Flushing and installing methods by using online raw liquor press pump under piping once

An installation method and hydraulic pump technology are applied to cleaning methods and appliances, chemical instruments and methods, and cleaning hollow objects, etc., which can solve problems such as waste of manpower, financial and material resources, hidden dangers to personal safety, and environmental pollution, and achieve cost savings, The effect of saving equipment costs and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

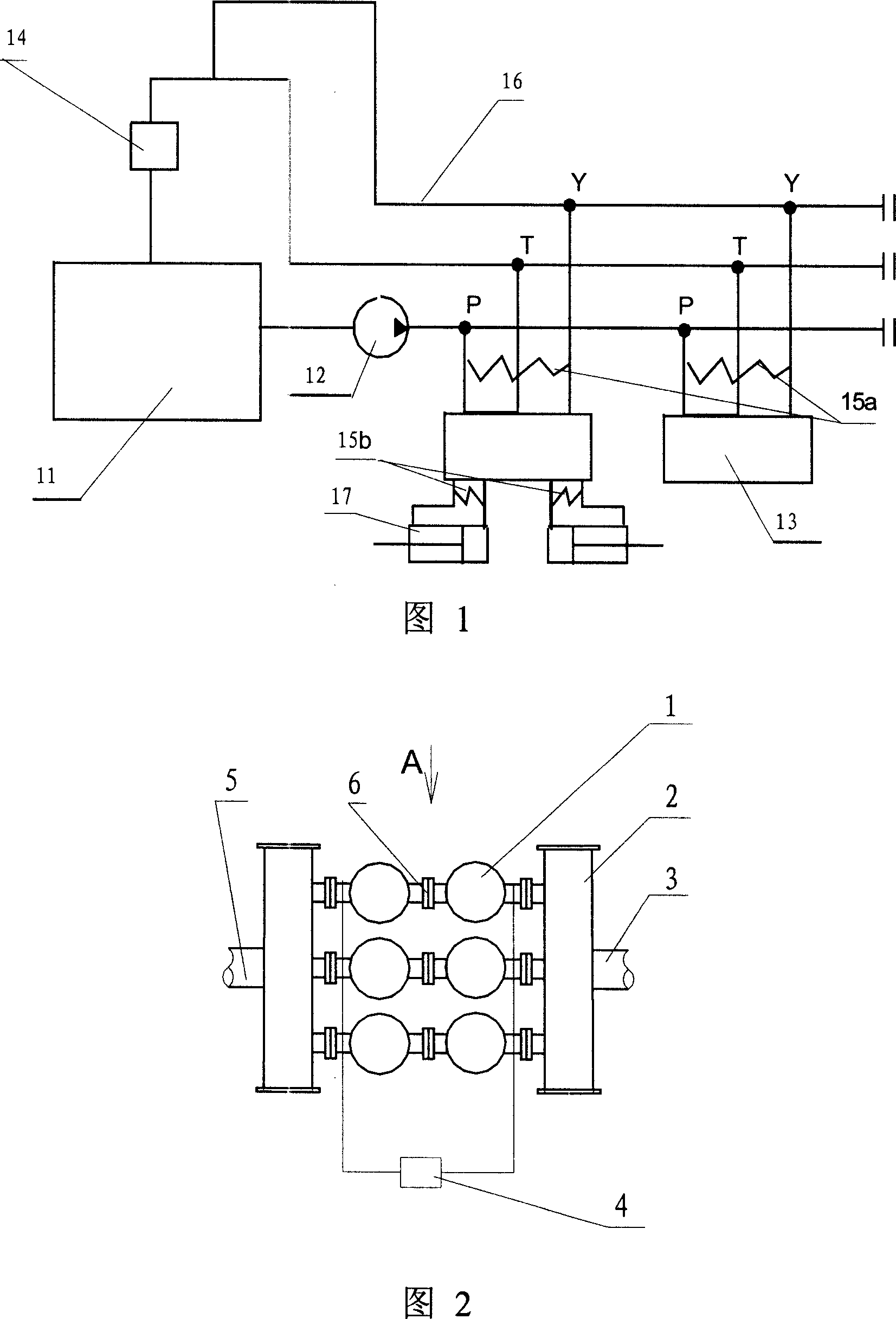

[0039] As shown in Figure 1, a hydraulic system primary piping, online use of the original hydraulic pump flushing installation method includes a fuel tank 11, hydraulic pump 12, oil pipe 16, valve frame 13 and oil cylinder 17, the hydraulic system primary piping, online original hydraulic pump The pump flushing installation method also includes a special hydraulic pump protection device 14, which is implemented according to the following steps:

[0040] 1) Oil pipe 16 pretreatment and installation connection

[0041] The oil pipe 16 is pretreated in a pickling factory, and the pretreatment includes pickling, passivation, drying, rust prevention, and packaging. After transporting the pretreated oil pipe 16 to the construction site, according to the design requirements of the hydraulic system, use the pretreated pipe to connect the hydraulic pump 12, the oil tank 11, the valve frame 13, and the oil cylinder 17 in order to form a circuit; at the same time, remove the filter and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com