Glass fibre foaming wallhanging

A glass fiber cloth and glass fiber technology, which is applied in the field of glass fiber foam wall cloth, can solve the problems of acid and alkali resistance, low tensile and tear strength, difficult to reflect the decorative three-dimensional effect, etc., and achieve good tensile strength. Tear strength, excellent scrub resistance, ideal acid and alkali resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

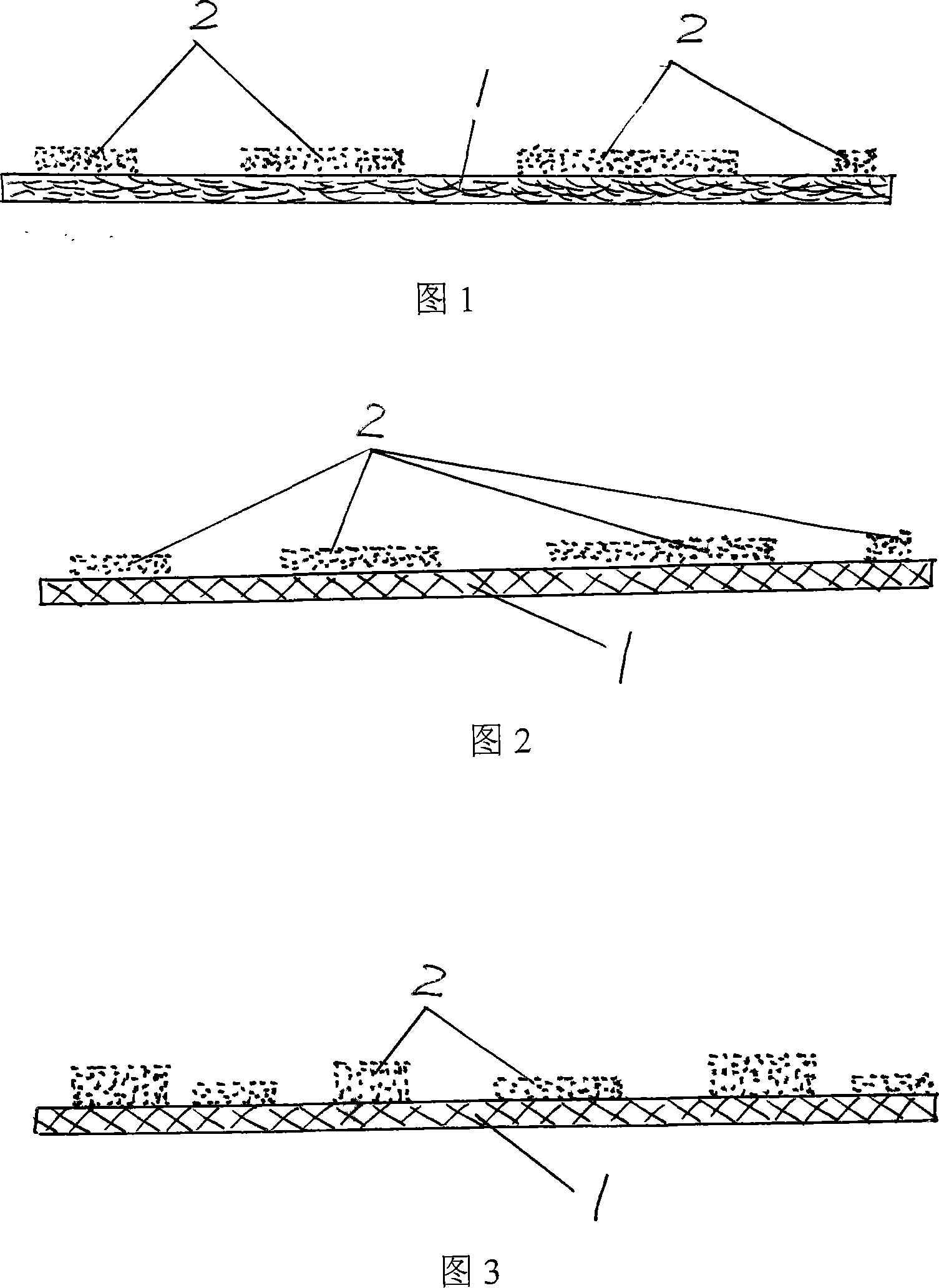

[0013] Please refer to Figure 1. Use a commercially available or self-made non-woven glass fiber cloth as the bottom layer 1. The non-woven glass fiber cloth referred to here is a cloth known in the industry that does not have warp and weft. It is made of non-woven machinery such as Needle punching machine entangles glass fiber to obtain it, or it is obtained by gluing, and its weight can be selected according to the requirements of use or the requirements of users. The molten polyethylene is foamed to one side surface of the bottom layer 1 by a foaming process, and a pattern 11 protruding from the surface of the bottom layer 1 to about 0.5 mm is formed on one side surface of the bottom layer 1, thereby forming the foamed layer 2. The pattern 11 can be It is a regular pattern, an irregular pattern, or a pattern that has both regular patterns and irregular patterns.

Embodiment 2

[0015] Please refer to Figure 2. A commercially available or self-made woven glass fiber cloth is used as the bottom layer 1. The woven glass fiber cloth referred to here is a weaving machine known in the industry from warp and weft. It is composed of continuous glass fiber yarns interlaced, and the interlaced form can be plain interlaced or twill interlaced. In addition, the woven glass fiber cloth can be processed into a grid-like structure as needed. The molten polyethylene is foamed and bonded to one side surface of the bottom layer 1 by a foaming process, and a foam layer 2 is formed on one side surface of the bottom layer 1 with a 12 mm pattern 11 and text 12 protruding from the surface of the bottom layer 1.

Embodiment 3

[0017] Please refer to Figure 3, the molten polyethylene is foamed to one side surface of the bottom layer 1 by foaming. On one side surface of the bottom layer 1, there are formed 5mm and 18mm protrusions on the surface of the bottom layer 1 and presented in the form of pattern 11.泡层2。 Foam layer 2. In this embodiment, the foamed layer 2 can exhibit a more three-dimensional effect with a staggered height on one side surface of the bottom layer 1. The rest is the same as the description of Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com