Hot air engine used in car

A heat engine and automobile technology, applied to mechanical equipment, machines/engines, etc., can solve problems such as heat loss and complex structure, and achieve the effects of low consumption, low pollution, and high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

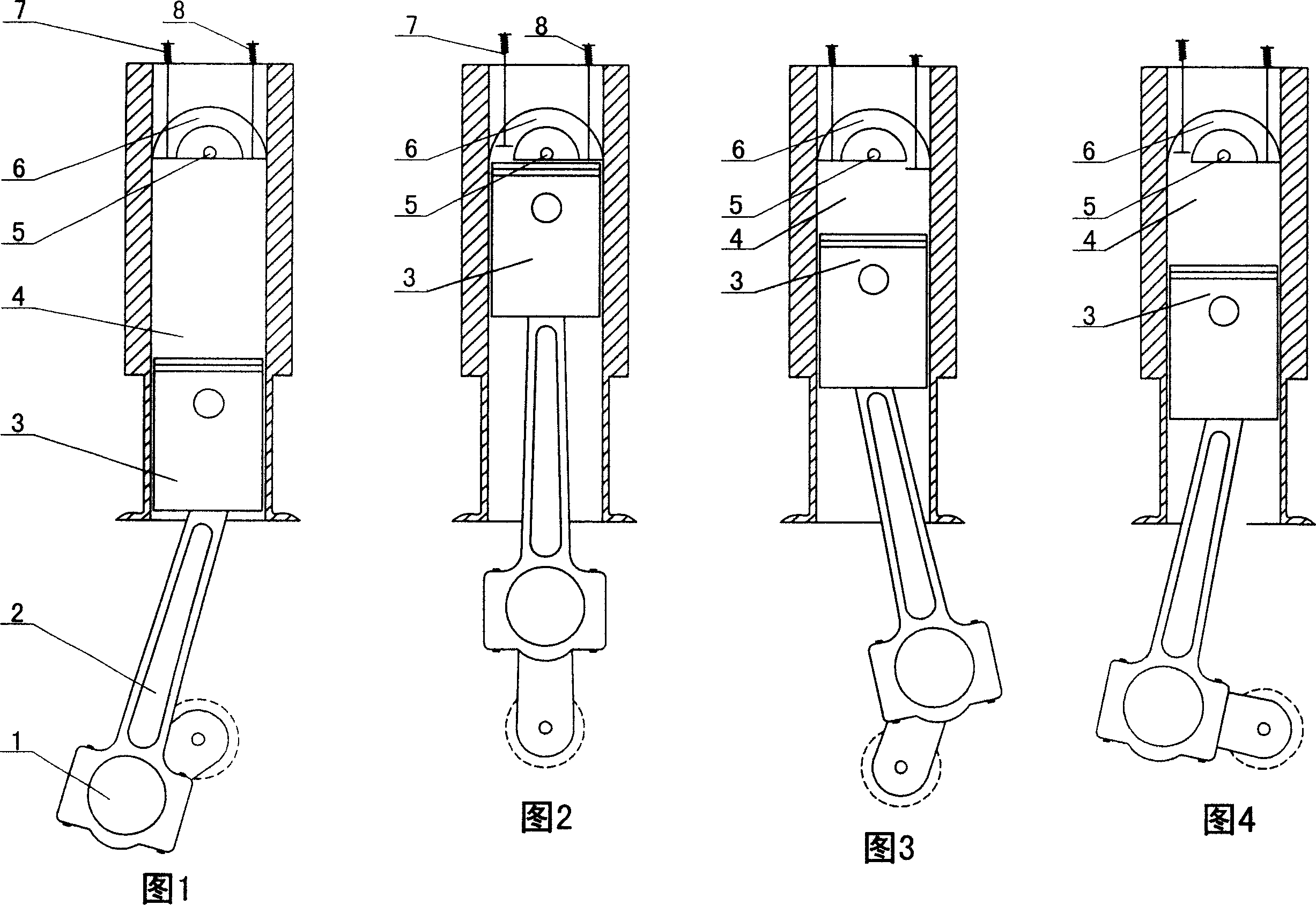

[0034] As shown in Figure 1, the engine starts to work, the flamethrower 5 ignites, the flame bakes the working gas passage 6, and the gas passage 6 and the cylinder 4 are filled with the working gas.

[0035] As shown in Figure 2, the exhaust valve 7 is opened, the intake valve 8 is closed, and the starter rotates the flywheel (driven by the inertia of the flywheel after starting) through the crankshaft 1 and the piston 3 is retracted to the top dead center, and the gas in the cylinder 4 It is pushed from the exhaust valve 7 into the working gas passage 6 and conducts heat transfer with the air passage wall whose temperature is as high as 1000°C, so that the temperature and pressure of the recompressed gas rise to the maximum value instantaneously.

[0036] As shown in Figure 3, after the piston 3 reaches the top dead center, the exhaust valve 7 is closed and the intake valve 8 is opened. The high-pressure gas enters the cylinder 4 and expands, pressing the piston 3 downward, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com