Difference frequency type film acoustic wave resonator based micro-mass sensor

A bulk acoustic wave resonator, thin-film bulk acoustic wave technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc. The effect of overcoming influence, increasing sensitivity, increasing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

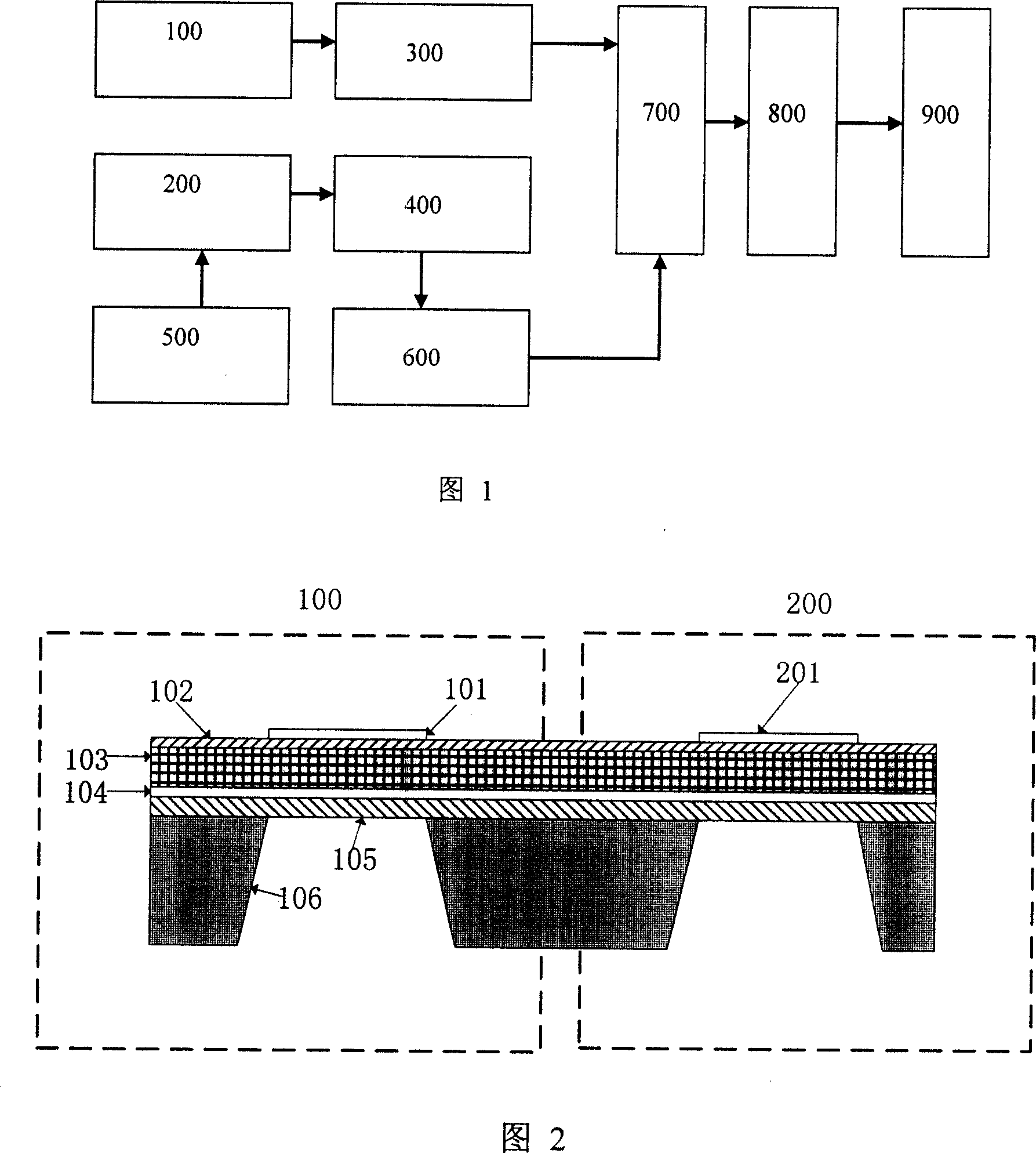

[0047] This embodiment will detail the use of the present invention as a micro-mass sensor (refer to FIG. 1). This embodiment includes a mass sensing thin film bulk acoustic resonator (FBAR) 100 for mass sensing, and a reference frequency Thin film bulk acoustic resonator (FBAR) 200, first high-frequency oscillation circuit 300, second high-frequency oscillation circuit 400, DC / DC DC boost bias circuit 500, high-frequency amplifier circuit 600, high-frequency mixing circuit 700, Low-pass filter circuit 800 and frequency measurement and display device 900;

[0048] The working principle of this embodiment is as follows: The mass sensing film bulk acoustic resonator (FBAR) 100 for mass sensing and the first high-frequency oscillation circuit 300 together form a first high-frequency oscillator to generate a high-frequency signal f 01 (E.g. f 01 = 1GHz). When the mass load on the mass sensing film bulk acoustic resonator (FBAR) 100 changes slightly, the frequency of the output signal ...

specific Embodiment approach

[0057] Example 1

[0058] This embodiment will detail the use of the present invention as a micro-mass sensor (refer to FIG. 1). This embodiment includes a mass sensing thin film bulk acoustic resonator (FBAR) 100 for mass sensing, and a reference frequency Thin film bulk acoustic resonator (FBAR) 200, first high-frequency oscillation circuit 300, second high-frequency oscillation circuit 400, DC / DC DC boost bias circuit 500, high-frequency amplifier circuit 600, high-frequency mixing circuit 700, Low-pass filter circuit 800 and frequency measurement and display device 900;

[0059] The working principle of this embodiment is as follows: The mass sensing film bulk acoustic resonator (FBAR) 100 for mass sensing and the first high-frequency oscillation circuit 300 together form a first high-frequency oscillator to generate a high-frequency signal f 01 (E.g. f 01 = 1GHz). When the mass load on the mass sensing film bulk acoustic resonator (FBAR) 100 changes slightly, the frequency of...

Embodiment 2

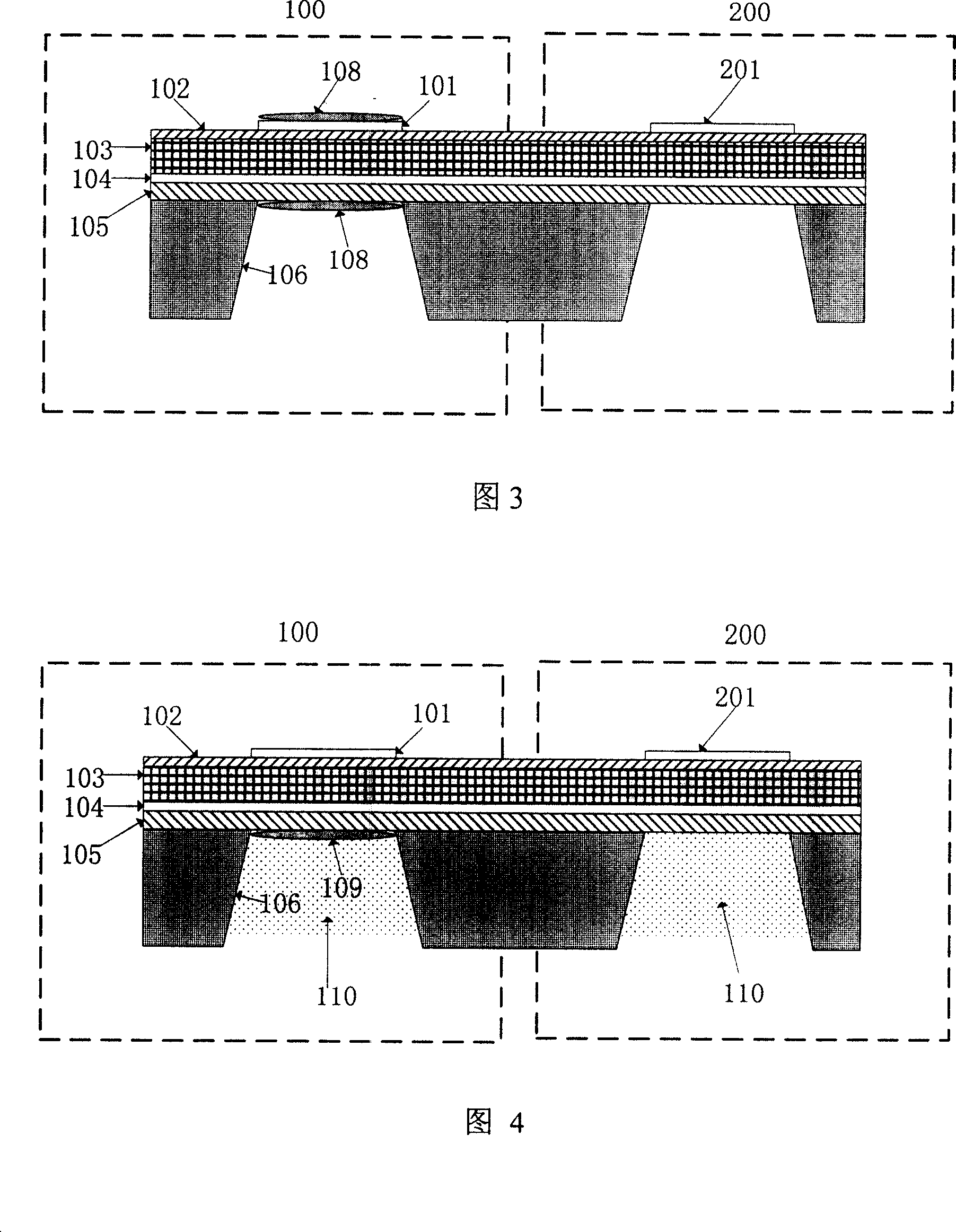

[0071] This embodiment will detail the application of the present invention as a selective substance mass sensing in a gas environment (refer to FIG. 3). The same parts as in Example 1 will not be repeated.

[0072] It can be seen from FIG. 3 that the mass sensitive area of the thin film bulk acoustic resonator (FBAR) 100 for mass sensing in this embodiment is the sensitive area of the upper electrode 101 and the support layer 105. A layer of selective gas adsorption membrane 108 is placed in the area. In actual applications, only the selective gas adsorption membrane 108 is exposed to the gas environment to be monitored, and other parts are isolated from the gas environment to be monitored.

[0073]When gas molecules to be adsorbed appear in the monitored gas environment, the selective gas adsorption film 108 adsorbs the gas molecules, and thus acts on the thin film bulk acoustic resonator (FBAR) for mass sensing The mass load of 100 increases, thereby causing the resonant fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com