Non-linear rigidity vibration isolator for natural frequency of floating floorboard in high-speed vehicle

A natural frequency, nonlinear technology, applied in the field of nonlinear stiffness vibration isolators, can solve the problems of increase, large radiation noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

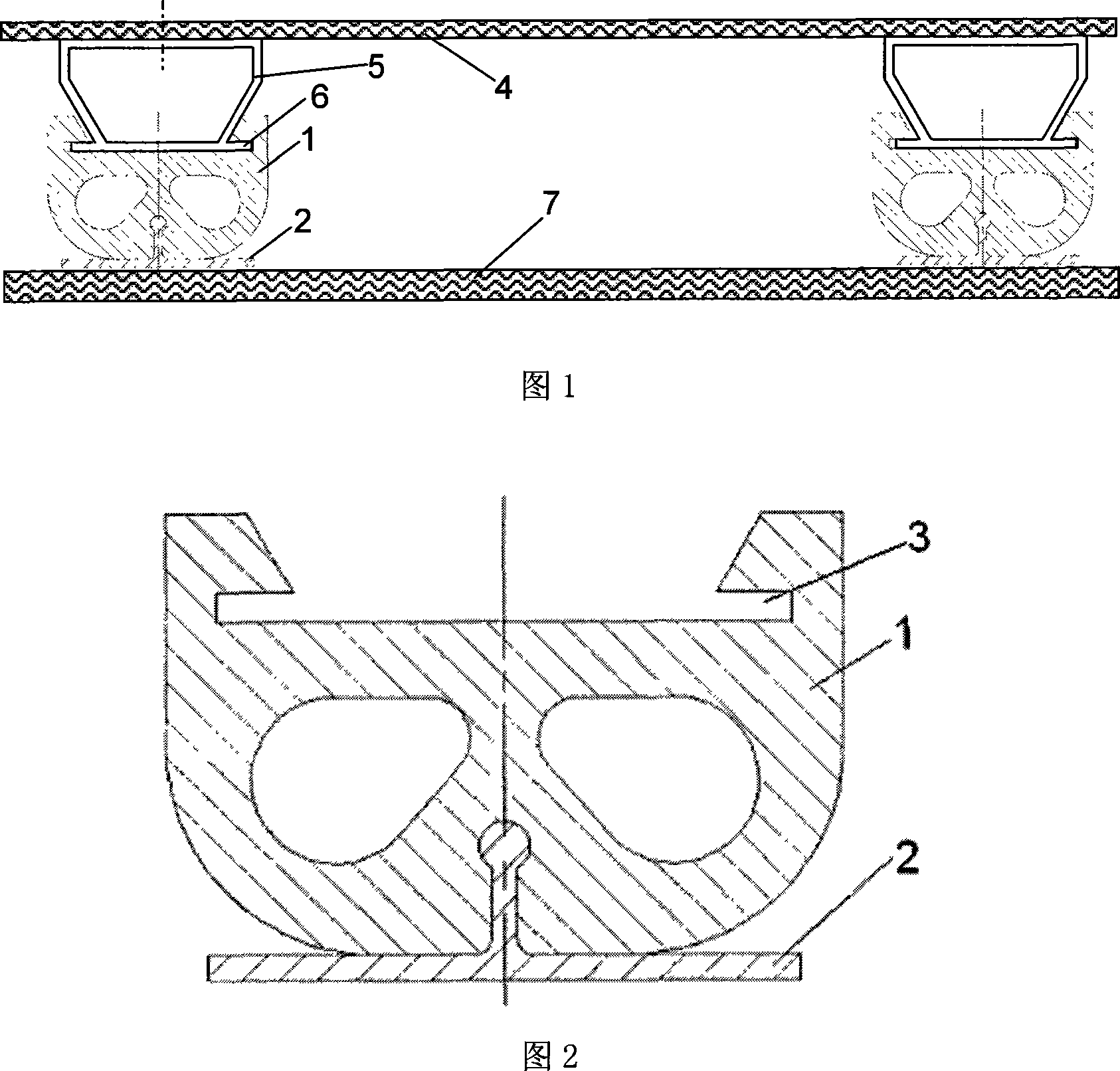

[0015] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

[0016] As shown in Figures 1 and 2, this embodiment is formed by vulcanizing the vibration-damping rubber 1 and the skeleton bottom plate 2, wherein the assembly notch 3 of the vibration-damping rubber 2 is used to cooperate with the support beam of the upper floor, so that the upper floor The support beam 5 of 4 can be snapped into the vibration isolator of the present invention, and the installation is convenient. Skeleton bottom plate 2 is special-purpose aluminum profile, and its top is a cylinder, and the bottom is an inverted T-shaped bar, and the two are integral and jointly formed. The lower bottom plate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com