Mixer for asphalt and rubber powder in equipment for producing rubber asphalt

A technology for production equipment and rubber asphalt, applied in the direction of fluid mixers, mixers, chemical instruments and methods, etc., can solve the problems of inconvenient use and maintenance, high price, complex structure, etc., and achieve convenient use and maintenance, production The effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

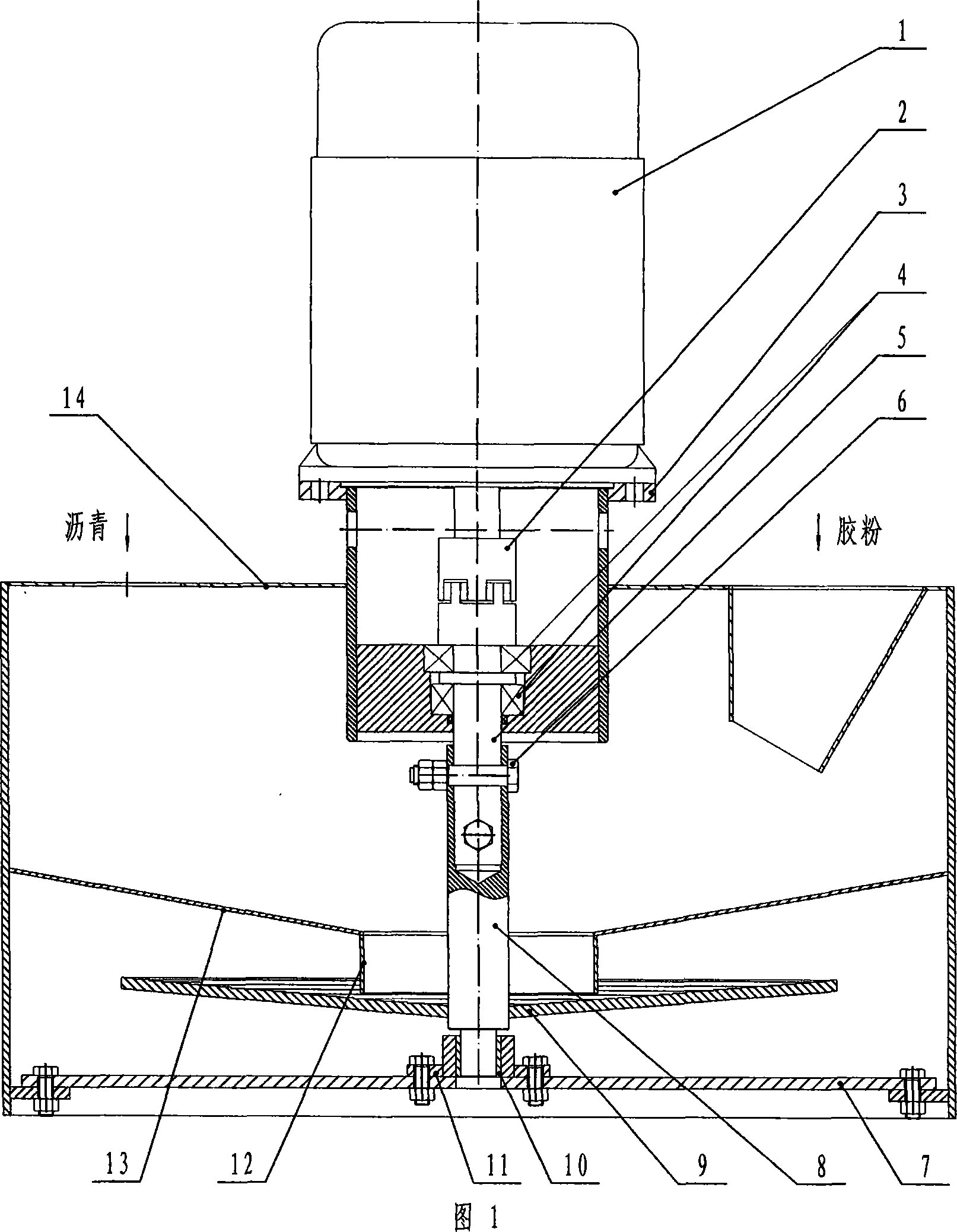

[0023] In Fig. 1, the asphalt and rubber powder mixer of the rubber asphalt production equipment of the present embodiment is composed of a motor 1, a shaft coupling 2, a support seat 3, an upper bearing 4, a transmission shaft 5, a hinged bolt 6, a bracket 7, and a sprinkler. The material tray shaft 8, the material spreading plate 9, the lower bearing 10, the bearing seat 11, the retaining ring 12, the mixing hopper 13, and the tank body 14 are connected to form.

[0024] A support seat 3 is welded and connected to the center of the upper end of the tank body 14. Two feed ports are processed on both sides of the upper end of the tank body 14, one feed port for liquid asphalt, and the other feed port for rubber powder, liquid asphalt and The rubber powder is mixed in the tank body 14. The lower side wall in the tank body 14 is welded and connected with a mixing hopper 13, and the lower end of the mixing hopper 13 is welded and connected with a retaining ring 12. The shape of t...

Embodiment 2

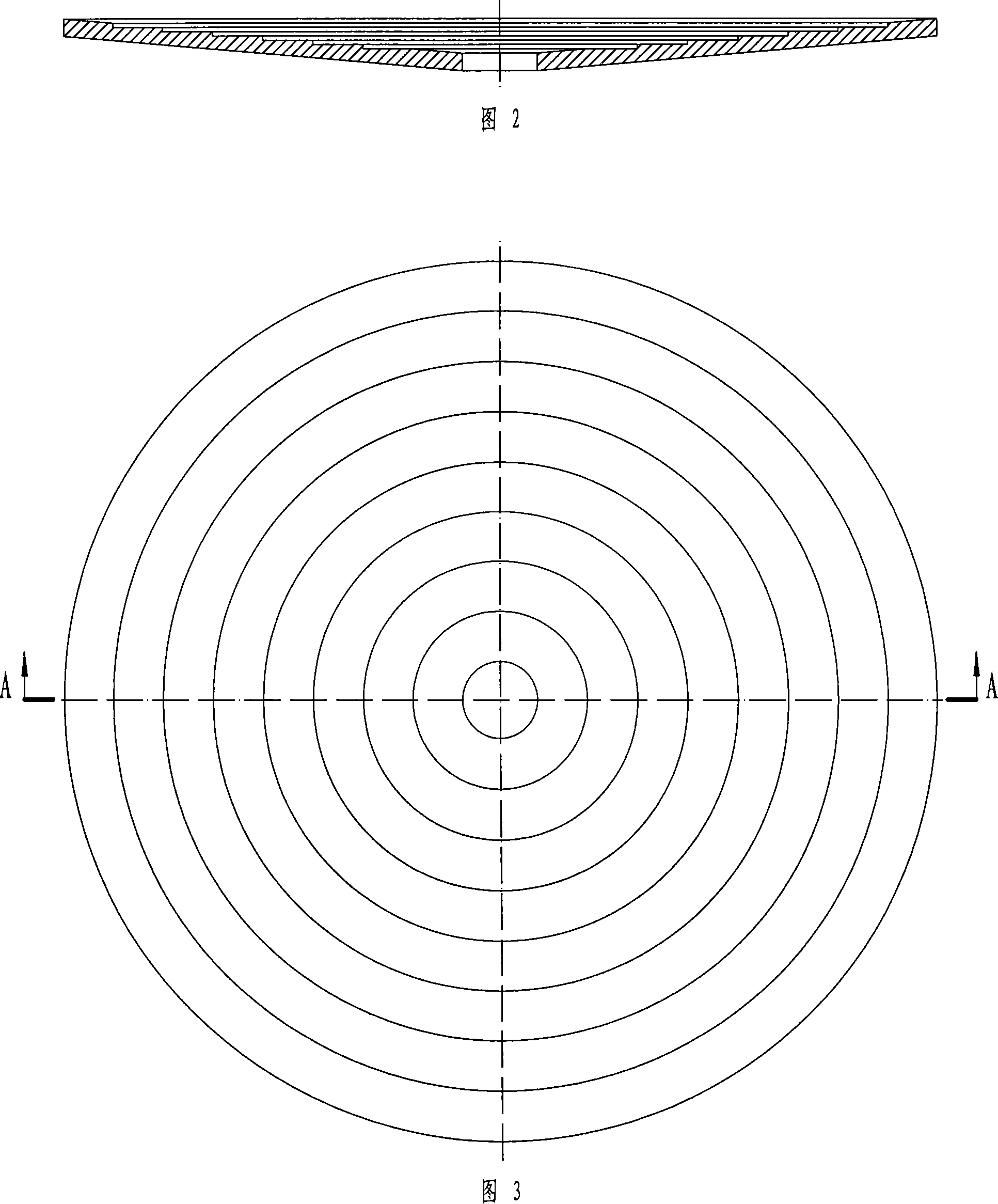

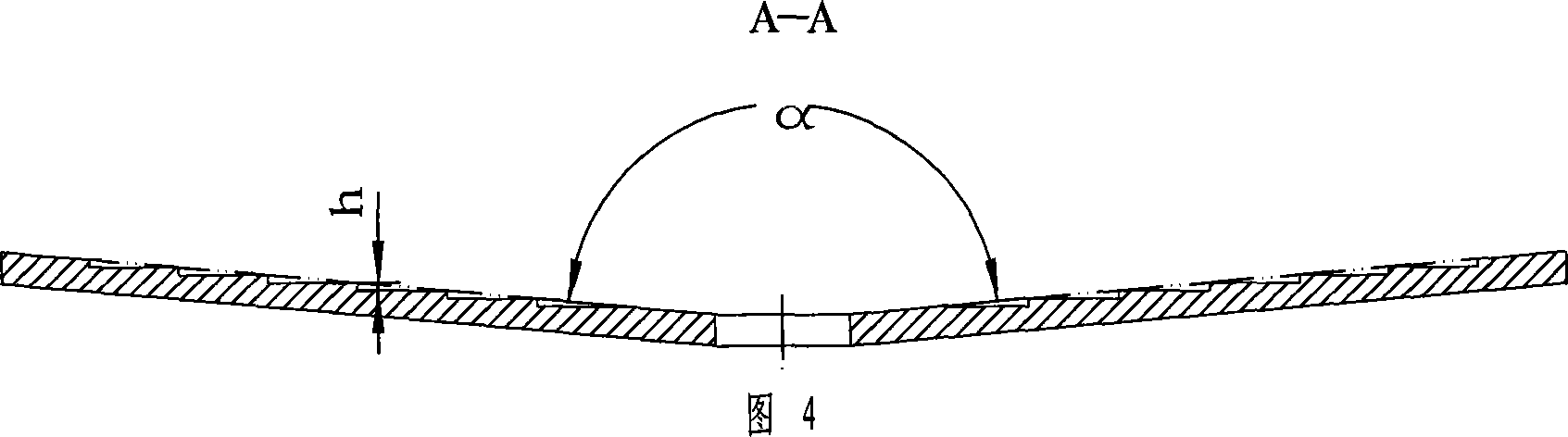

[0027] In this embodiment, the axial distance between the spreading disc 9 and the lower end of the retaining ring 12 is 2mm, the cone angle α of the inner surface of the spreading disc 9 is 120°, and the inner surface of the spreading disc 9 is processed with There are 10 concentric ring steps with different diameters connected to each other, and the axial height h between one ring step and the adjacent ring step is 0.5 mm. Other components and the coupling relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0029] In this embodiment, the axial distance between the spreading disc 9 and the lower end of the retaining ring 12 is 10mm, the cone angle α of the inner surface of the spreading disc 9 is 170°, and the inner surface of the spreading disc 9 is processed with There are 30 concentric ring steps with different diameters connected to each other, and the axial height h between one ring step and the adjacent ring step is 3 mm. Other components and the coupling relationship of the components are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com