Method for manufacturing side plate, back plate, and back base plate of refrigerator / ice-box

A processing method and technology of the rear bottom plate, applied in metal processing, application, household appliances, etc., can solve the problems of low strength, poor appearance performance of products, difficult to shape, etc., to reduce manufacturing costs, good molding effect and surface physical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

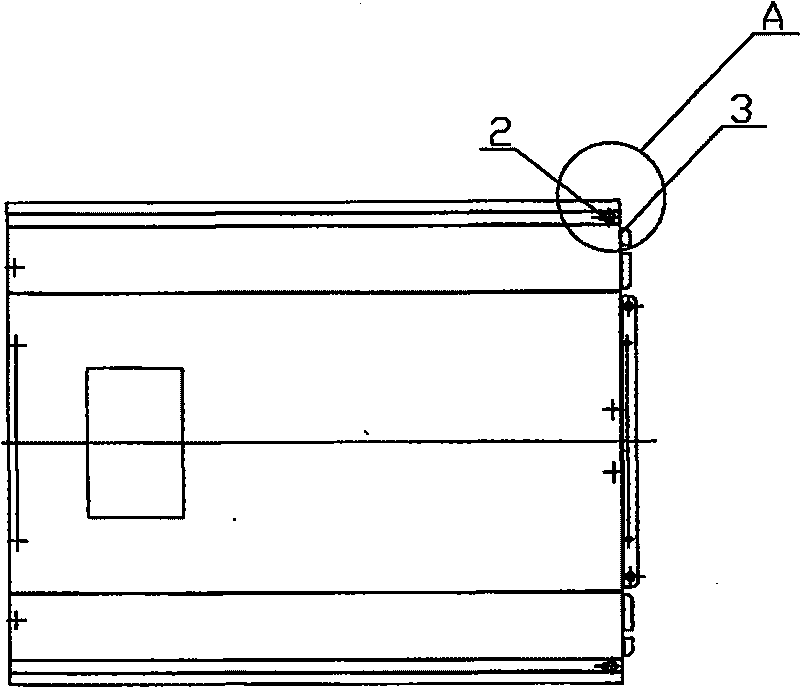

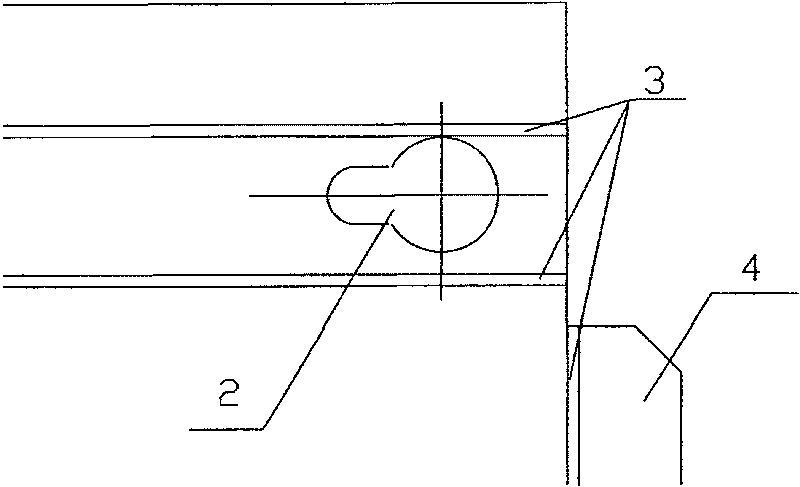

[0018] This embodiment takes the processing method of the rear plate of the refrigerator as an example.

[0019] A method for processing the rear panel of a refrigerator / freezer, using tough plastic materials such as PP, HDPE, ABS, HIPS, PVC, etc., and using a special surface treatment and molding method to prepare a new panel that meets the requirements of the refrigerator / freezer profiles.

[0020] The simple processing route of the side panel, rear panel and rear bottom panel of the refrigerator / freezer is: plastic pellets→extruded into plates, sheets and surface treatment→cutting→secondary processing and forming (including die stamping and bending forming)→ The surface is corona treated.

[0021] Select strong and tough plastic pellets, such as PP, HDPE, ABS, HIPS, PVC and other plastic pellets, to process the above plastic pellets. The specific steps are as follows:

[0022] (1) Extrude plastic pellets into plates, sheets and surface treatment, but usually for side pane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com