Synchronous padding method for raw spinning cake

A raw silk and silk cake technology, applied in liquid/gas/vapor yarn/filament processing, dumping textile material processing, etc., can solve the problem that the difference between the upper and lower layers of the pressure washing car affects the dyeing quality, the long processing time after spinning, and the silk cake. High labor intensity and other problems, to achieve the effect of reducing energy and resource consumption, low cost, and short refining cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

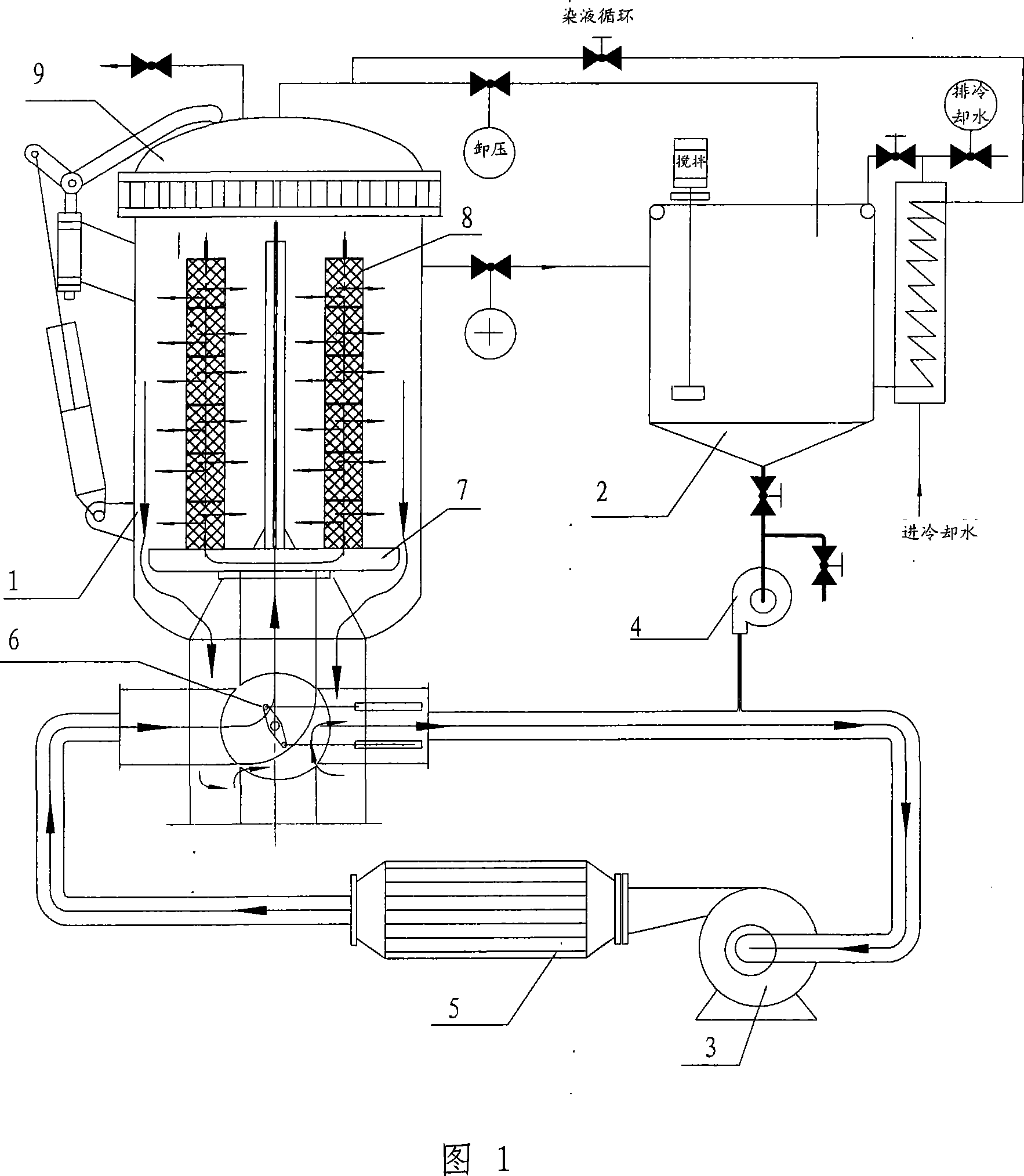

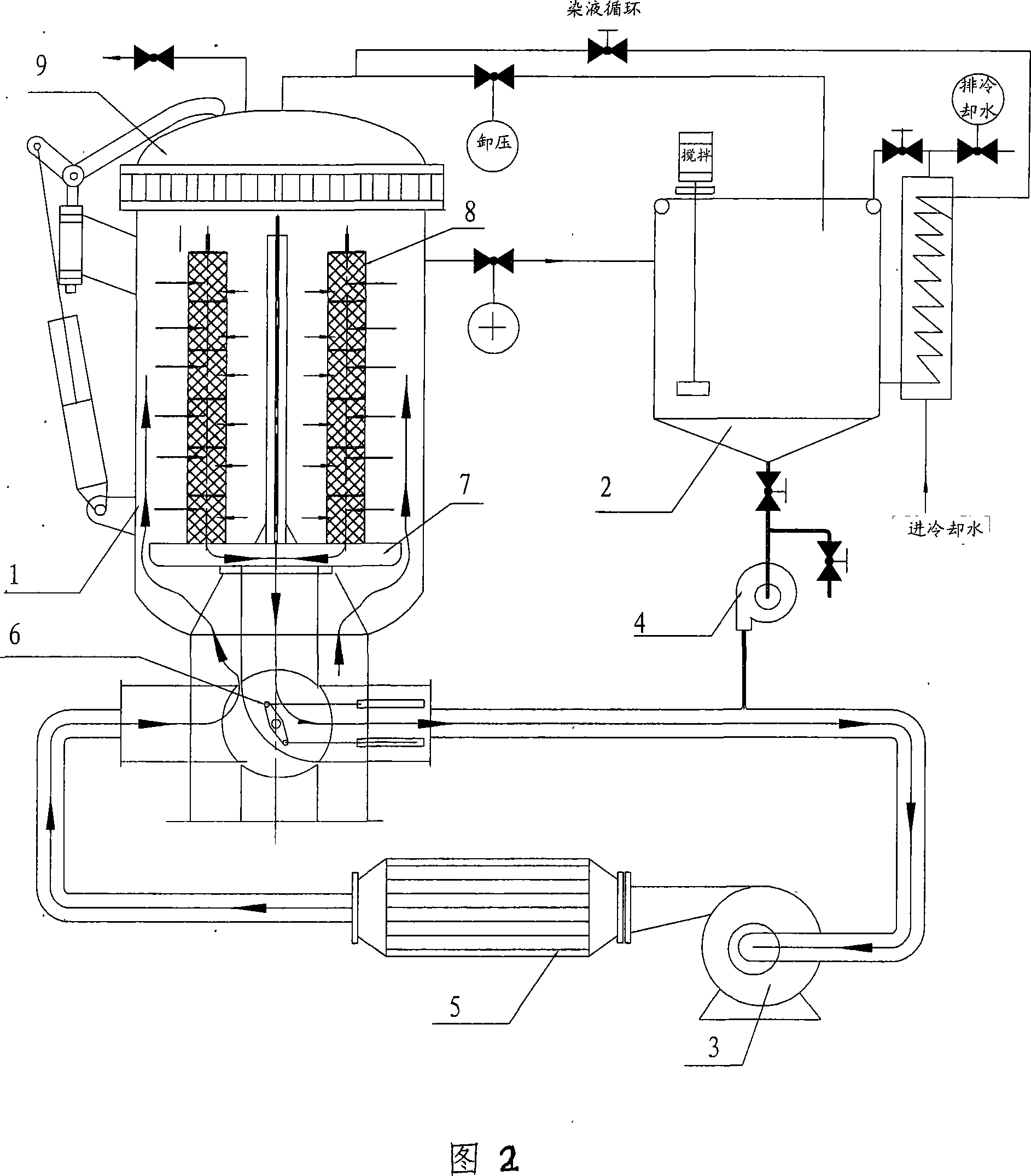

[0045] The simultaneous pressure dyeing method proposed by the present invention is to combine the pressure washing and dyeing of the raw silk cake into one set of processes, and complete the pressure washing and dyeing in one device (dye vat). This method is especially suitable for viscose filaments. Pie dyeing needs.

[0046] The specific improvement implementation plan is as follows:

[0047] 1. Process optimization: the post-treatment and the hot water washing before dyeing are combined at the same time, and the production process is reduced from the original 11 steps to 7 steps. The before and after process comparison is as follows:

[0048] Original production process: raw silk cake→transfer→filament loading→post-spinning treatment (press washing: water washing→dezincification→water washing→desulfurization→water washing→bleaching→water washing)→dehydration→transfer→loading liner→loading creel→incoming Cylinder → hot water washing → overflow water washing → dyeing.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com