Steel plate mark printer

A printer and marking technology, used in typewriters, printing and other directions, can solve the problems of no steel plate marking printing equipment, can not be used for reference and inspection, difficult to achieve automatic printing, etc. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

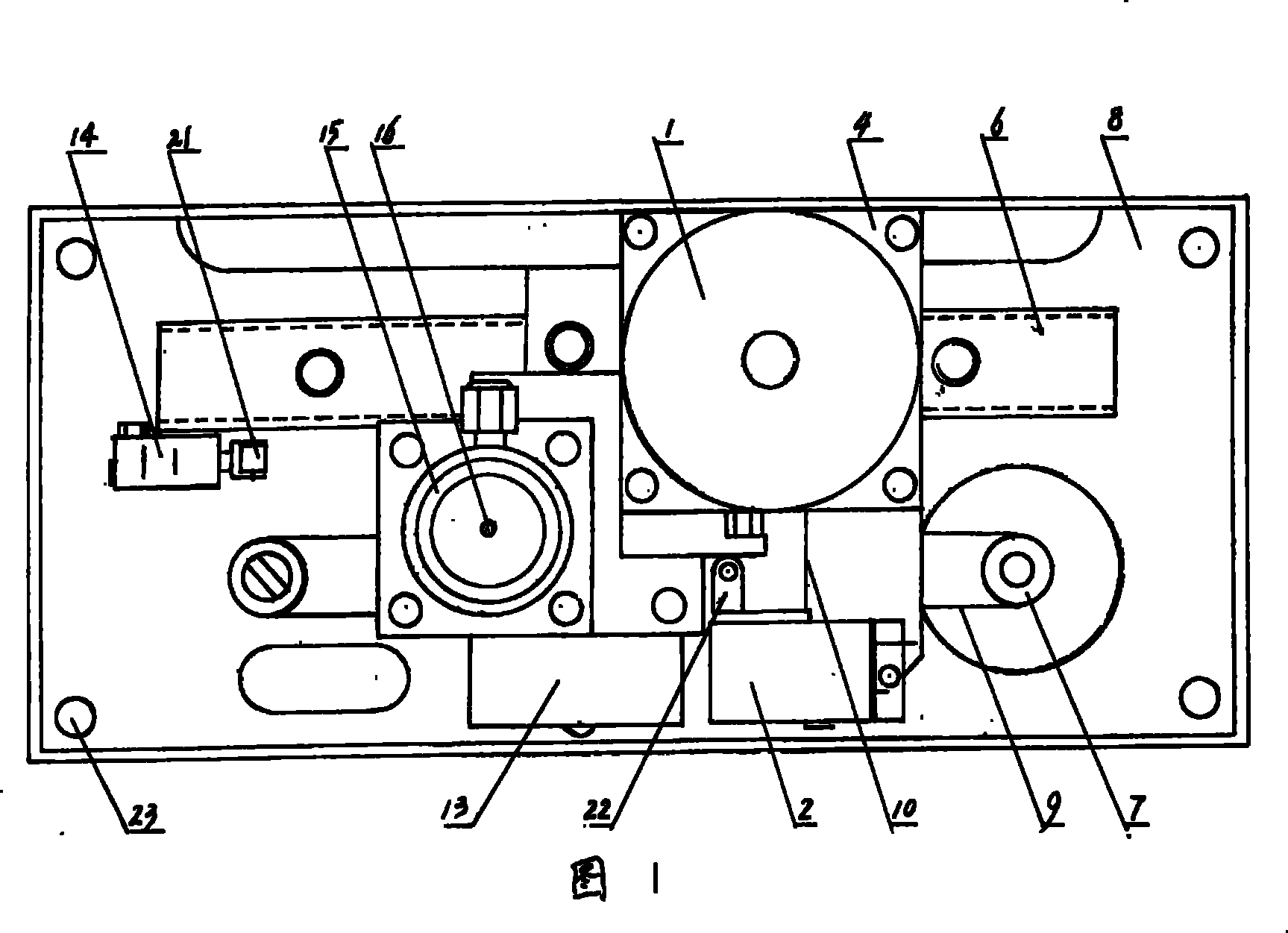

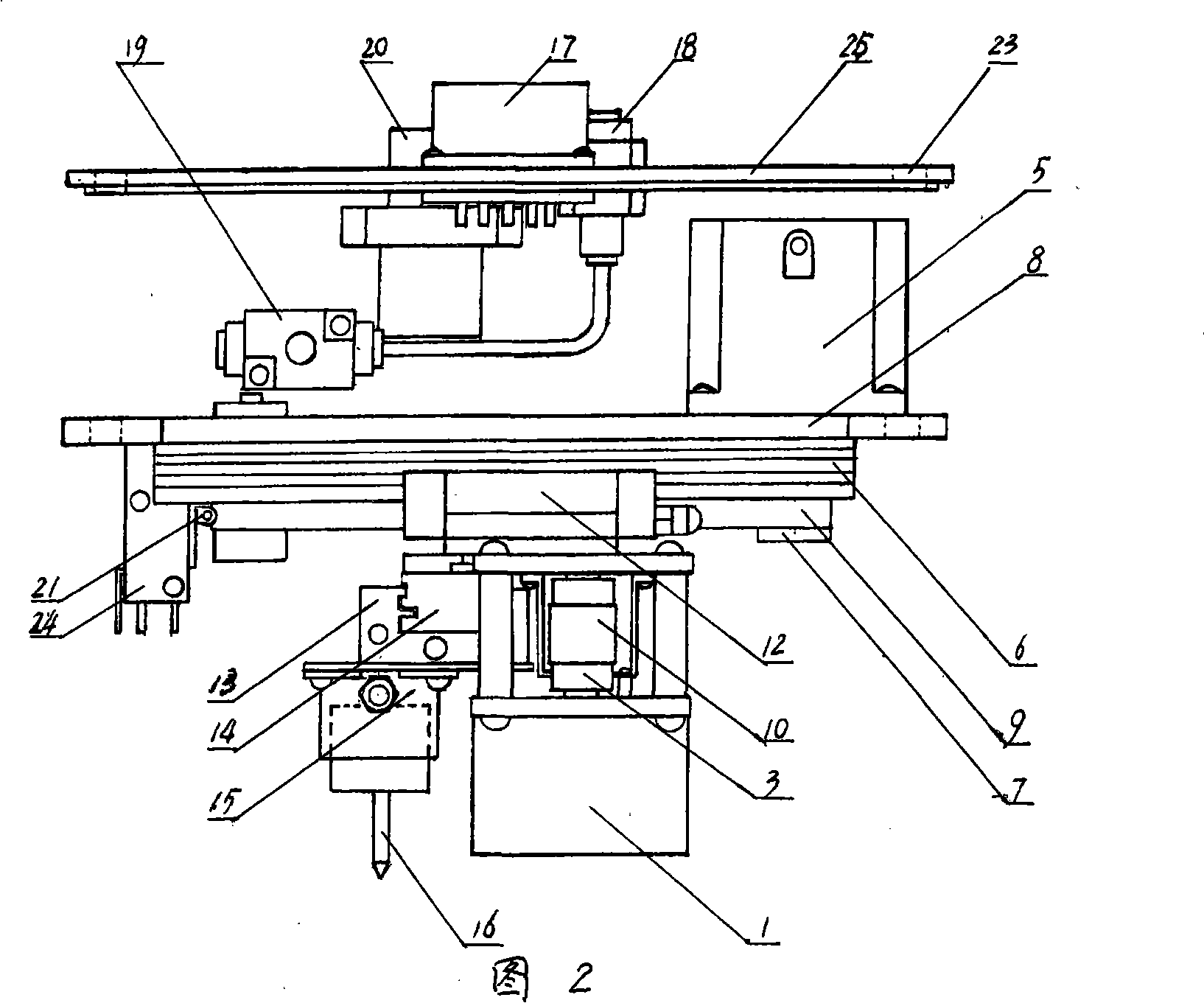

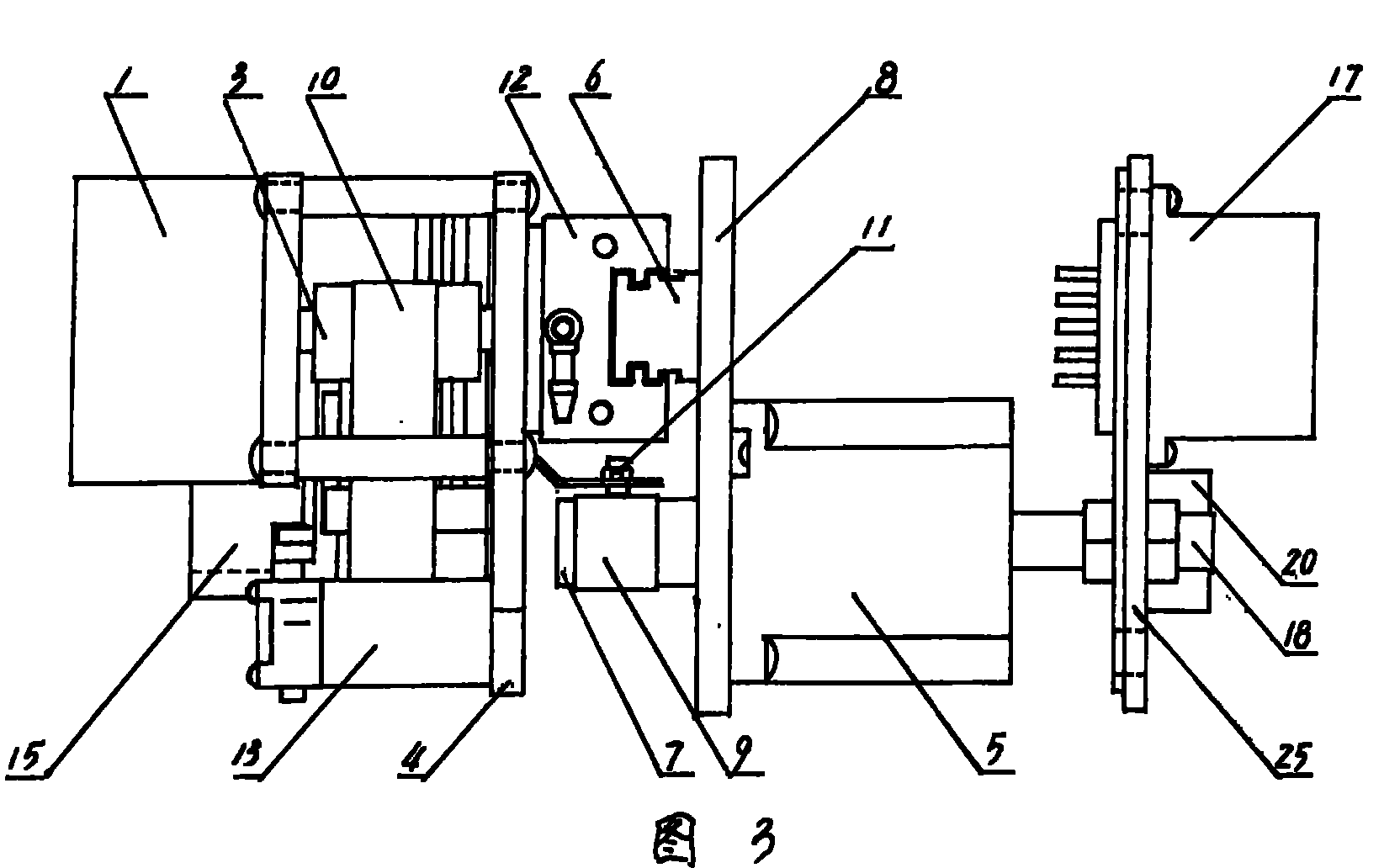

[0018] The present invention will be further described in conjunction with accompanying drawings.

[0019] The steel plate marking printer of the present invention is composed of a control system, a drive system, a printing system and connecting parts; the control system includes an external computer, a start switch, a 16-pin socket, and a limiter; the drive system includes a motor, a pneumatic valve and an air interface; The printing system includes needle bases, printing needles, x-axis and y-axis independent guide rails, slide rails, belts, pulleys, and connectors; connecting parts include cover plates, back plates, pressure plates, and pull rods.

[0020] Depend on figure 1 , figure 2 , image 3 It can be seen from the figure that one end of the Y-axis motor 1 , the Y-axis limiter 2 and the Y-axis pulley 3 is all fixed on the pressure plate 4 . The X-axis motor 5 , the X-axis guide rail 6 , the X-axis pulley 7 and the X-axis limiter 24 are installed on the backboard 8 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap