Heat sink and cooling unit using same

A technology of heat dissipation device and cooling unit, which is applied in cooling/ventilation/heating transformation, electrical components, electric solid devices, etc., can solve the problems of increasing temperature difference of heating element mounting surface, increasing volume of heat dissipation device, and high temperature of cooling fluid , to achieve the effect of excellent thermal uniformity and compact thermal uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Implementation form 1.

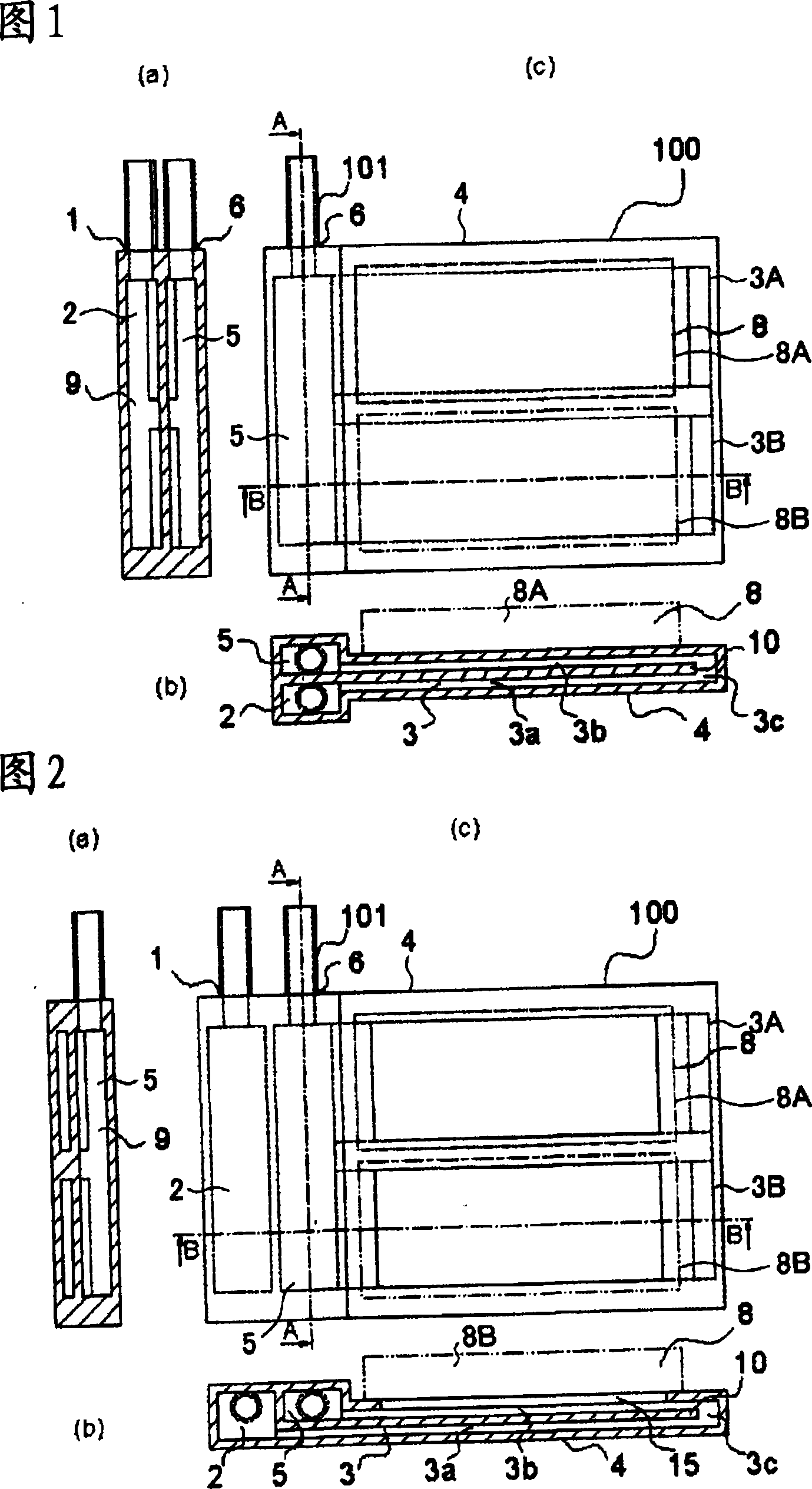

[0039] Fig. 1 is a structural diagram schematically showing a heat dissipation device according to Embodiment 1 of the present invention, Fig. 1(c) is a diagram seen when observing the heat dissipation device from above, Fig. 1(a) is a diagram in Fig. The sectional view at the line A-A in Fig. 1(b) is the sectional view at the line B-B in Fig. 1(c). In addition, Fig. 2 is a diagram showing another structure of the heat sink according to Embodiment 1 of the present invention, Fig. 2(c) is a diagram seen when the heat sink is viewed from above, Fig. 2(a) is a 2(c) is a sectional view at the line A-A, and FIG. 2(b) is a sectional view at the line B-B in FIG. 2(c).

[0040]In FIGS. 1 and 2 , the heat sink 100 constitutes a cooling system for cooling the heat generating element 8 mounted thereon. The cooling device 100 is composed of the following parts to form a serial flow path: the cooling fluid inlet 1 for sending in the low-temperature cooling...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap