Boning out method for ham

A technology for ham and carcass, which is applied to the processing field of finished ham, can solve the problems of small ham meat and air, loss of ham flavor and high peroxide value, and achieve the effect of long-term preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Fresh legs are received from raw materials → trimmed leg embryos → pickled → soaked legs → washed legs → dried legs → singeed → shaped → fermented → dried knives → fermented storage → shelf grading → turned over and rubbed oil, and finally The finished ham is made.

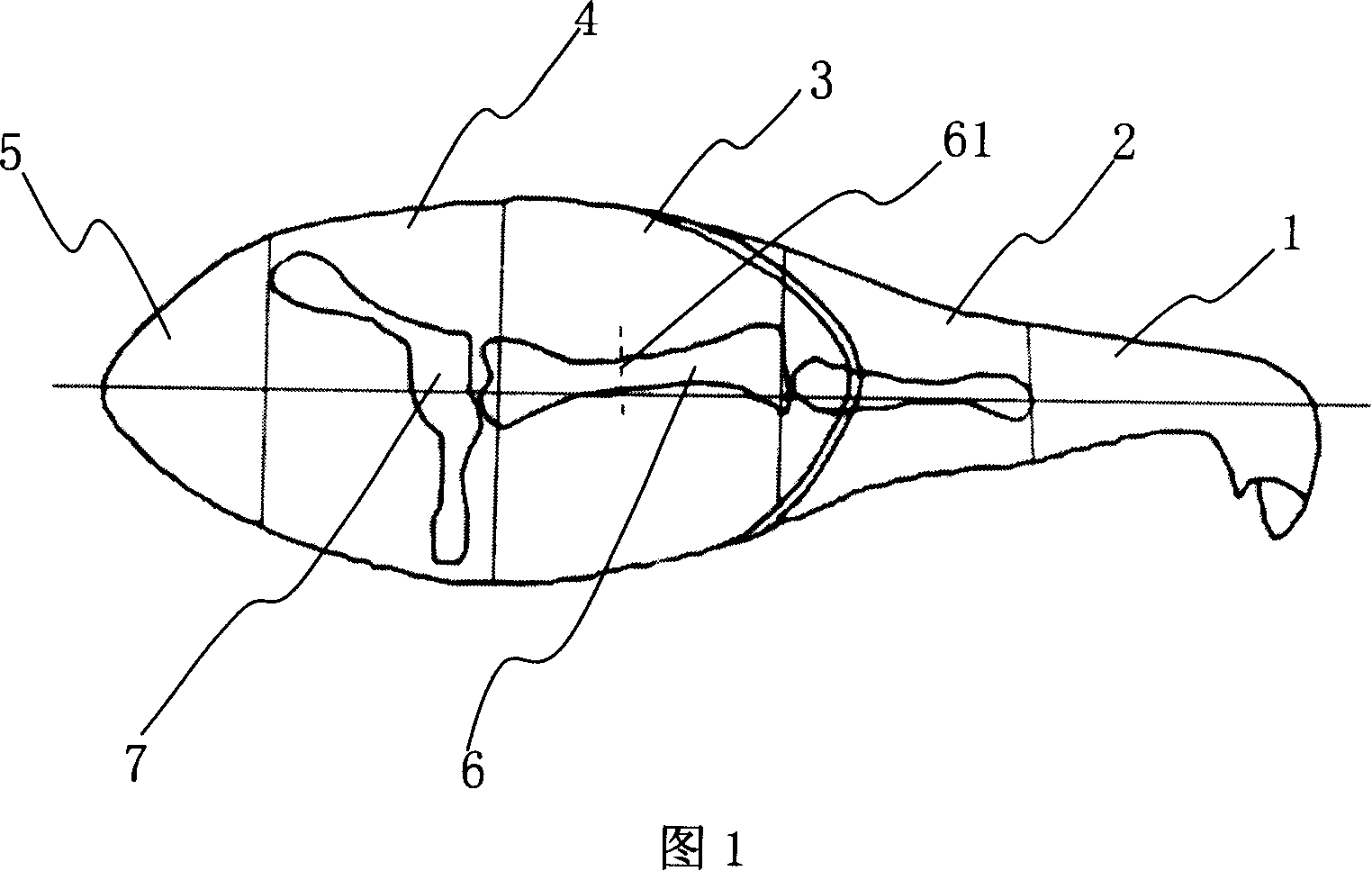

[0019] As shown in Figure 1, the finished ham is mainly composed of five parts: the fire claw 1, the fire heel 2, the middle part 3, the upper part 4 and the drip 5. For the convenience of consumers, before leaving the factory, the finished ham should be sawn off the fire claw part 1 and the fire heel part 2 of the ham, which are mainly bones; determine the position of the carcass 6 at the middle 3 part of the ham, and use a diameter of 0.2 A mm copper wire saw cuts the carcass 6 laterally from the middle position 61 of the carcass 6; cut the meat along the eyebrow bones with a knife, and remove the eyebrow bones 7 of the ham with a deboning knife; fix the ham and saw off from the fire heel Use a kni...

Embodiment 2

[0021] Example 2: First, determine the position of the carcass in the middle of the ham. A copper wire saw with a diameter of 0.3mm is used to cut the carcass transversely from the middle of the carcass; the fire claws and fires on the ham are mainly the bones. Heel part; use a knife to cut the meat along the eyebrow bone, and remove the eyebrow bone of the ham with a deboning knife; fix the ham and lengthen the cut from the fire heel with a knife blade, and the deboning knives on both sides of the knife tip penetrate into the ham , Separate the bones from the meat and take out half of the carcass; insert the ham from the cut eyebrow bones, separate the bones from the meat, and take out the other half of the carcass.

Embodiment 3

[0022] Example 3: First determine the position of the carcass located in the middle of the ham, and cut the carcass transversely from the middle of the carcass with a copper wire saw with a diameter of 0.25mm; then use a knife to cut the meat along the brow bone and deboning The eyebrow bones of the ham are removed with a knife; then the fire claws and fire heel parts of the ham, which are mainly bones, are sawn off; the ham is fixed, and the cutting edge is extended with a blade from the fire heel saw, and the deboning knives open on both sides of the knife tip to extend Insert the ham, separate the bones from the meat, and take out half of the carcass; extend the ham from the cut eyebrow bones, separate the bones from the meat, and take out the other half of the carcass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com