Paraffin alkylation

A technology of alkylation and alkylate, which is applied in the field of alkylation and can solve problems such as increasing octane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

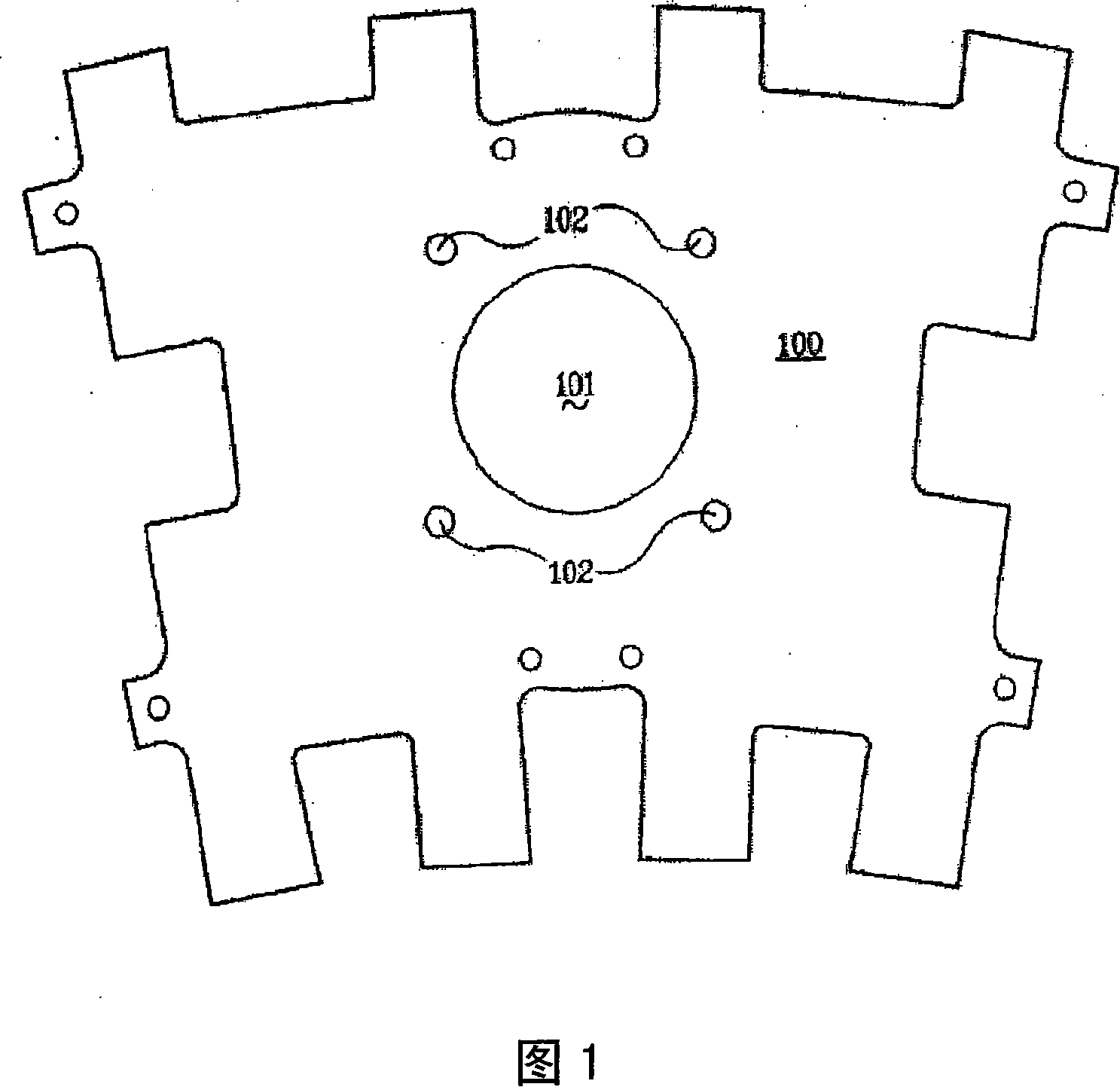

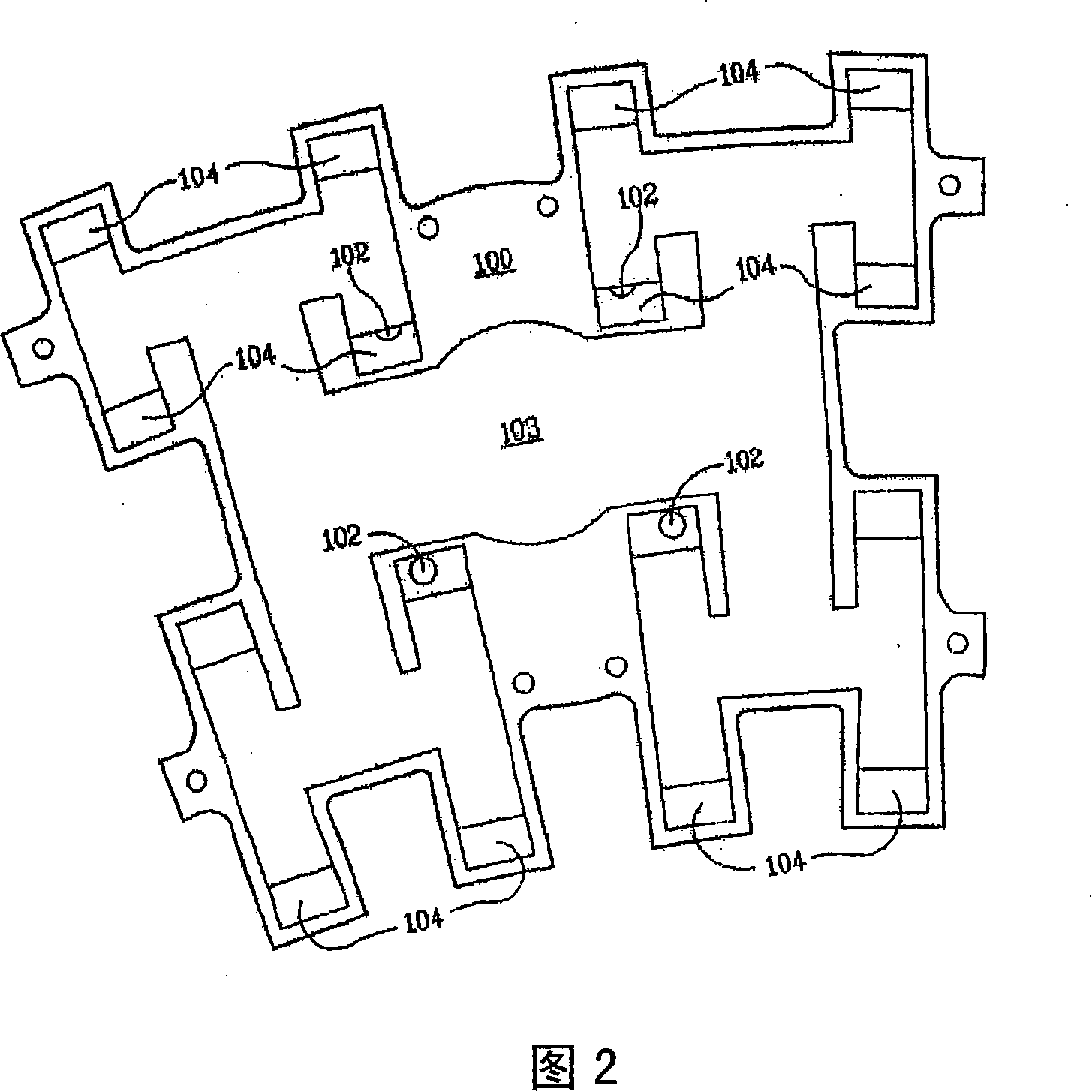

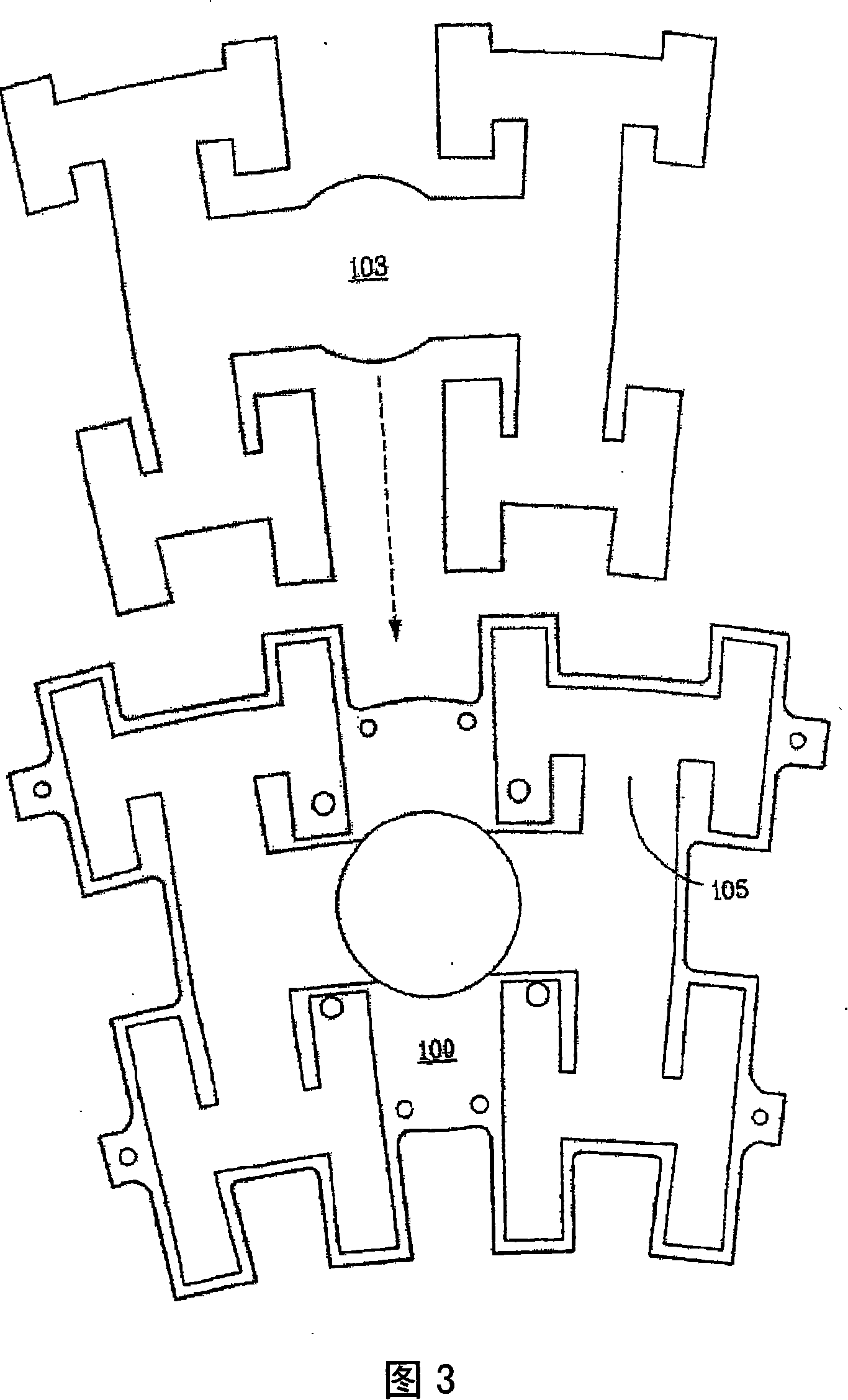

Image

Examples

Embodiment

[0078] To demonstrate the advantages of using a vaporization section in the overall process, a pilot setup was in which a single reactor was configured with a first mixing / reaction zone and a vaporization zone. The experimental device operates in the "transition" or "pulse" flow region in the vaporization zone. The test is run as follows:

[0079] a) the device is configured as a downflow reactor;

[0080] b) using a single packing section in which a total of 28 0.3m x 7.62cm (1 foot long x 3 inches) diameter packets were packed into the combined mixing zone (first reaction zone) and vaporization zone;

[0081] c) the packing used is provided in the mixing and vaporization zone for the continuous phase of acid and allows the continuous phase of hydrocarbons to leave the vaporization zone and enter the coalescer;

[0082] d) introducing liquid, recycle acid and hydrocarbons to the mixing zone;

[0083] e) using only one recycle hydrocarbon stream, which will reach the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com