Stream catapult for aircraft carrier based airplane

A technology for aircraft carriers and carrier-based aircraft, applied in the direction of launching/dragging transmissions, etc., can solve the problems of shortened ejection time, no energy buffer, and large maintenance, and achieve the effect of reducing launch costs, low cost, and low maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

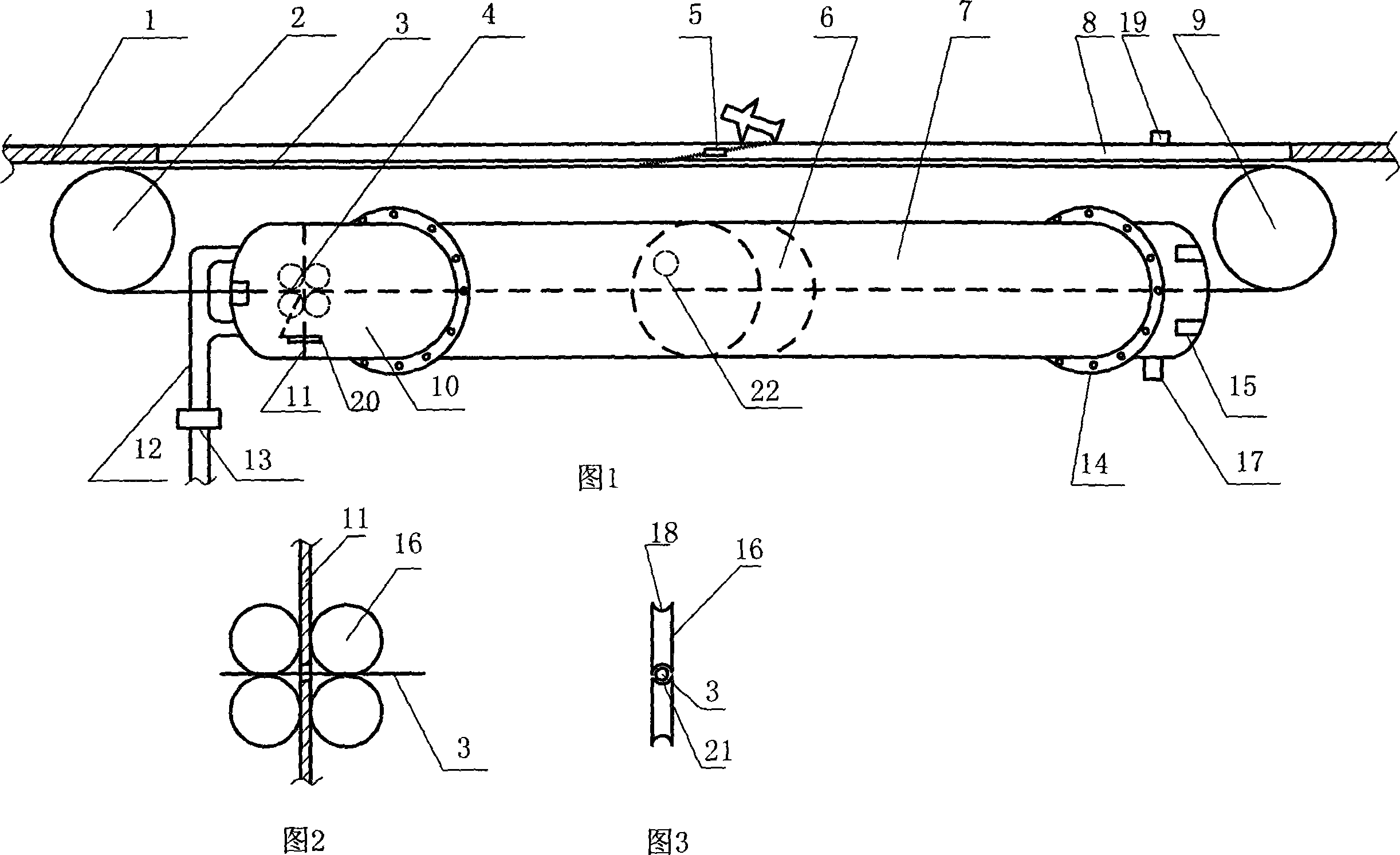

[0012] The present invention will be further introduced below in conjunction with the drawings and specific embodiments, but it is not intended to limit the present invention.

[0013] As shown in Figure 1, a steam catapult for an aircraft carrier carrier aircraft includes an aircraft carrier ship deck 1, a program control system, a launch system, and a sealing lubrication system 4. The launch system includes a long guide groove 8 opened at the tail of the ship deck 1. The guide groove 8 is the steam catapult track, in which there is a sliding block 5, a sliding block 5 moving along the guide groove 8, and one end of the sliding block 5 is connected to an annular steel cable 3 that can move in a circular motion. Surrounded on the front fixed supporting wheel 2 and the rear fixed supporting wheel 9 arranged along the guide groove 8 arranged in the ship cabin, the high-pressure sealed cylinder 10 is fixed on the ship body through a bracket (not shown in the figure). Below the circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com