Large vertical shaft hammering type crusher

A crusher and vertical shaft technology, which is applied in the field of large vertical shaft hammer crushers to achieve good crushing effect, prevent clogging and increase the discharge rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

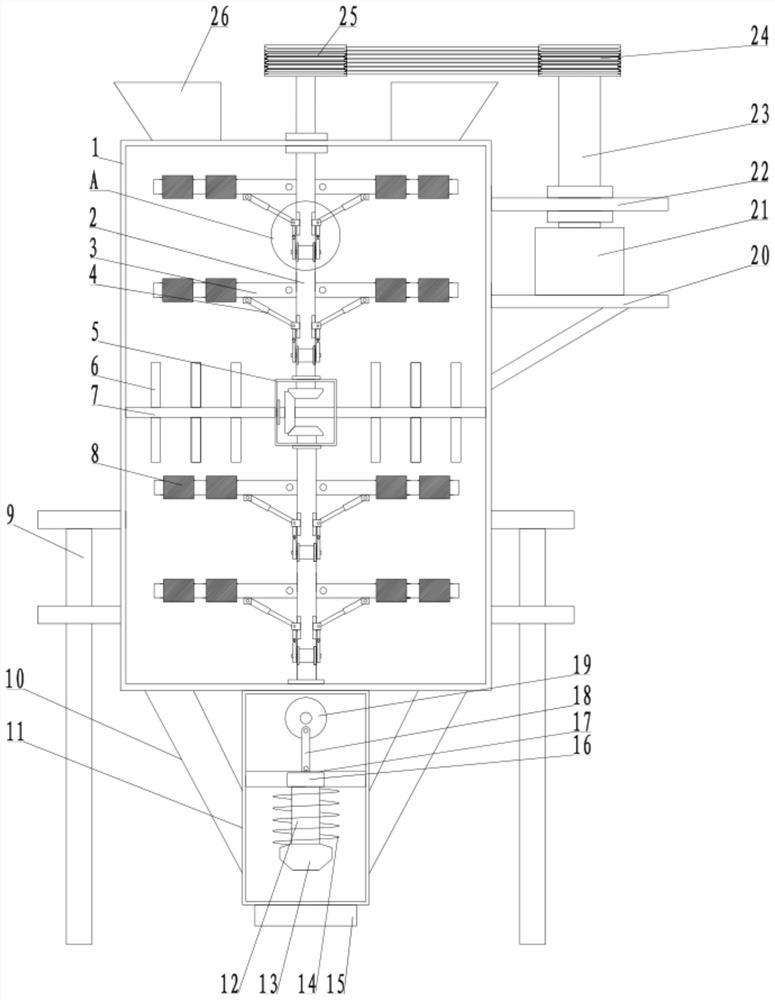

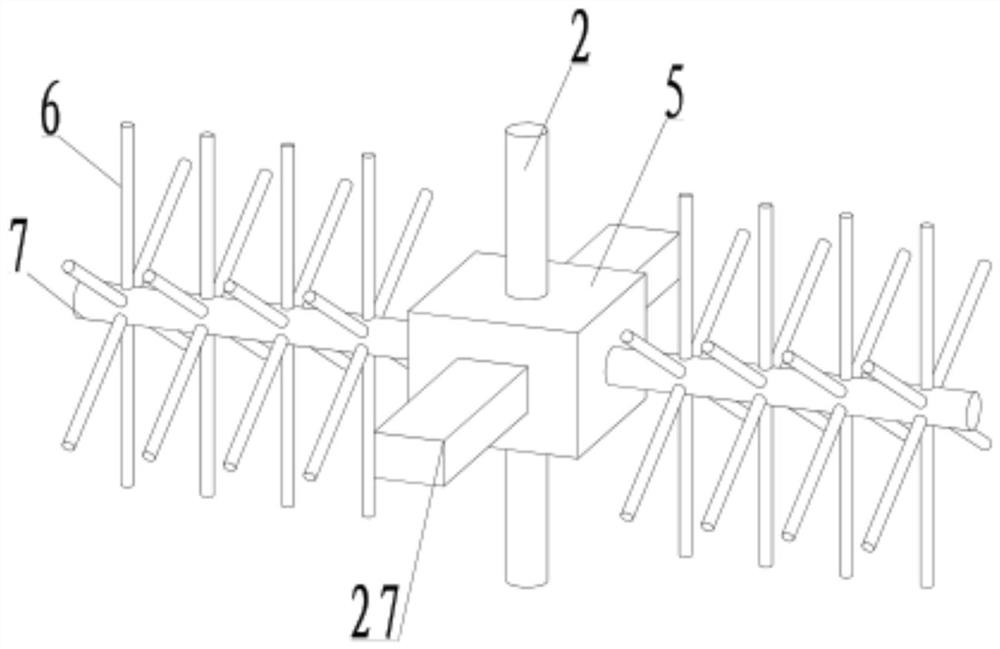

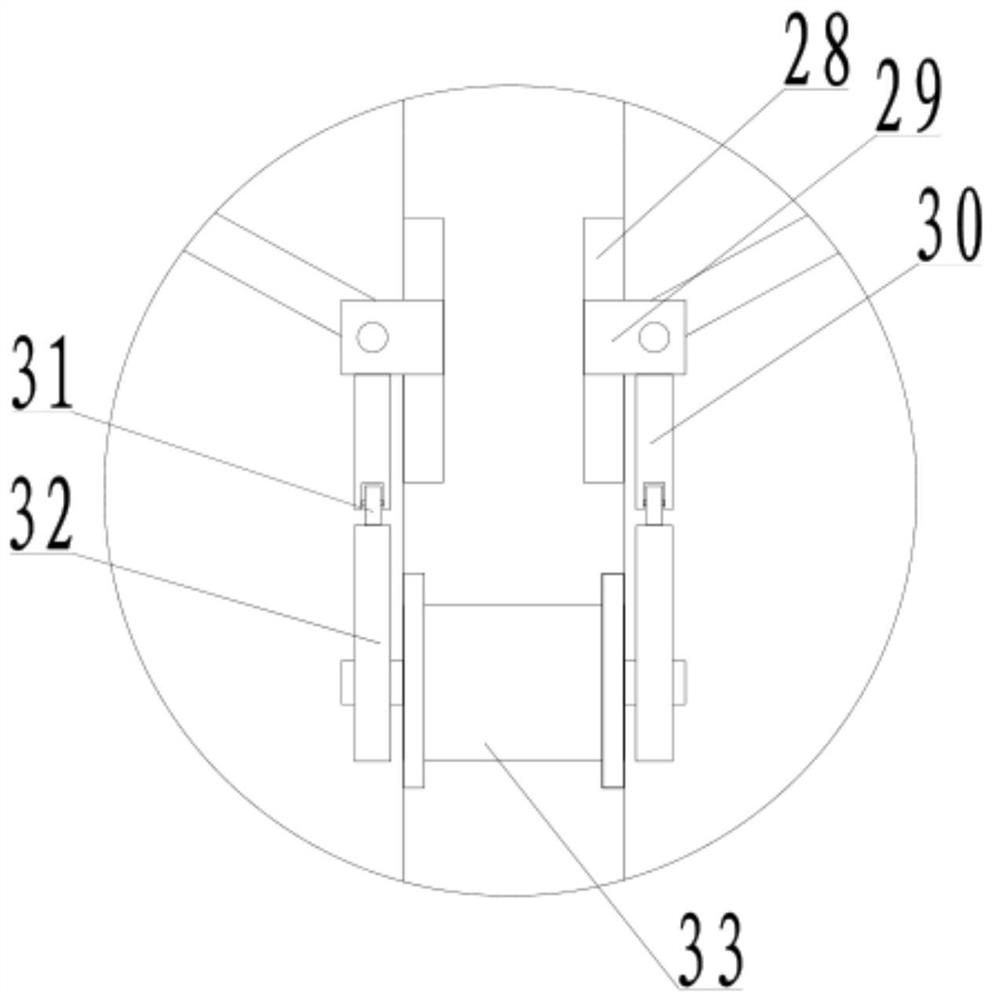

[0021] see Figure 1-4 , a large vertical shaft hammer crusher, comprising a crushing box 1, a transmission box 5 is arranged in the crushing box 1, the front and rear sides of the transmission box 5 are fixedly connected with installation rods 27, and the two sides of the installation rod 27 are connected to the front and rear of the crushing box 1. The side walls are fixedly connected, the top and bottom of the transmission box 5 are rotatably connected to the rotating column 2, the two sides of the rotating column 2 are hingedly connected to the crushing rod 3, and the crushing rod 3 is fixedly connected to the crushing hammer 8 on the side away from the rotating column 2, and the crushing rod 3 The bottom is hingedly connected to the elastic telescopic rod 4, and one side of the rotating column 2 below the elastic telescopic rod 4 is provided with a chute 28, and the mounting block 29 is slidably connected on the chute 28, and one side of the mounting block 29 is hingedly c...

Embodiment 2

[0027] see Figure 1-4 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the two ends of the crushing column 7 pass through the side wall of the transmission box 5, extend to the side wall of the crushing box 1, and both sides are connected to the side wall of the crushing box 1 Rotationally connected, the crushing columns 7 on both sides of the transmission box 5 are fixedly connected to the crushing blades 6 .

[0028] In the implementation process of the present invention, the material is put into the crushing box 1 from the feed pipe 26, the drive motor 21 is started, and under the action of the belt, the rotating column 2 is driven to rotate. Driven by the cam 32 on the motor 33, the installation block 29 moves back and forth in the chute 28, and then drives the elastic telescopic rod 4 to move, and the crushing hammer 8 swings in a small range. When crushing, the flexibility of the device is increased, and the crushing ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com