, secondary batteries, etc., can solve the problems of excessive circuit scale, battery expansion, low precision, etc., and achieve the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

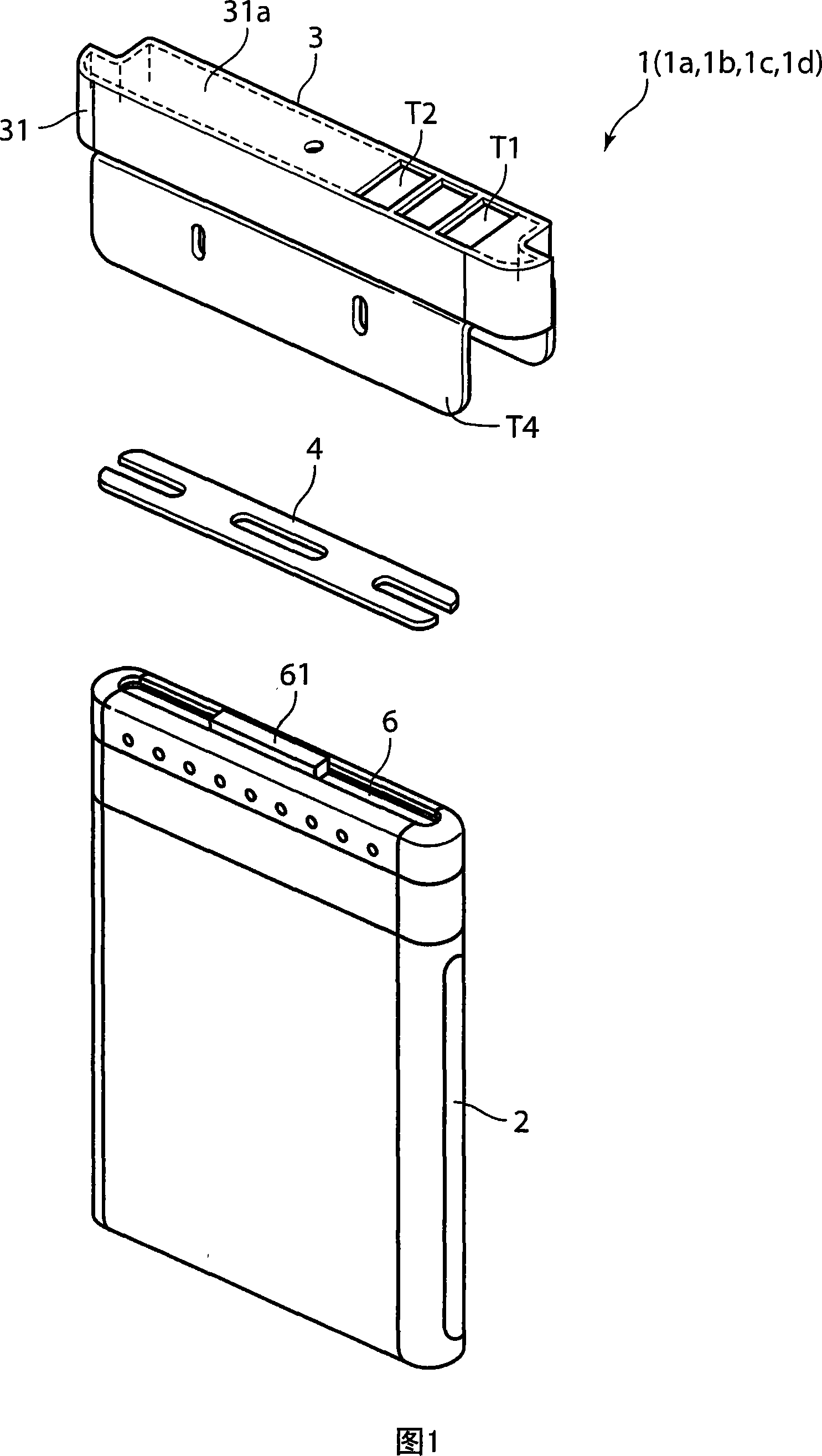

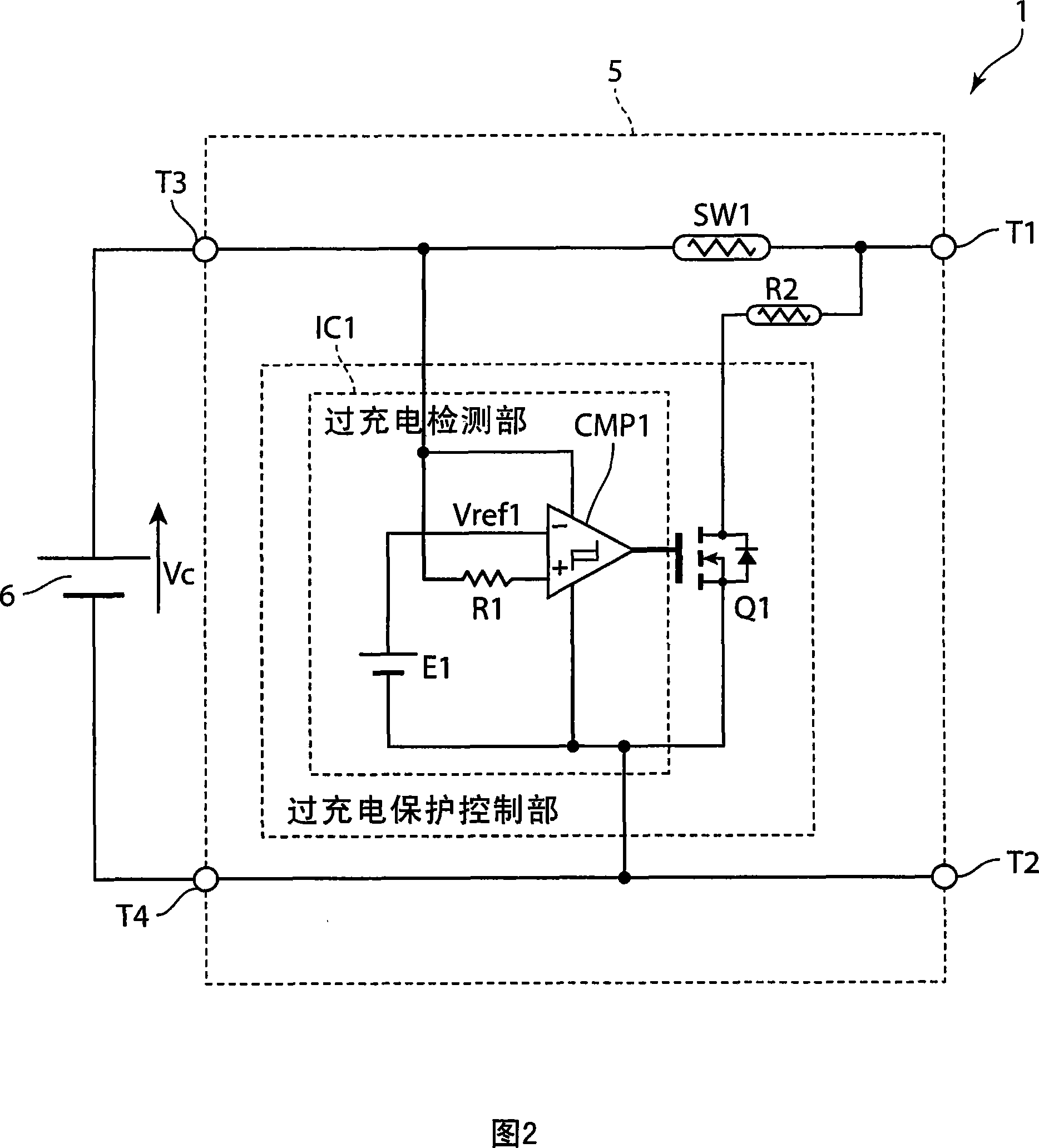

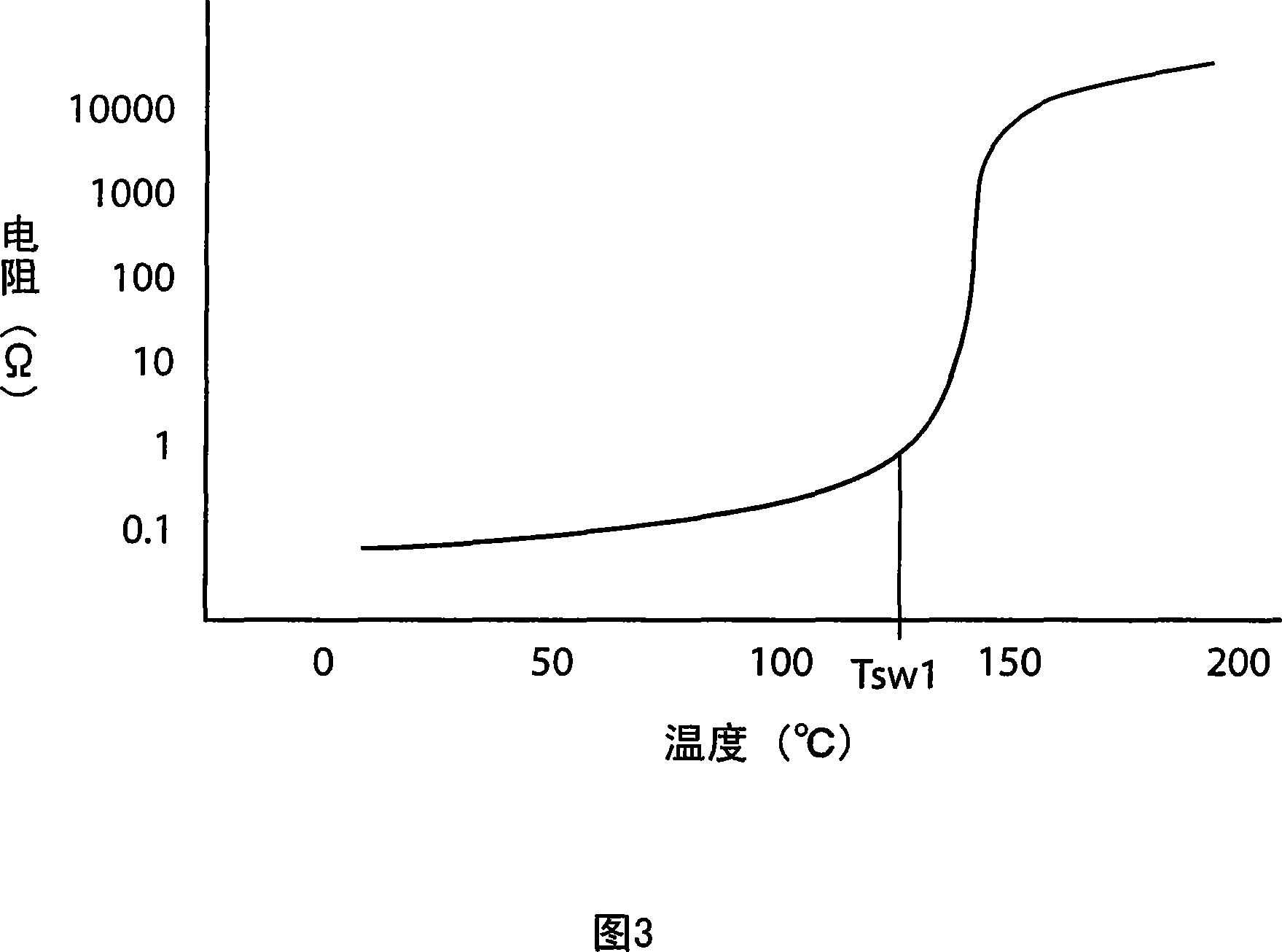

[0041] FIG. 1 is an exploded perspective view showing an example of a battery pack according to a first embodiment of the present invention. A battery pack 1 shown in FIG. 1 has a bottomed container 2 , an external connection terminal unit (Unit) 3 , and a plate-shaped spacer (Spacer) 4 inserted between the container 2 and the external connection terminal unit 3 . A secondary battery 6 is housed in the container 2 and sealed by crimping. A positive terminal 61 protruding from the secondary battery 6 protrudes from the open end of the container 2 . Furthermore, the container 2 is made of a nickel-plated steel plate, and the negative electrode of the secondary battery 6 is connected to the container 2 inside the container 2 .

[0042] The external connection terminal unit 3 has a case 31 formed of, for example, resin, and connection terminals T1 and T2 for connecting a charging device or a load device are provided so as to be exposed on the top of the case 31 . Furthermore, a c...

no. 2 example

[0066] Next, a battery pack according to a second embodiment of the present invention will be described. The appearance of the battery pack 1a of the second embodiment of the present invention is the same as that of the battery pack 1 shown in FIG. 1 . FIG. 4 is a circuit diagram showing an example of an electrical configuration of a battery pack 1a according to a second embodiment of the present invention. The battery pack 1a shown in FIG. 4 differs from the battery pack 1 shown in FIG. 2 in the configuration of the protection circuit 5 . That is, in the protection circuit 5 of the first embodiment, the heater R2 is connected to the terminal on the side of the connection terminal T1 of the PTC element SW1, while in the protection circuit 5a of the second embodiment, the heater R2 is connected to the PTC element SW1. The characteristic of this embodiment is that the terminals on the side of the secondary battery 6 of the element SW1 are connected.

[0067] Next, the operatio...

no. 3 example

[0075] Next, a battery pack according to a third embodiment of the present invention will be described. The battery pack 1b of the third embodiment of the present invention has the same appearance as the battery pack 1 shown in FIG. 1 . FIG. 5 is a circuit diagram showing an example of an electrical configuration of a battery pack 1b according to a third embodiment of the present invention. The battery pack 1b shown in FIG. 5 is different from the battery pack 1 shown in FIG. 2 in the structure of the protection circuit 5b. That is, in the protection circuit 5b shown in FIG. 5, compared with the protection circuit 5, the heater R2 is removed, and the overcharge prevention transistor FET1 is connected to the PTC element SW1. The transistor (switching transistor) Q1 included in the integrated circuit IC1 is The characteristic of this embodiment is.

[0076] The overcharge prevention transistor FET1 is a p-channel field effect transistor, its gate is connected to the drain of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com