Plasma semi-additive process method for manufacturing pcb

A circuit substrate and plasma technology, which is applied in the fields of printed circuit manufacturing, printed circuit, printed circuit secondary treatment, etc., can solve the problems of high developing failure rate and decreased adhesion of plating, etc., and achieve the effect of minimizing process failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

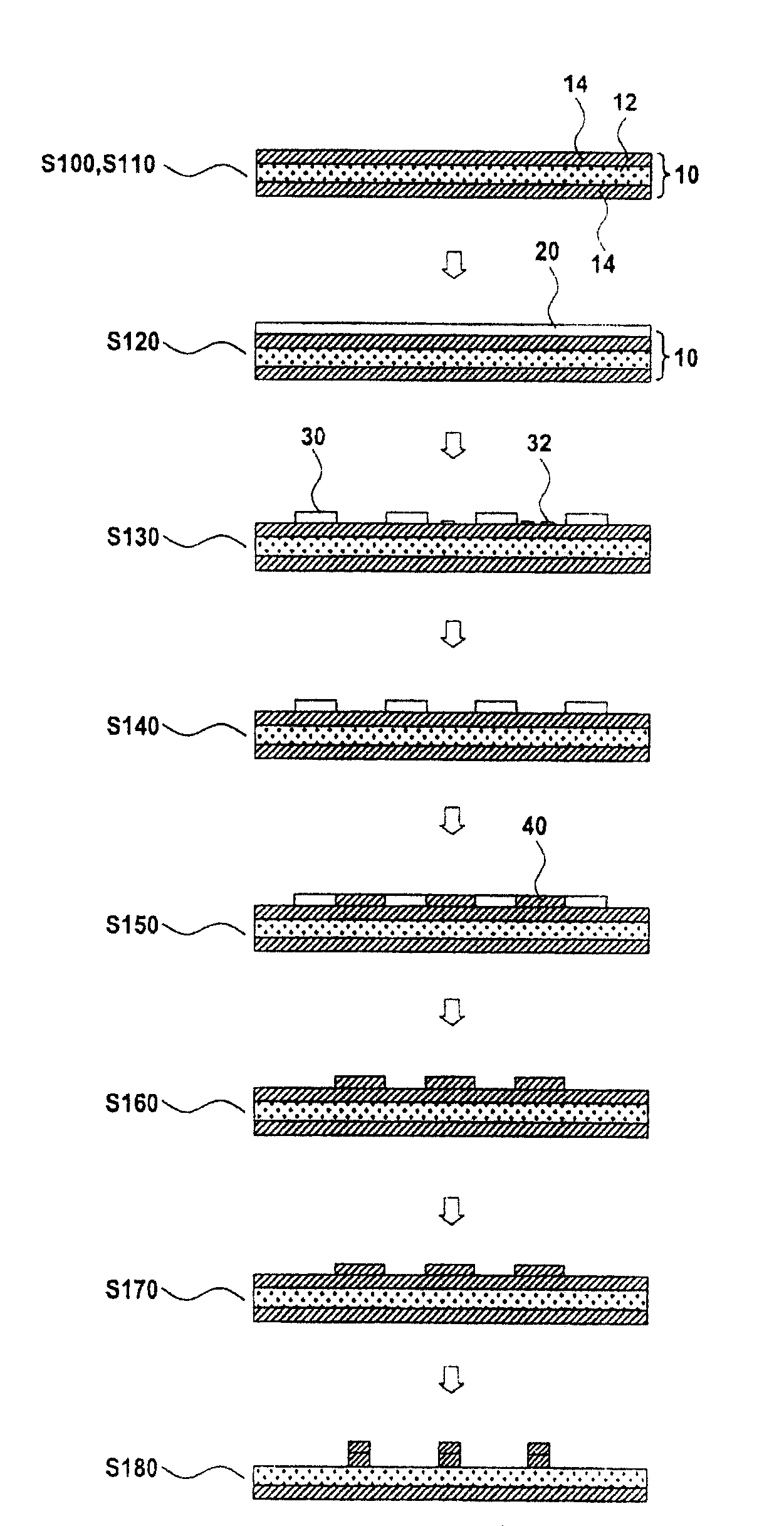

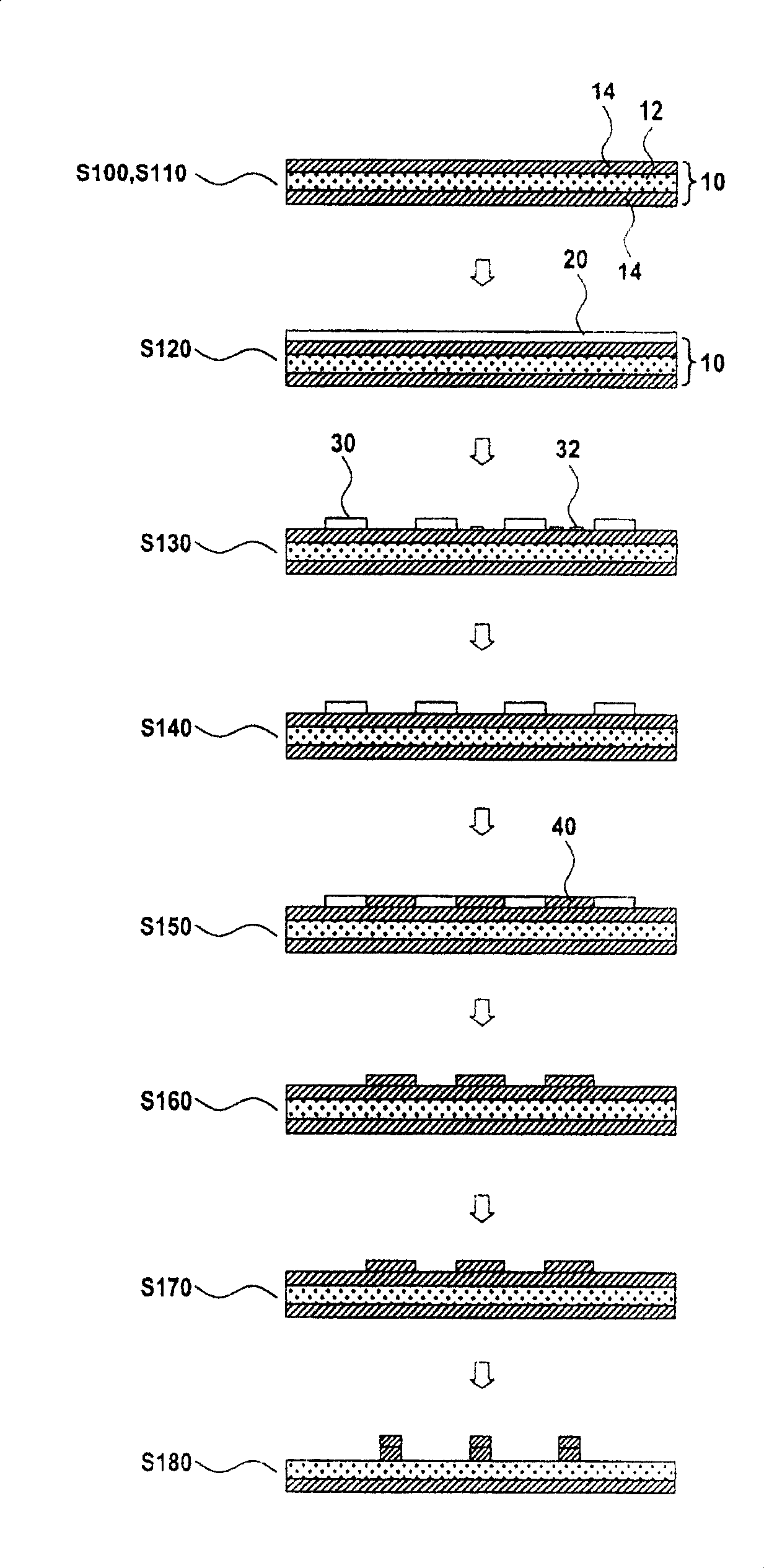

[0023] Hereinafter, preferred embodiments of the present invention will be described in more detail with reference to the drawings. figure 2 is a process diagram showing the PSAP method according to the present invention.

[0024] like figure 2 As shown, the PSAP process for manufacturing the printed circuit board involved in the present invention roughly includes a base substrate preparation stage (S100), a first plasma treatment stage (S110), and photoresist (photo resist) formation. stage (S120), pattern forming stage (S130), second plasma processing stage (S140), line forming stage (S150), first etching stage (S160), third plasma processing stage (S170) and second etching stage (S180).

[0025] In the base substrate preparation step ( S100 ), a double sided copper clad laminated board (double sided copper clad laminated: CCL) ( 10 ) is used as the base substrate.

[0026] The above-mentioned laminate (CCL) (10) has copper foil on both surfaces of the plate-shaped subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com