Yellow reactive dye composition and application thereof

A dye composition and reactive dye technology, applied in the directions of organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems of color yield, dye uptake compatibility and compatibility to be further improved, and achieve dyeing reproduction. Good properties, bright color and good fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The preparation method of the yellow reactive dye composition of the present invention comprises mixing the above-mentioned dye I: dye II according to a prescribed weight ratio. Various conventional methods can be used for mixing, such as mechanical mixing methods. When mixed, dye I and dye II may be present in powder form, or in granular form, or in aqueous solution.

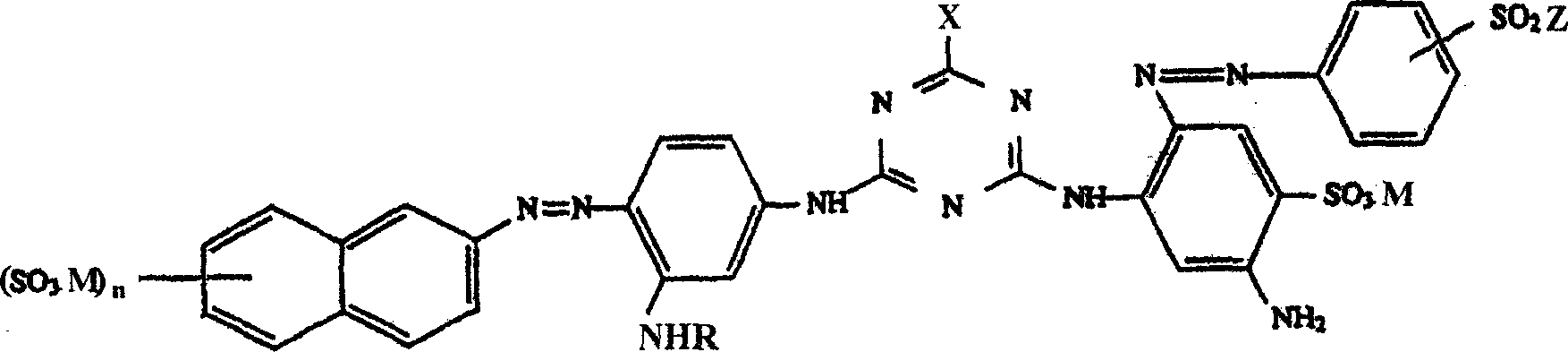

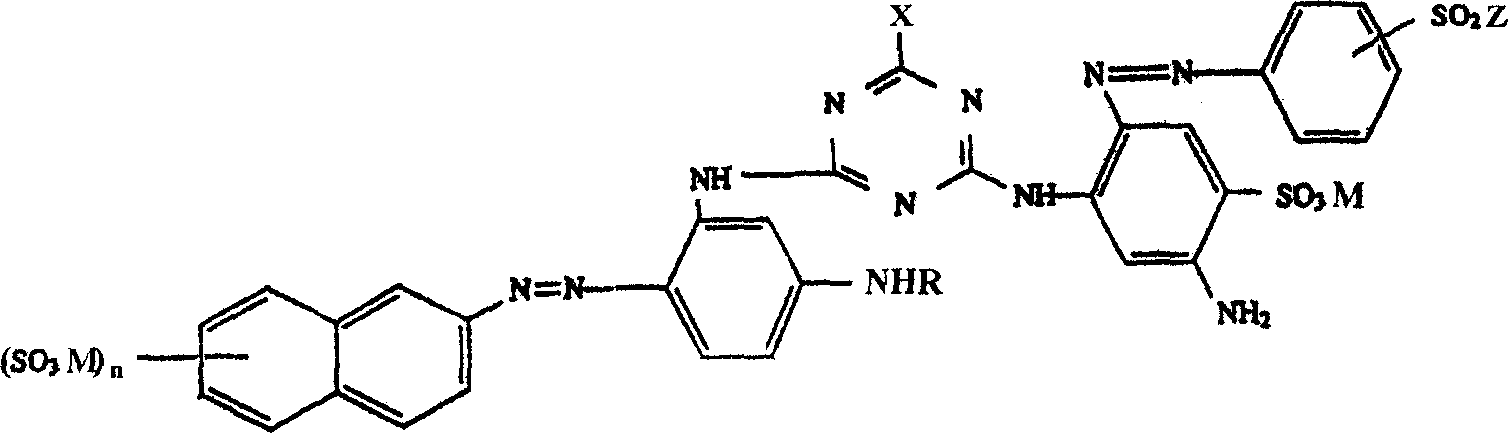

[0056] Dye I can be purchased from the market as a known yellow reactive dye (trade name: reactive yellow SHE, Jiangsu Shenxin Dyestuff Chemical Co., Ltd.), and can also be prepared according to known methods. For example, its preparation method has been specifically described in US 5,484,899 (1996) and CN 1569969 (2005) (incorporated herein as a reference), including:

[0057] a) Make 2-naphthylamine-di- or trisulfonic acid diazonium salt and an amino group -CONR a R b or -COR a (R a and R b The protected m-phenylenediamine or its derivatives having the above-mentioned meanings) are coupled under ...

preparation Embodiment 1

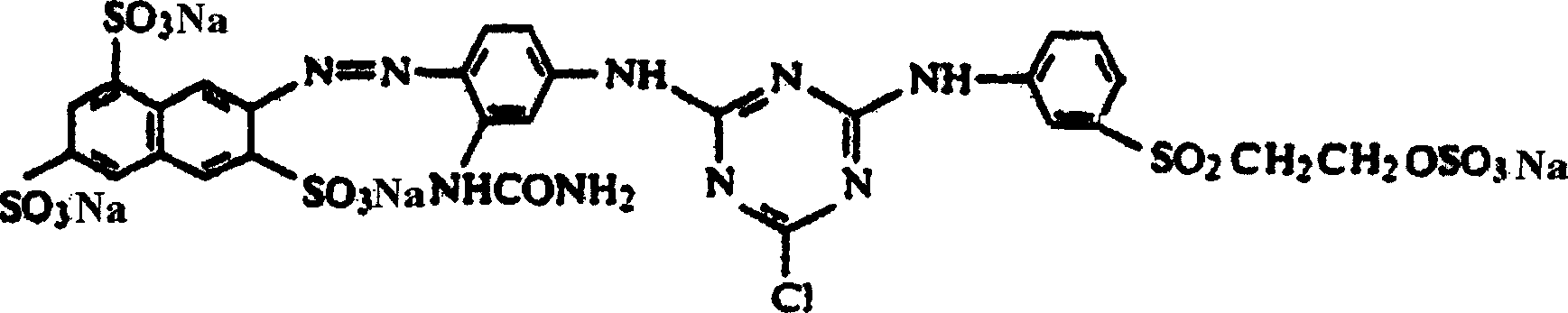

[0067] Dye I represented by the formula 1 preparation of

[0068] Dye I was prepared according to the method specified in US 5,484,899 (1996) 1 , There is a maximum absorption peak at a wavelength of 425nm in the UV absorption curve measured by UV spectroscopy.

[0069] Dye I 1

[0070]

preparation Embodiment 2

[0072] Dye I represented by the formula 2 preparation of

[0073] Dye I was prepared by the method of Preparation Example 1 1 During the process, at the end of the reaction, the dye I 1 Continue the reaction at 40-50°C for 1-2 hours under the condition of pH 8-9 to obtain dye I 2 . In the UV absorption curve measured by UV spectrum, there is a maximum absorption peak at a wavelength of 418nm.

[0074] Dye I 2

[0075]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com