Hydraulic pressure turn-over device of large-scale component

A technology of hydraulic flipping and large components, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of structural damage, insecurity, difficulty in crane control, etc., and achieve the effects of low equipment cost, convenient maintenance, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

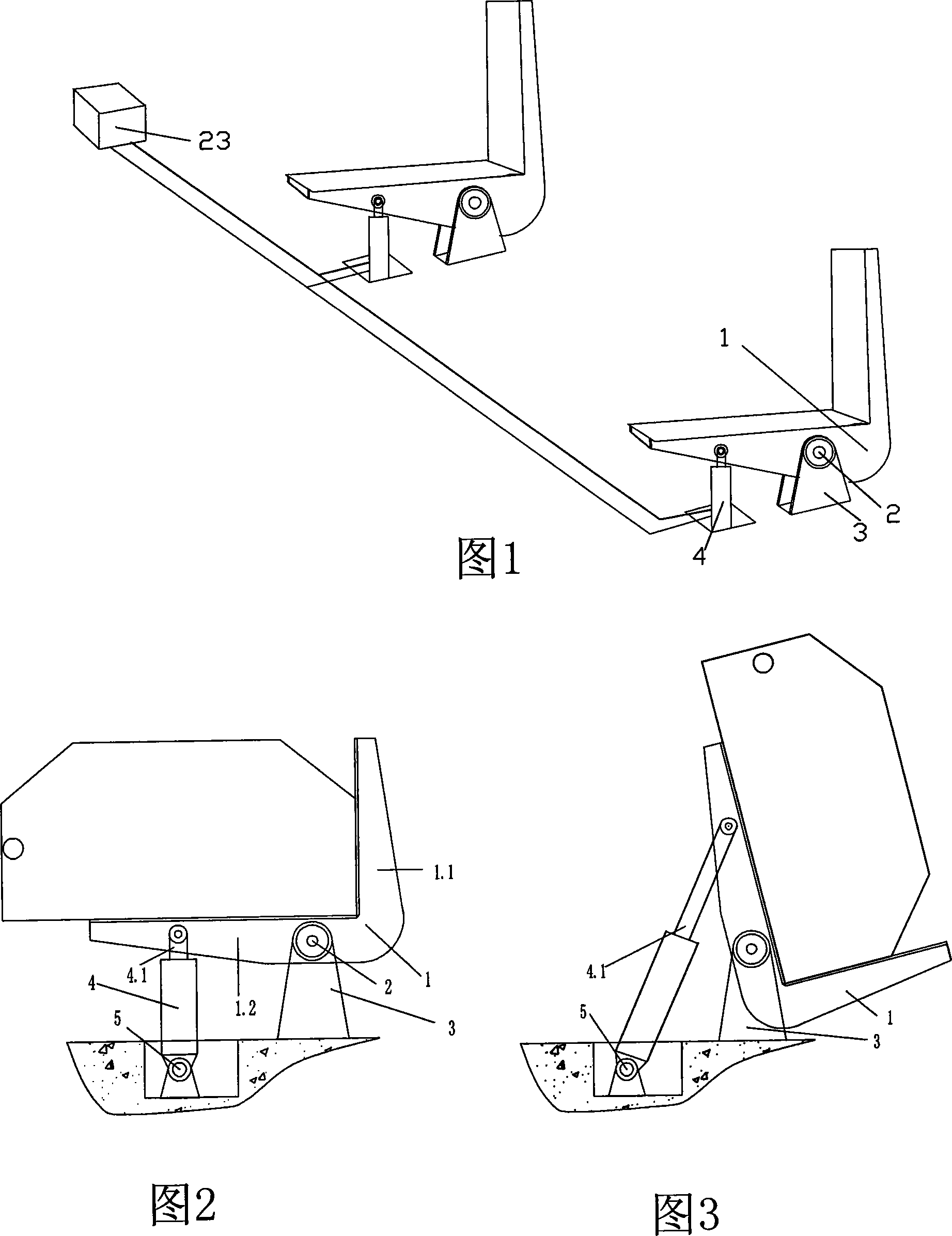

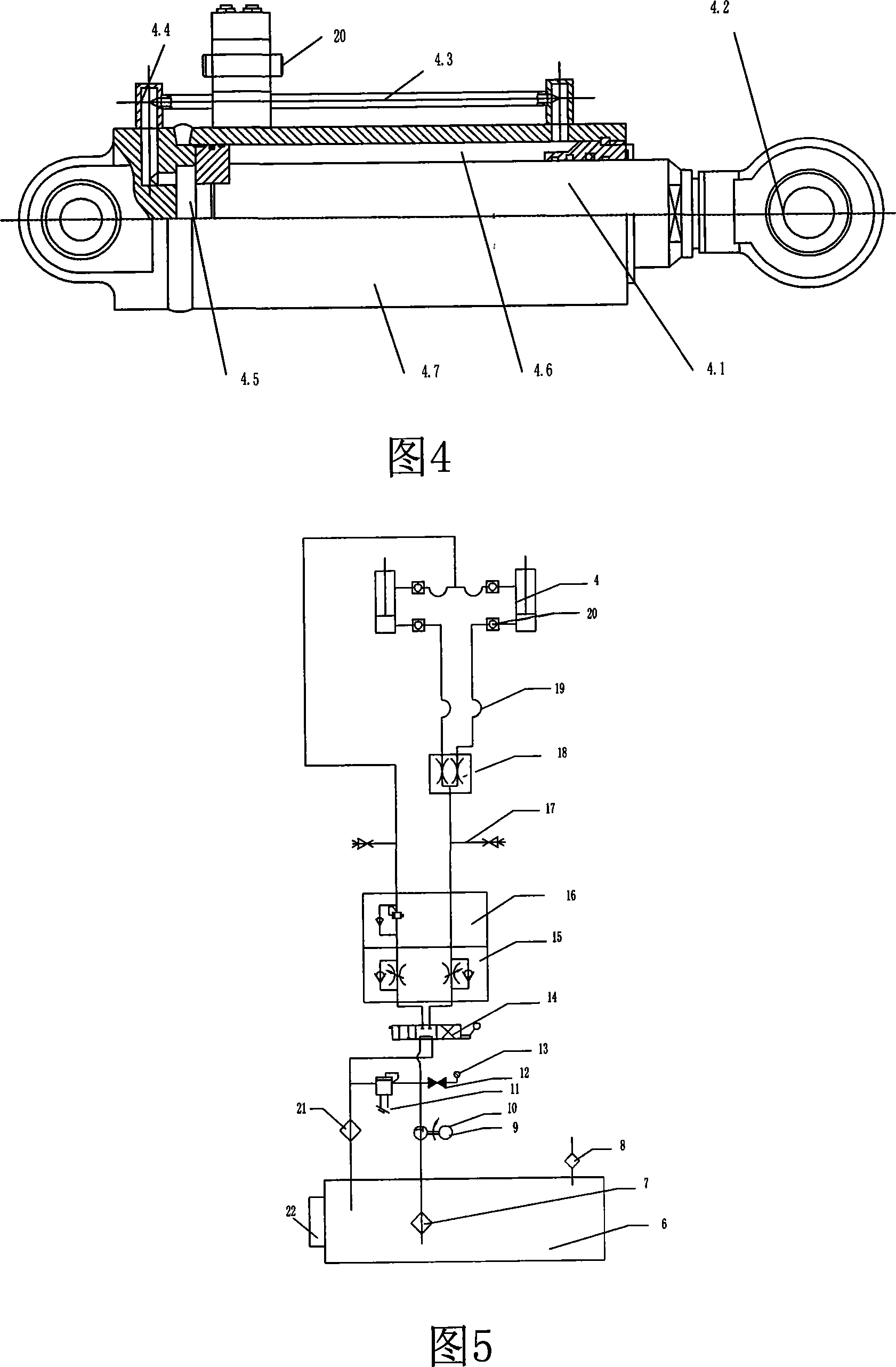

[0012] Referring to the accompanying drawings, the present invention consists of at least two sets of side-by-side turning mechanisms. The turning mechanism includes an L-shaped load-bearing rotating body 1. The load-bearing rotating body has a short arm 1.1 and a long arm 1.2. The long arm is provided with a rotary hinge 2. The load-bearing rotating body The rotary hinge is hinged with the fixed hinge seat 3, the long arm is also hinged with the piston rod 4.1 of the lifting cylinder 4, the other end of the lifting cylinder is hinged with the hydraulic hinge seat 5, and the lifting cylinder is connected with the hydraulic control device through a pipeline; the hydraulic station is mainly composed of hydraulic The control device consists of a hydraulic control device including a fuel tank 6, an oil suction filter 7, a motor 9, an axial piston pump 10, a pilot relief valve 11, a manual reversing valve 14, a double one-way throttle valve 15, and a superposition type Back pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com