Heat radiation mechanism of soft starter for large current

A technology of soft starter and heat dissipation mechanism, applied in circuits, electrical components, electric solid devices, etc., can solve the difficulty of close contact between the busbar and the heat sink in a large area, the heat dissipation effect of the thyristor is not ideal, and the thyristor is easy to appear. Heat and other problems, to save money, improve the heat dissipation effect, and increase the contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

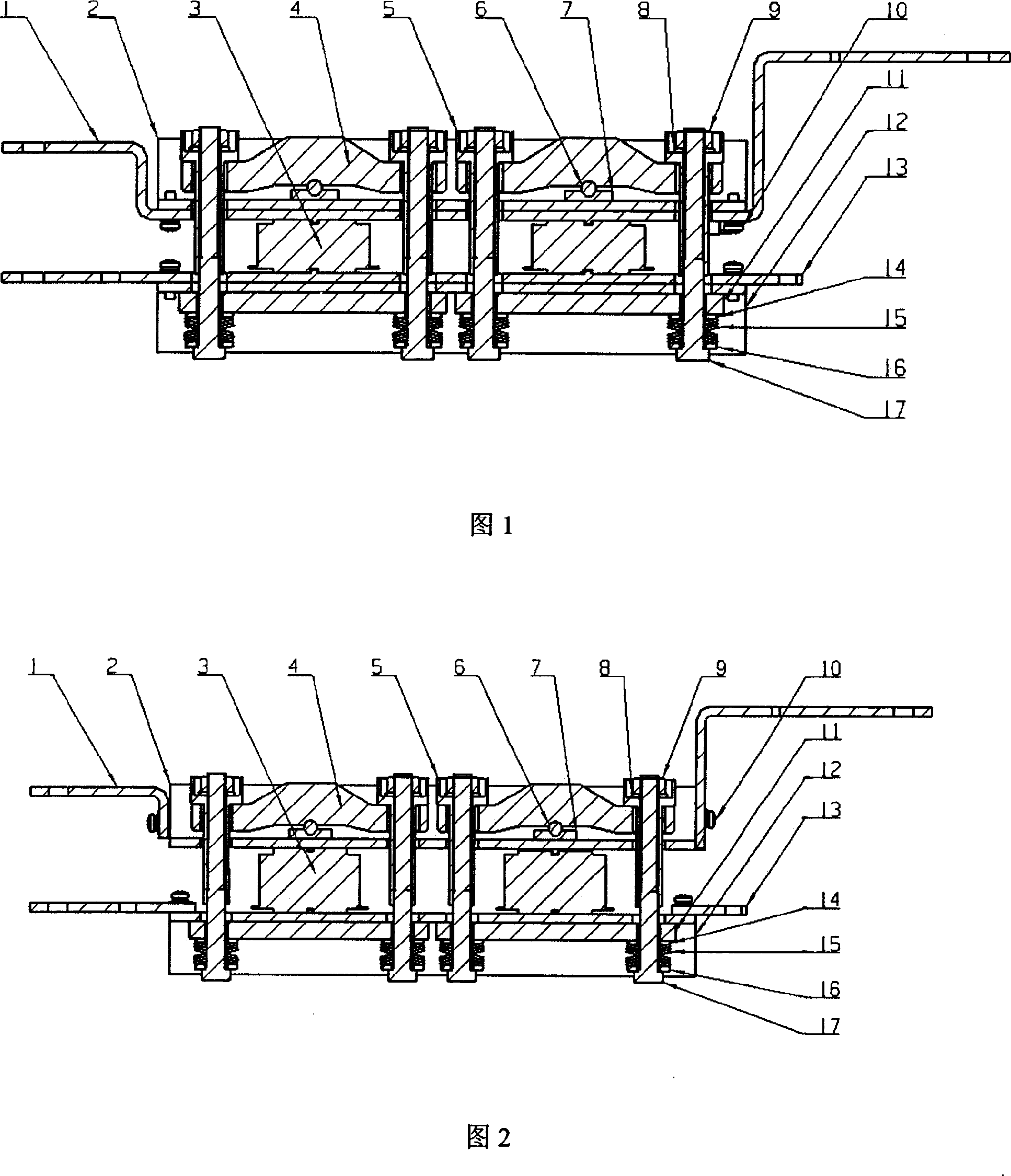

[0014] As shown in Figure 2, the high-current heat dissipation mechanism of the soft starter includes several thyristors 3, upper busbars 1, lower busbars 13, heat dissipation components, and connecting and fastening components. The row 1, the lower busbar 13, and the heat dissipation parts are connected and fastened by connecting and fastening parts. The heat dissipation parts include the upper heat sink 2 and the lower heat sink 12. The connection and fastening parts include bolts 17, washers 8, Washer 2 14, Washer 3 16, Disc washer 15, Nut 9, Screw 10, Upper platen 4, Lower platen 11, Backing plate 7, Bearing ball 6, Insulating bushing 5, said several SCRs 3 are directly tightened It is pasted between the upper heat sink 2 and the lower heat sink 12 .

[0015] There are two thyristors 3; the upper busbar 1 and the lower busbar 13 are respectively fixed in two sections o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com