Automatic air supply device for reducing cavitation vibration and noise of jet pump

A technology of automatic air replenishment and jet pump, which is applied in jet pumps, pumps, non-volume pumps, etc., to achieve the effects of reducing vibration and noise, high performance-price ratio, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Further illustrate below in conjunction with accompanying drawing and embodiment:

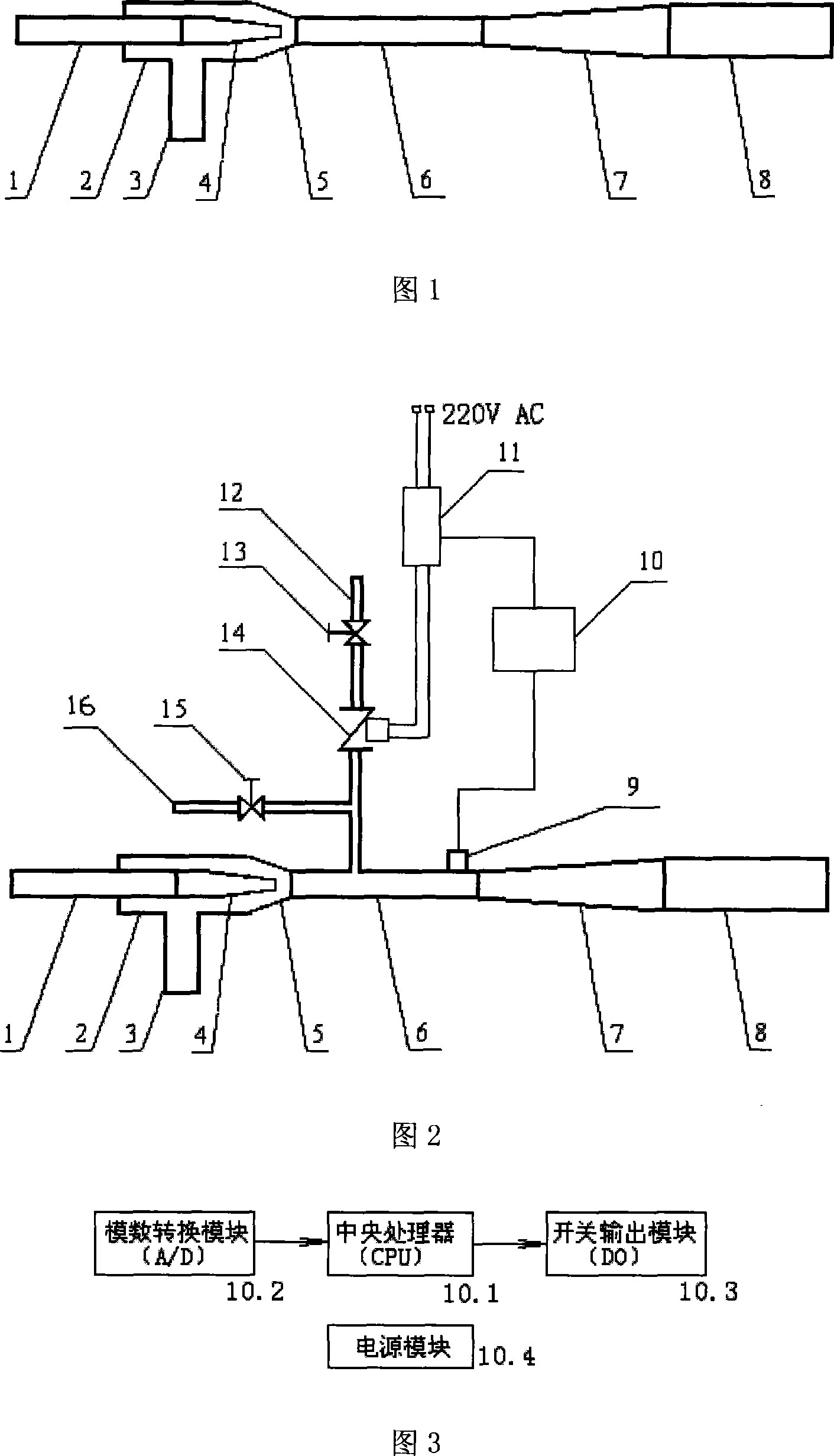

[0037] 1. Overall

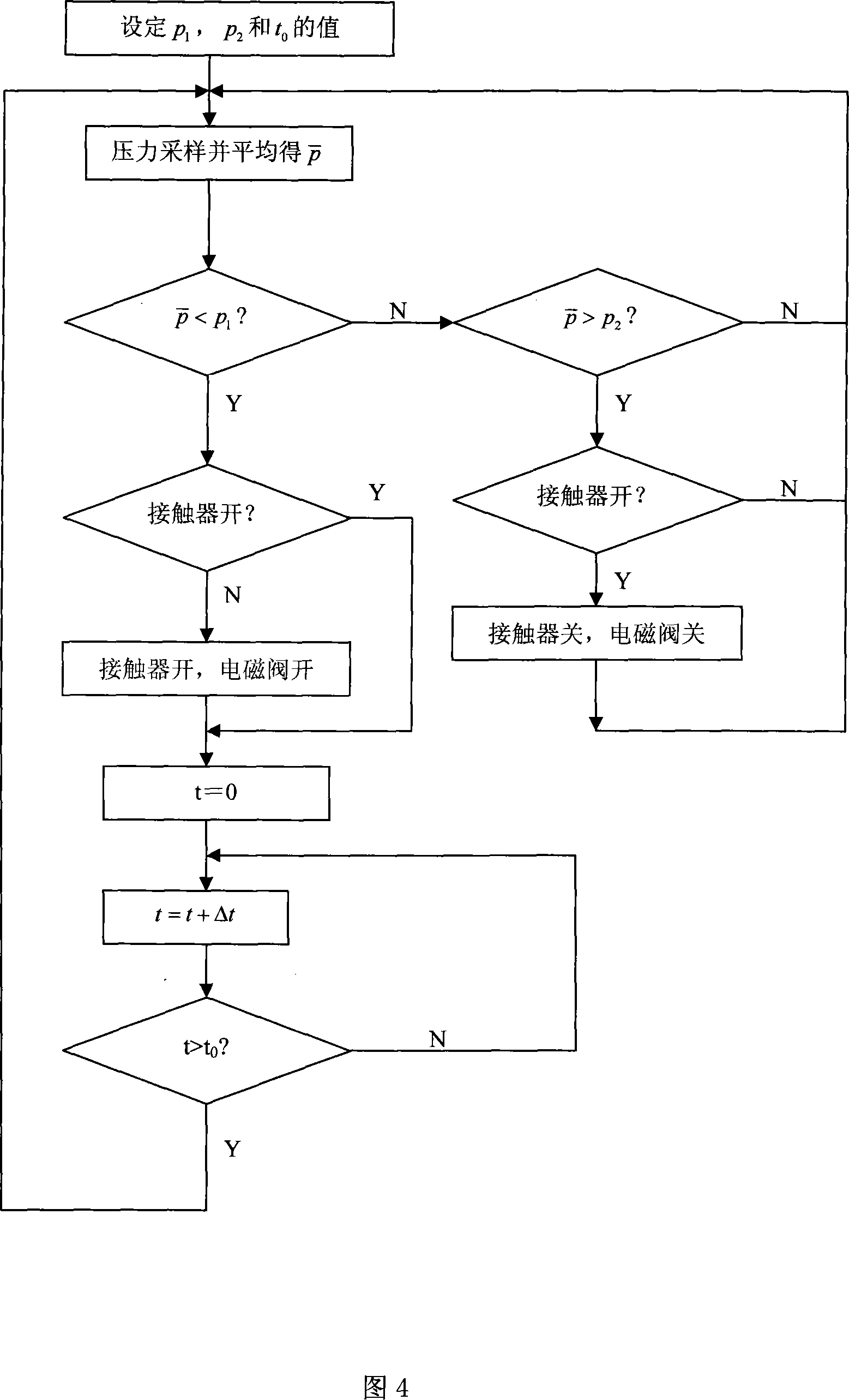

[0038] As shown in Fig. 2, the present invention is based on the conventional jet pump, and an automatic air supply device is set.

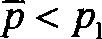

[0039] The automatic air supply device includes a pressure sensor (9), a PLC controller (10), a contactor (11), a main air intake pipe (12), a normally open valve (13), and a solenoid valve (14);

[0040] * On the main intake pipe (12), a bypass intake pipe (16) provided with a bypass valve (15) is connected through a three-way pipe. Once cavitation occurs in the jet pump, the 220V power supply loses power, or other failures occur, the solenoid valve (14) cannot be opened normally, and the outside air cannot be sucked by the main suction pipe (12), then the bypass valve (15) can be opened manually , outside air can also be sucked into the throat through the bypass pipe (16), thereby reducing the vibration and noise of the jet pump.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com