Feed nozzle assembly and burner apparatus for gas/liquid reactions

A technology for feeding nozzles and components, which can be used in gas fuel burners, chemical/physical/physical-chemical nozzle reactors, burners, etc., and can solve problems such as clogging equipment and shortening burner life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

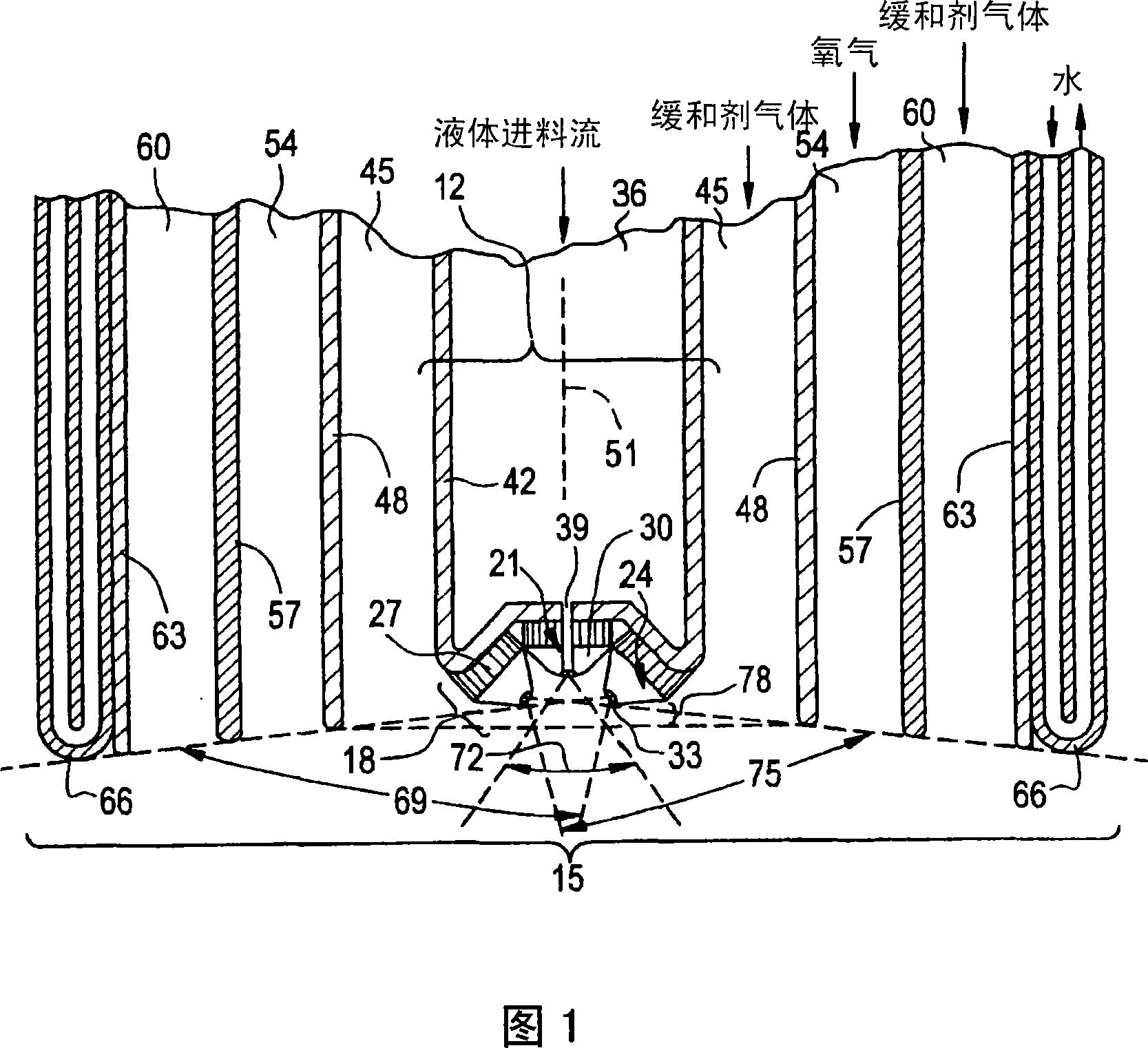

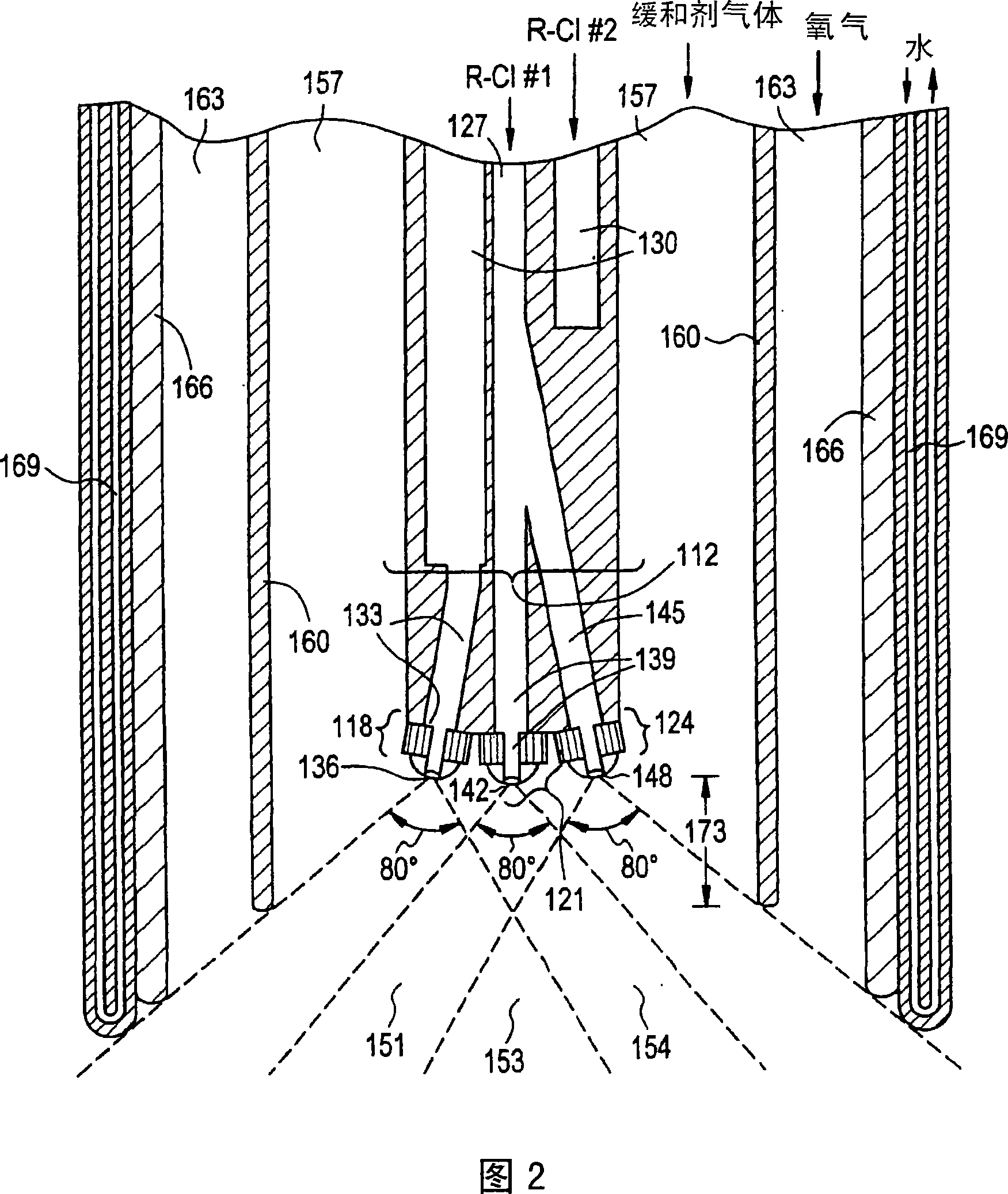

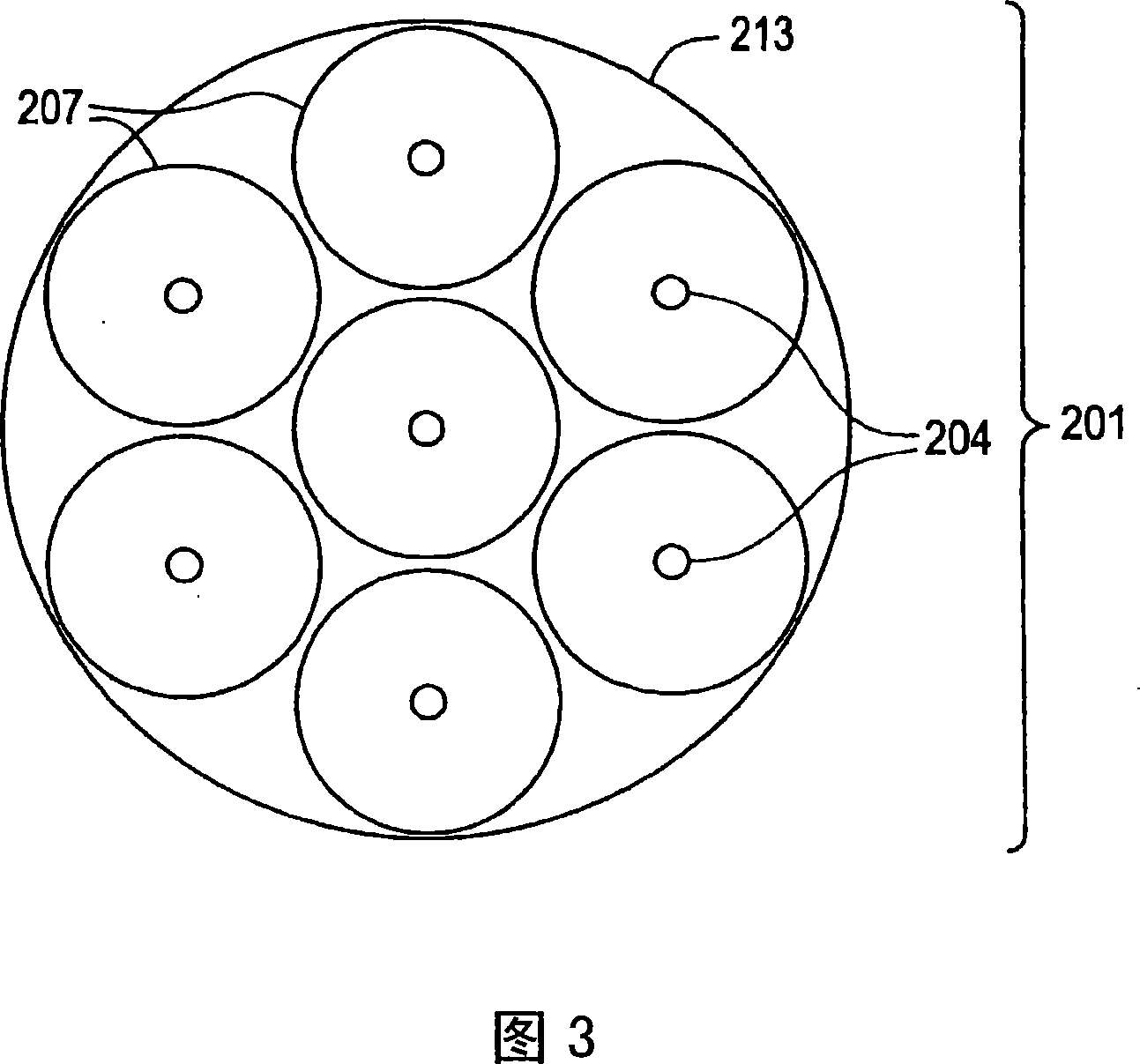

[0018] The feed nozzle assembly of the present invention is a simple but extremely effective means of preventing the problems associated with the use of only one feed nozzle, while surprisingly, teaching throws aside the accepted knowledge that "spray" is atomized. Convergence of the liquid feed stream is unacceptable and automatically increases the size of the droplets, improving poor conversion and overall process performance. It has now been found that by suitably adjusting the number of feed nozzles and their positioning relative to each other, and taking into account the characteristics of each feed nozzle with respect to maximum feed velocity, hole configuration and ultimately spray pattern, the spray can be The impingement is done in such a way as to balance the impact breakage and coalescence of the droplets to ensure the desired droplet size for a given operation while maximizing the potential feed stream input rate.

[0019] Impact obviously requires at least two spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com