Vertically arranged transmission device of minitype wheeled tractor

A technology for a wheeled tractor and a transmission device, applied in the field of tractors, can solve the problems of high manufacturing cost, high selling price, and increased sales of direct transmission, and achieve the effects of saving transmission pairs and related parts, improving transmission efficiency, and reducing transmission links.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

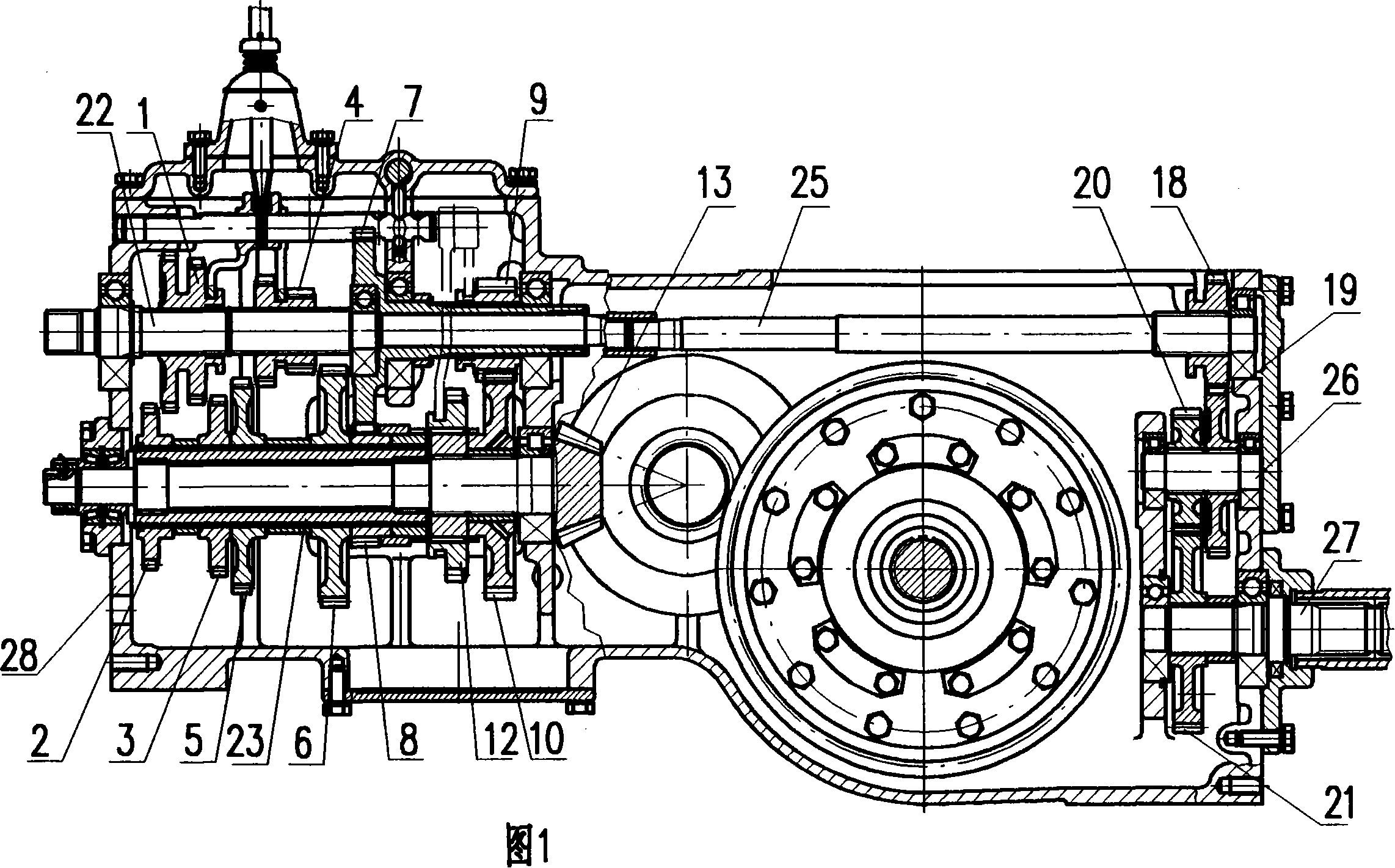

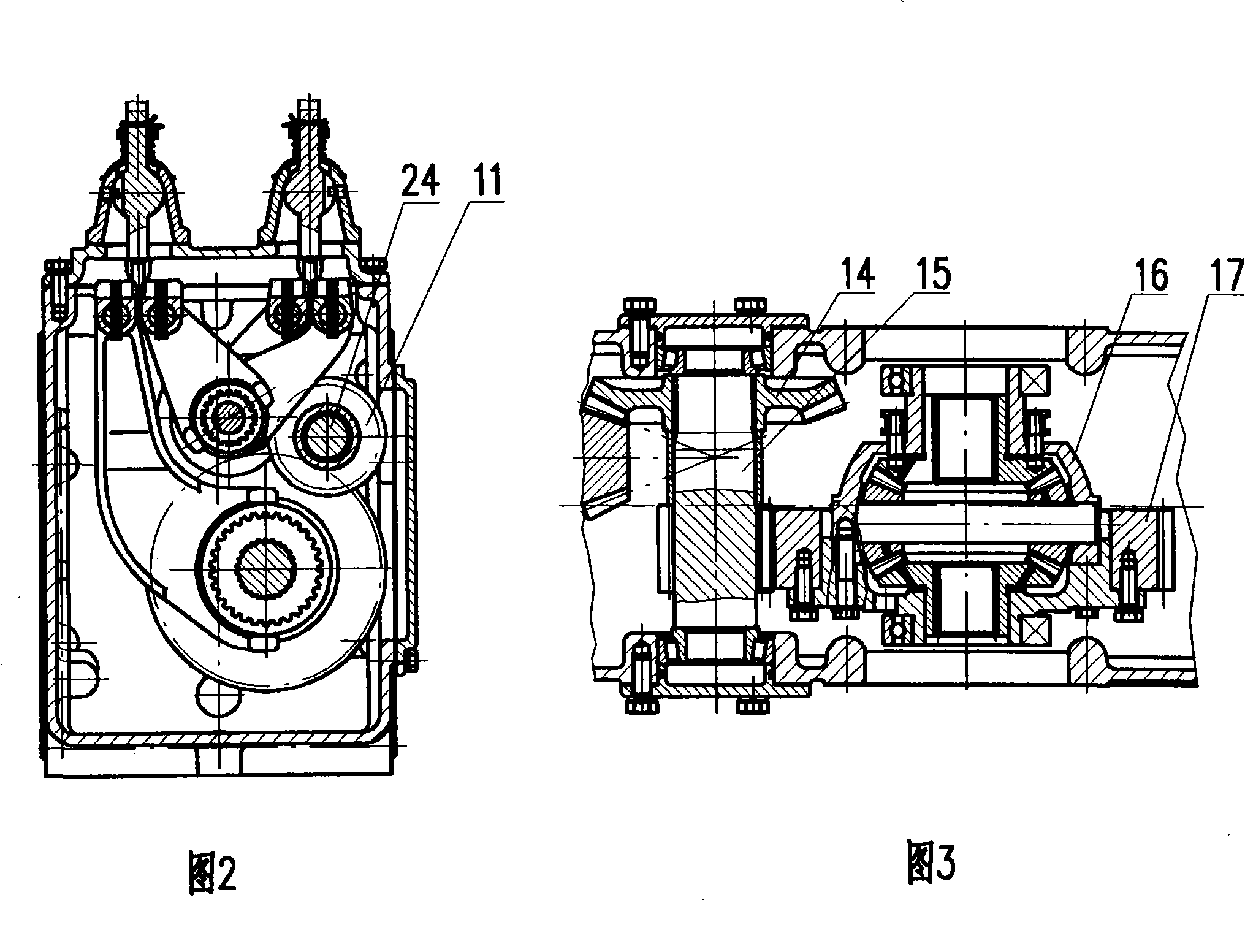

[0011] The small wheeled tractor longitudinal transmission shown in Figure 1, Figure 2, and Figure 3 includes III-IV gear driving gear 1, IV gear driven gear 2, III gear driven gear 3, and I-II gear driving gear 4. II gear driven gear 5, I gear driven gear 6, primary reduction driving gear 8, primary reduction driven gear shaft 7, secondary reduction driving gear 9, secondary reduction driven gear 10, middle reverse gear Gear 11, reverse driven gear 12, small bevel gear shaft 13, large bevel gear 14, final drive driving gear shaft 15, differential 16, final drive driven gear 17, power output transition gear 18, power output intermediate gear 19 , power output driving gear 20, power output driven gear 21, first shaft 22, driven shaft 23, reverse gear shaft 24, power output driving shaft 25, power output idler shaft 26, power output shaft 27, gearbox housing 28 and other main parts, wherein the large bevel gear 14 is combined with the final drive driving gear shaft 15 as a whole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com